Large-span pipe truss self-balancing slope sliding method

A pipe truss and large-span technology, which is applied in the field of self-balancing inclined-plane sliding of large-span pipe trusses, can solve the problem of large-span arched stockyard horizontal slip, large lateral horizontal force, unsafe sliding of sliding shoe board rails, etc. problems, to achieve the effect of reducing production and installation construction procedures, shortening the construction period, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

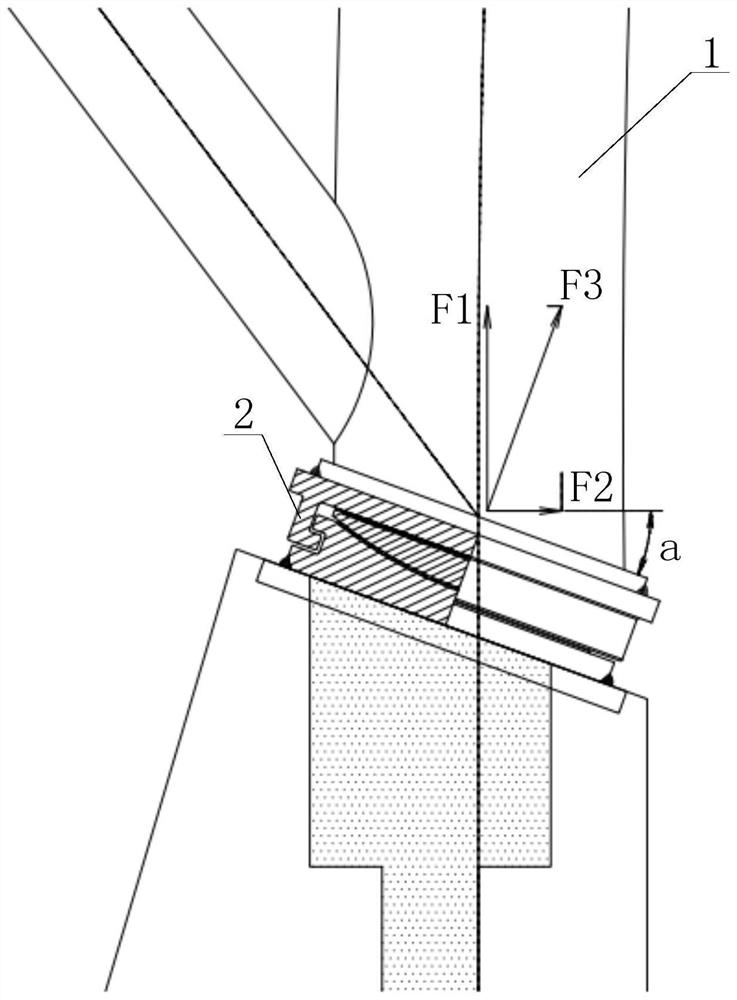

[0017] Below according to the accompanying drawings figure 1 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0018] see figure 1 , a self-balancing slope sliding method of a large-span pipe truss according to an embodiment of the present invention, comprising the steps of:

[0019] S1: Set the large-span pipe truss 1 on several oblique supports 2, the slope of the oblique support 2 fits with the bottom surface of the arch foot of the large-span pipe truss 1, and the slope of the oblique support 2 forms a support inclination angle a with the horizontal plane ;

[0020] S2: Determine and adjust the support inclination angle a of the oblique support 2 to the optimum slip angle to offset and reduce the lateral horizontal thrust F2 of the arch foot;

[0021] The S2 step further comprises the steps of:

[0022] S21: Calculate the vertical suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com