Pure radial supersonic micro-turbine structure with air bearing

A technology of air bearings and micro turbines, which is applied in the direction of supporting elements of blades, machines/engines, stators, etc., can solve problems such as complex flow field structures, and achieve the effect of reducing the difficulty of design and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

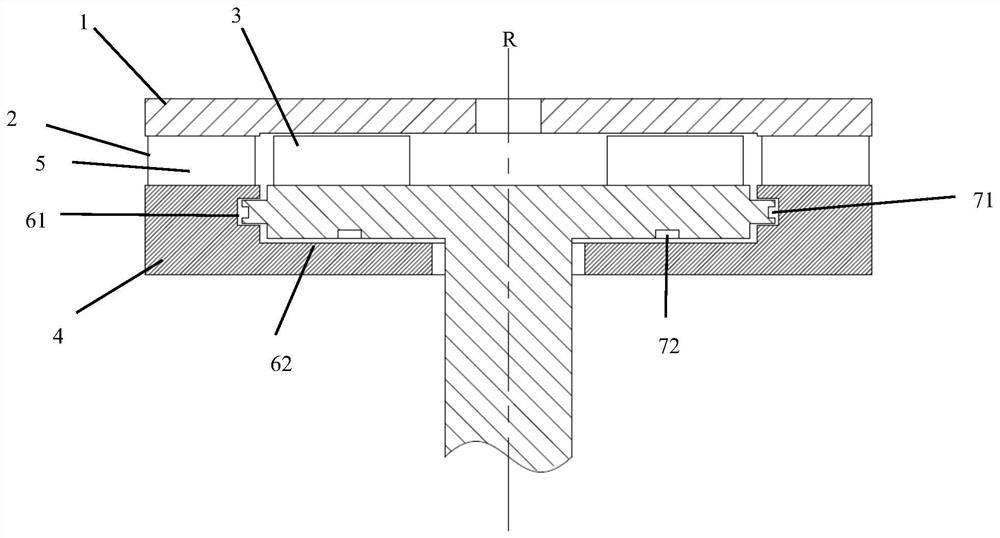

[0030] like figure 1 shown, the structure includes:

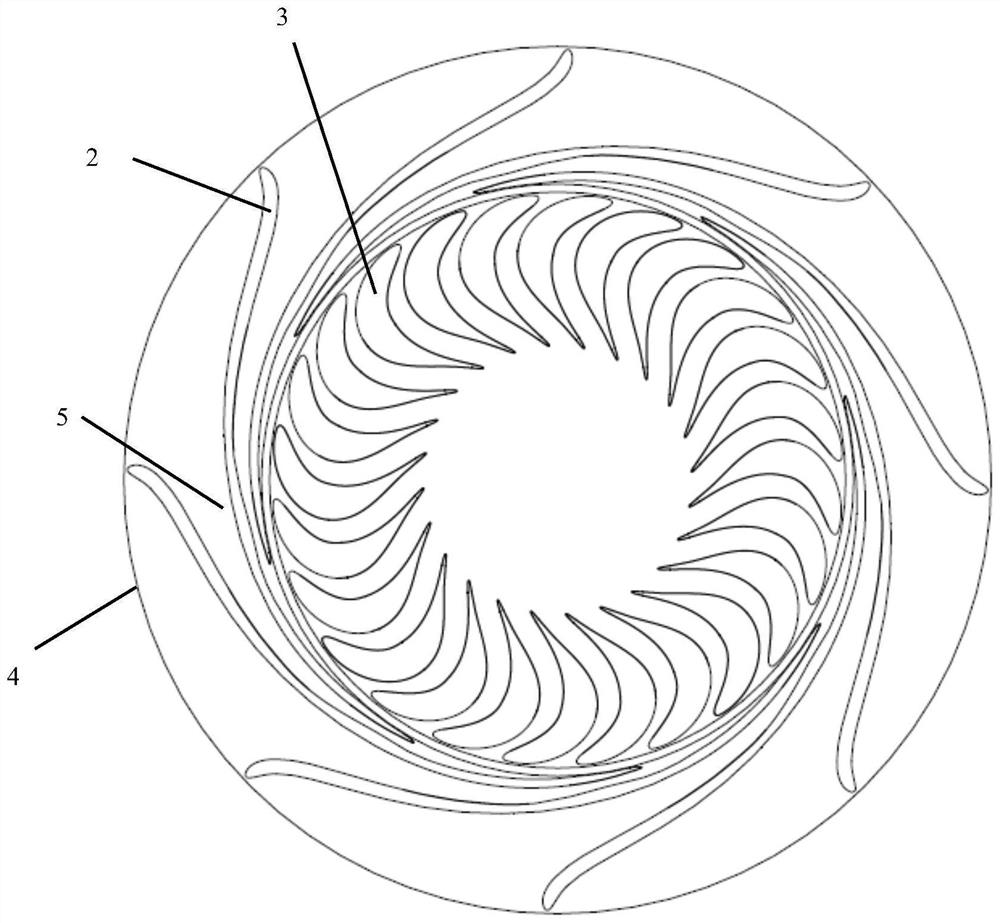

[0031] The upper casing 1 and the lower casing 4, the stator blade 2 and the rotor impeller 3 are sandwiched between the upper casing 1 and the lower casing 4, the rotor impeller 3 rotates around the rotation axis R, the stator blade 2 Each two pieces cooperate with the upper and lower casings to form a stator airflow channel 5, and the rotor impeller 3 cooperates with the lower casing 4 to form a dynamic pressure air bearing flow channel.

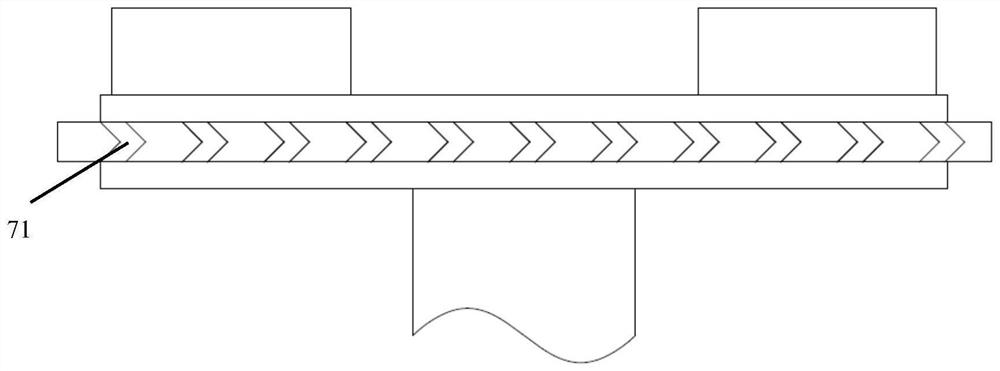

[0032] Among them, the dynamic pressure air bearing flow channel includes a radial dynamic pressure air bearing flow channel 61 and a thrust pressure air bearing flow channel 62 . Dynamic pressure gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com