A vacuum coating unshielded sample flipping device

A vacuum coating and flipping device technology, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems that the film deposition cannot be completed, and there cannot be any shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation modes and specific operation processes, but the protection scope of the present invention is not limited to the following implementations example.

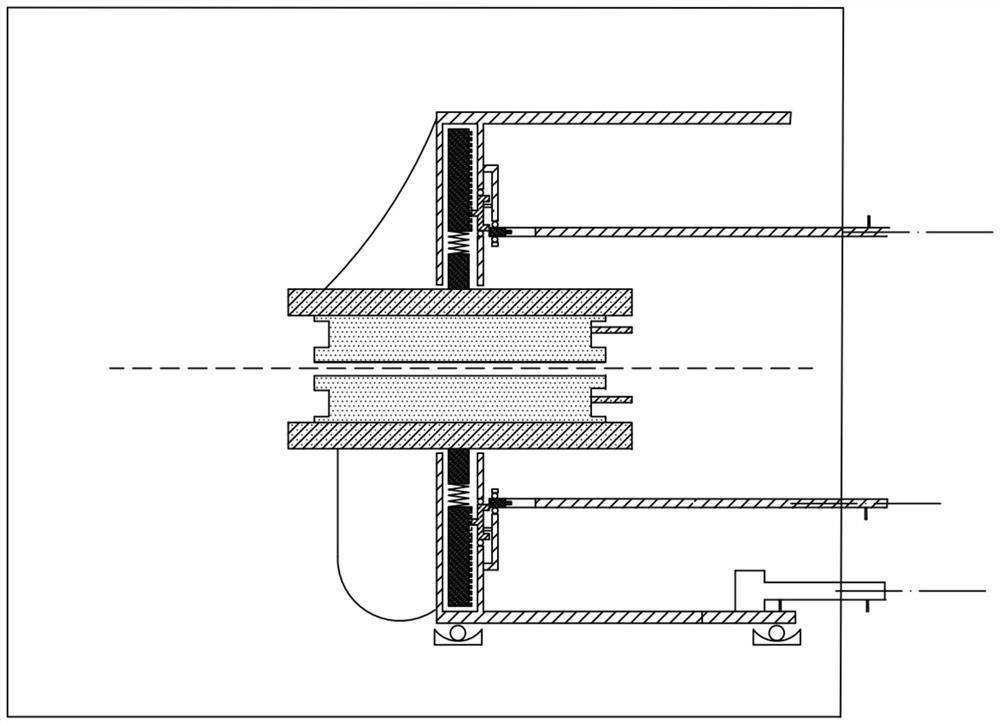

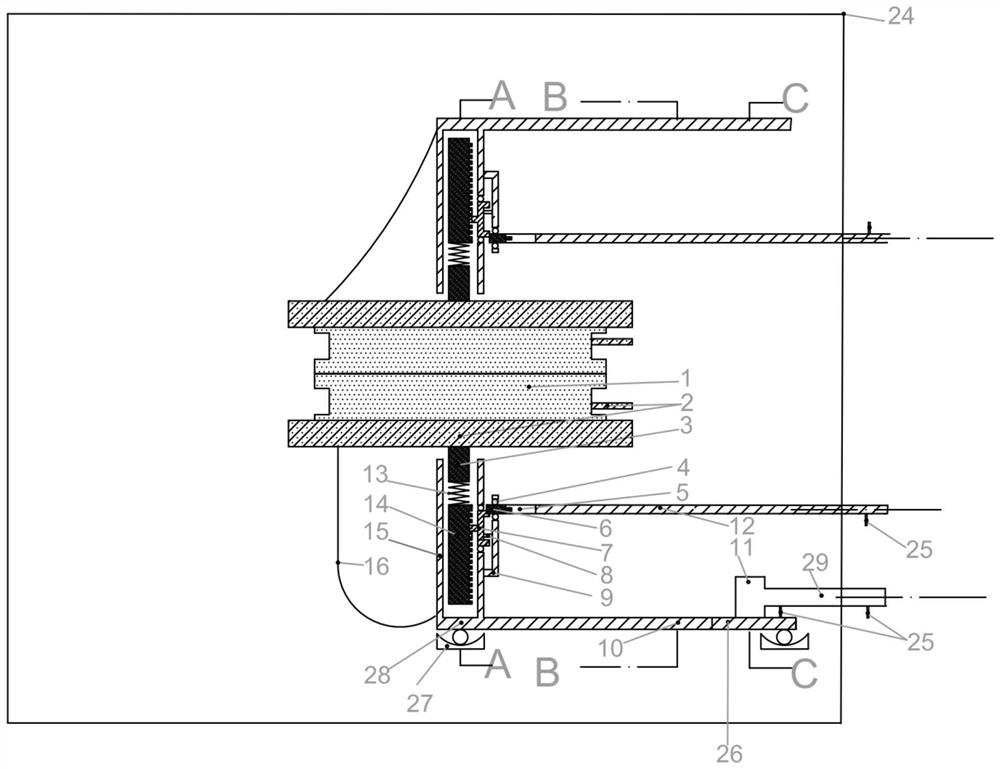

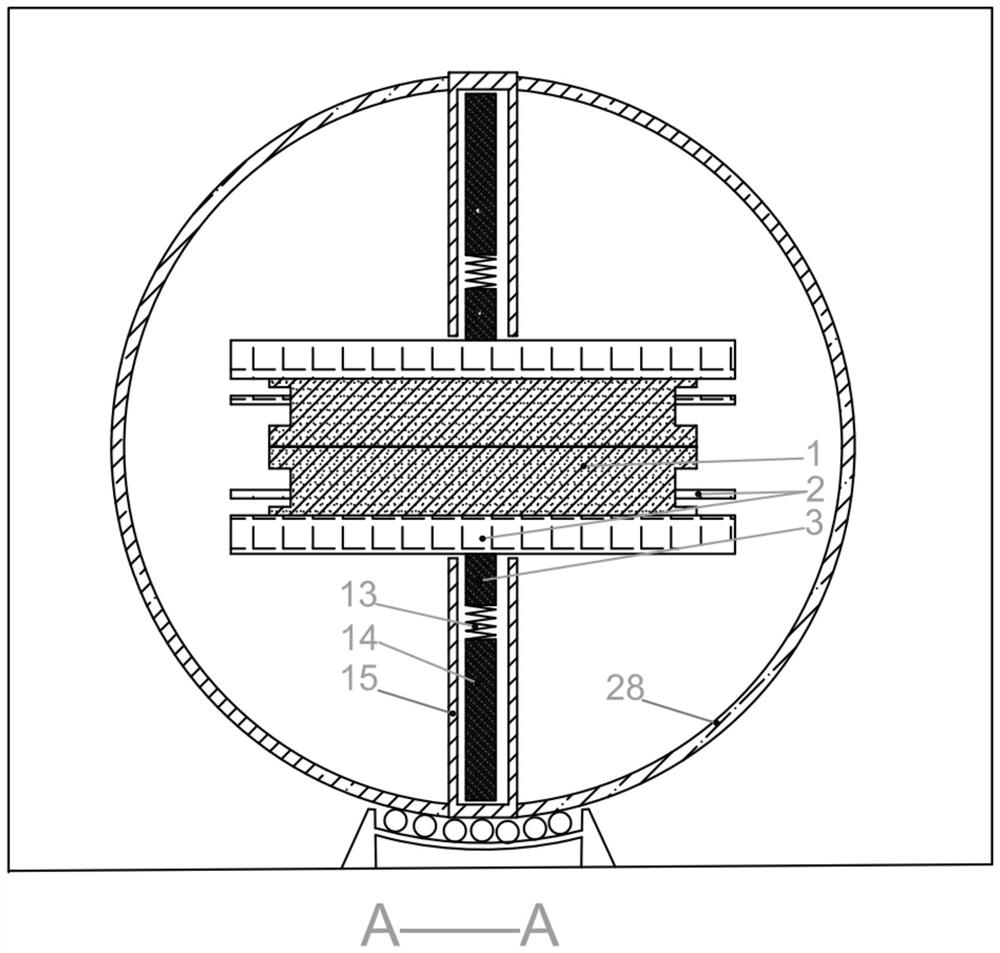

[0031] like Figures 1 to 7 As shown, this embodiment provides a technical solution: an unobstructed sample inversion device for vacuum coating, including two parts that are symmetrical up and down (see figure 1 ),

[0032] Each part includes a sample stage 1, a sample fixing base 2, a base-fixing telescopic rod assembly (3, 13 and 14), a telescopic rod limit cylinder 15, a telescopic rod secondary drive wheel 7, a driving wheel brake 8, and a telescopic rod The primary drive wheel 6, the splint assembly 5, the splint assembly power transmission shaft 12, the telescopic rod assembly fixing rod 10, the rotating seat 26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com