Full-automatic packaging machine

A fully automatic packaging machine and frame technology, applied in packaging and other directions, can solve the problems of cloth change, low efficiency, single folding method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

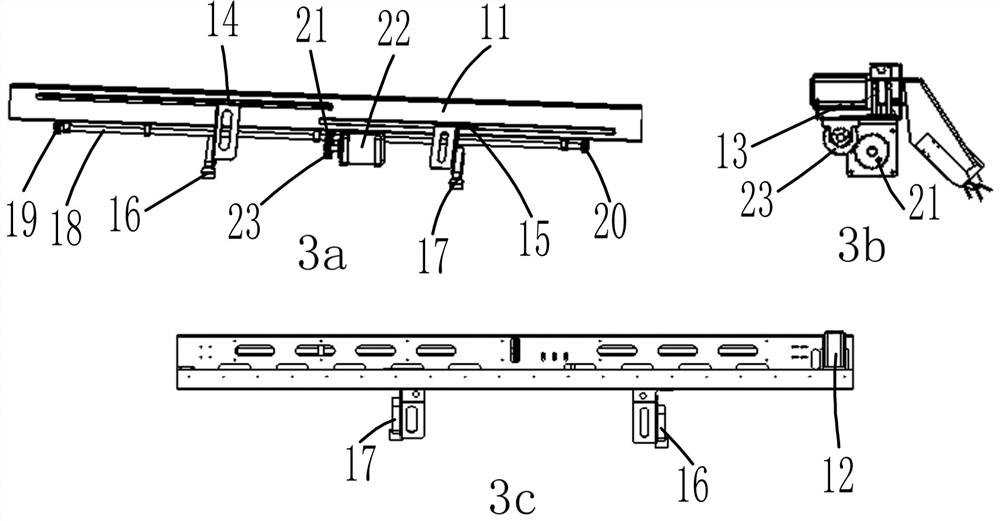

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

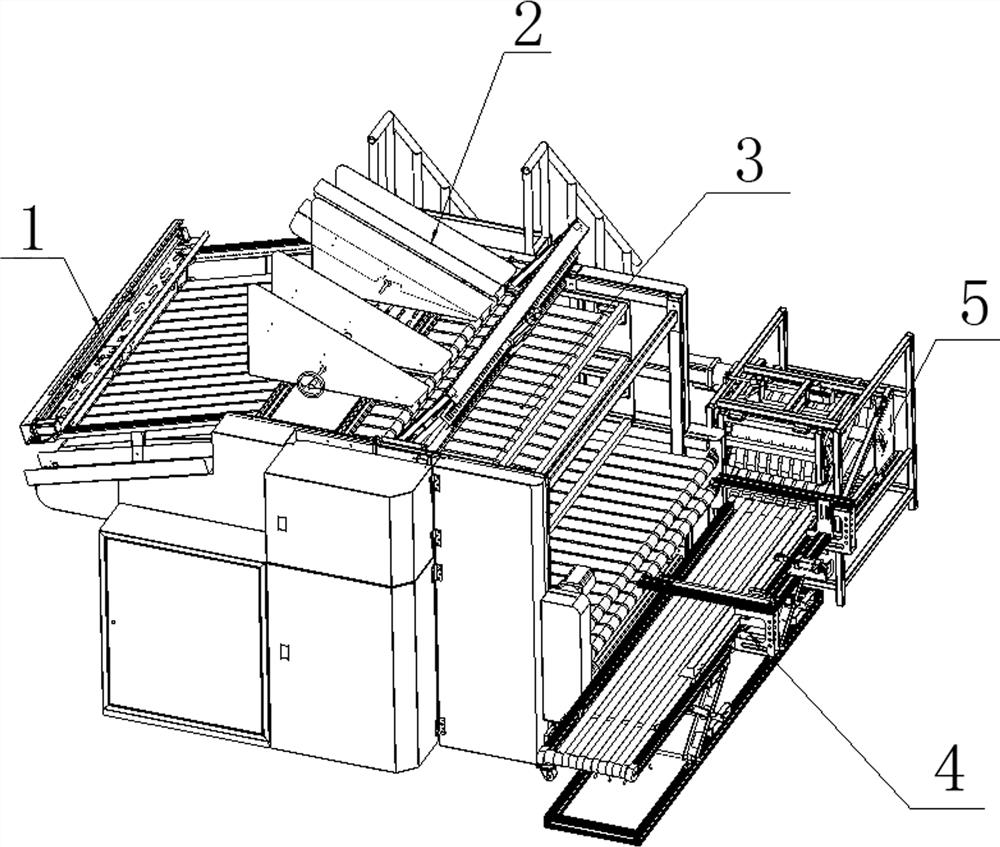

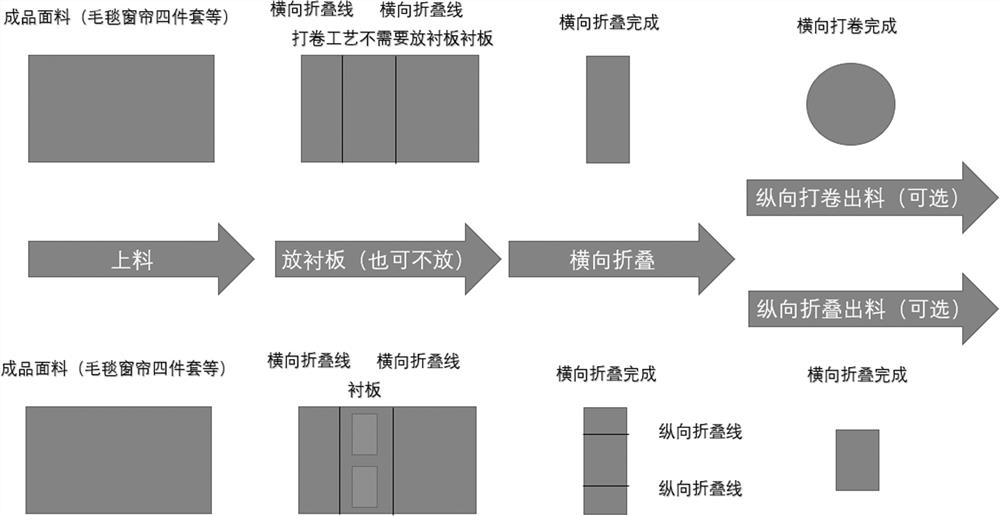

[0037] refer to Figure 1 to Figure 11 , a fully automatic packaging machine, which can automatically fold and roll cloth products, including but not limited to blankets, curtains, four-piece sets, small quilts and other home textile products, and can also realize automatic lining when cloth products are folded.

[0038] It includes a frame, which is sequentially installed with a feeding unit 1, a lining board unit 2, a folding unit and a discharging unit 5; the feeding unit 1 is installed above the feeding end of the folding unit, and the lining board unit 2 is set Above the folding unit, the discharging unit 5 is arranged at the discharging end of the folding unit. Usually, if the cloth does not need to be lined when it is folded, the liner unit 2 can be stopped separately. In addition, if the cloth needs to be rolled or folded, the discharge unit 5 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com