Welded nut drawing force performance detection device

A detection device, welding nut technology, applied in the measurement device, using stable tension/pressure to test material strength, strength characteristics, etc., can solve the problems of ugliness, product safety performance failure, etc., and achieve reliable test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

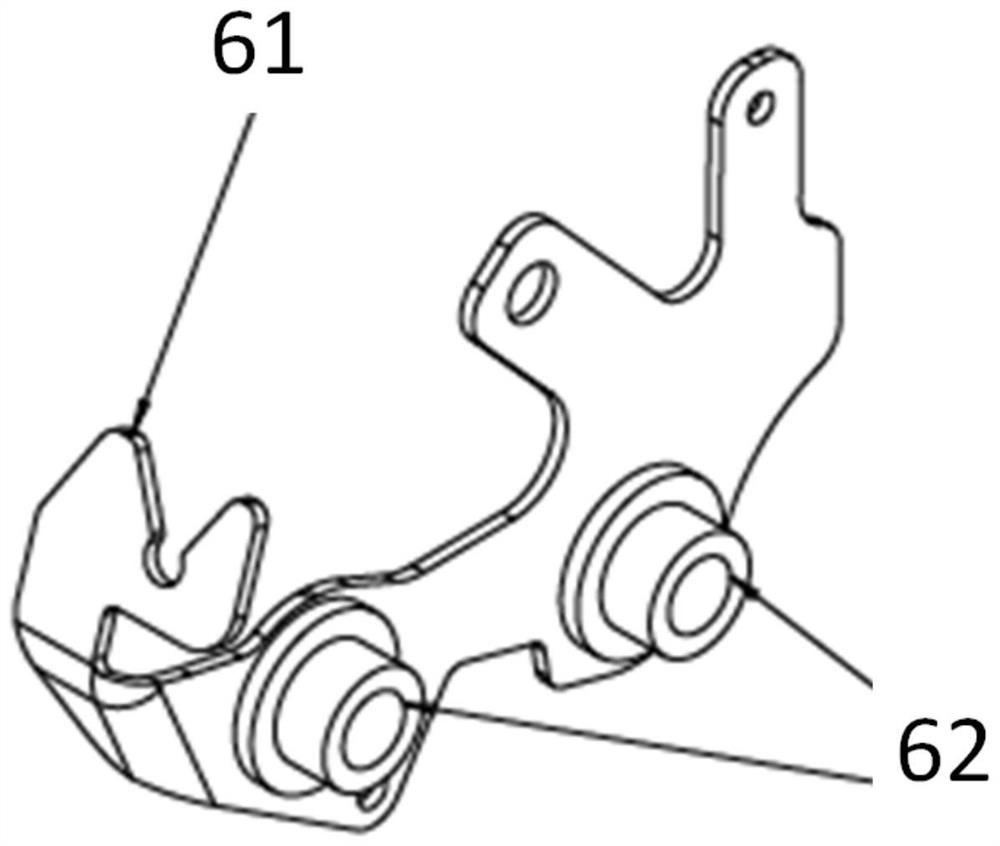

[0036] In this embodiment, the product performance after welding of the product 6 to be tested must meet the breaking torque of 60Nm, the pulling force of 8KN, and the welding nut does not fall off. The following is only for the evaluation of the pull-out force performance.

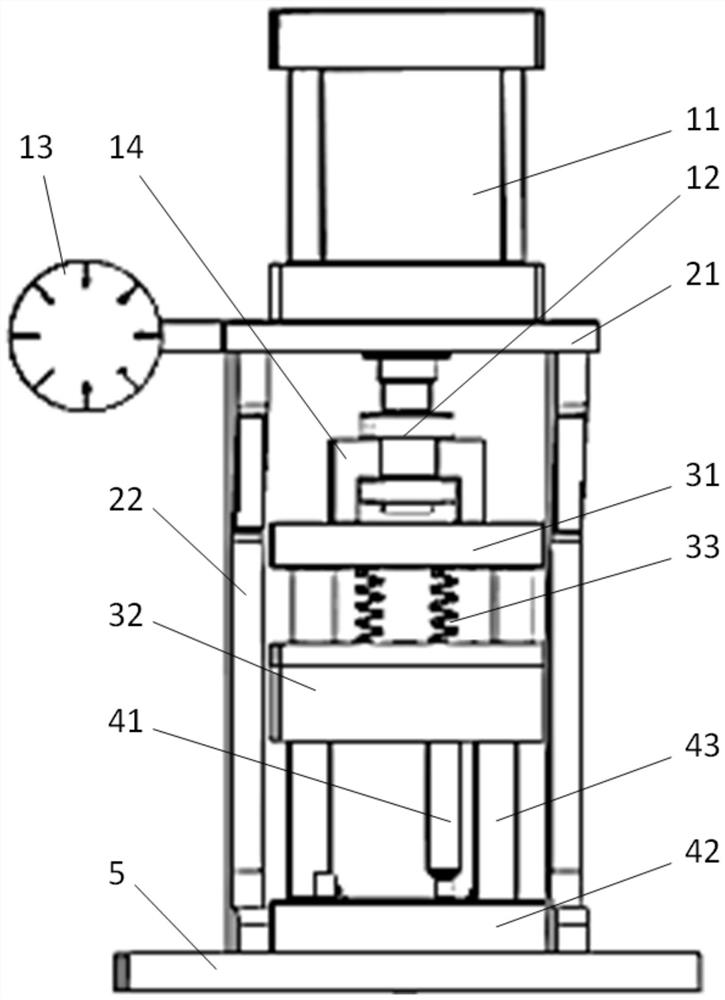

[0037] A device for testing the pullout force performance of weld nuts, such as Figure 1-2 , the product 6 to be tested includes a negative plate 61 and a nut 62 welded on the negative plate 61, the device includes: a pressurizing mechanism for providing detection power; a force transmission mechanism for transmitting the detection power to the nut 62; a support mechanism, It is used to support the pressurization mechanism; the product positioning plate 42 is used to fix the product to be tested; the pressurization mechanism is connected with the force transmission mechanism, at least one thimble 41 is arranged below the force transmission mechanism, and the product positioning plate 42 is provided with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com