High-speed ink-jet screen making machine

An inkjet, screen machine technology, applied in printing and other directions, can solve the problems of reduced moving speed, reduced inkjet accuracy, product manufacturing failure, etc., to prevent ink breakage and ensure inkjet accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

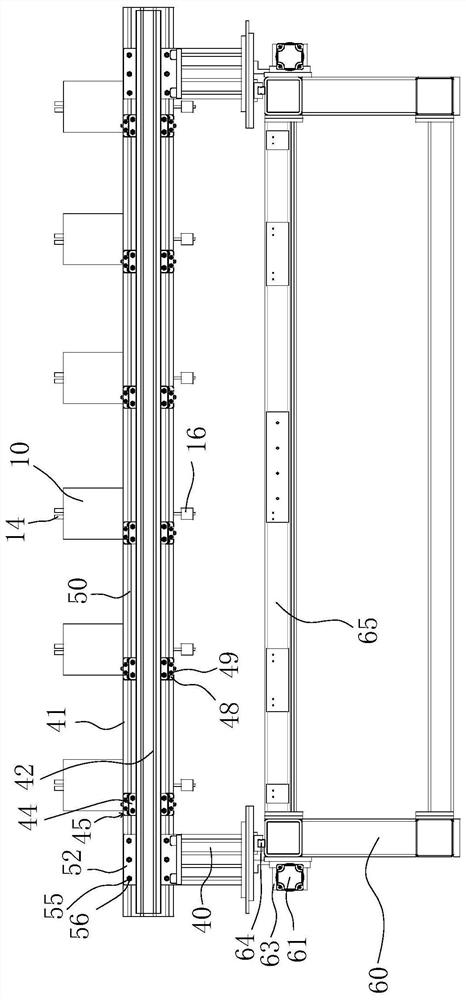

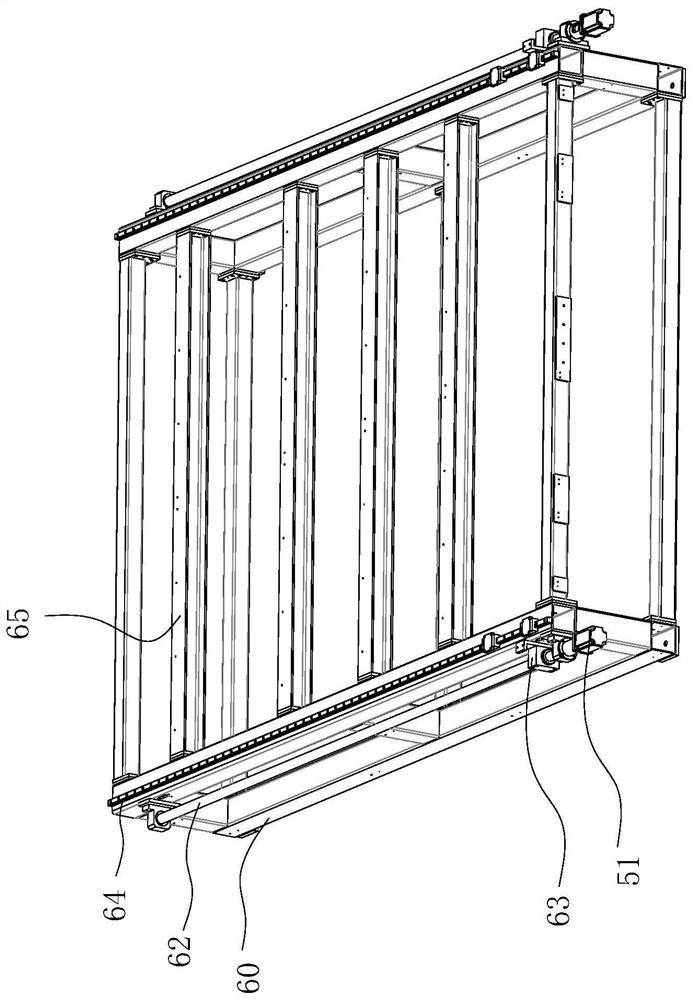

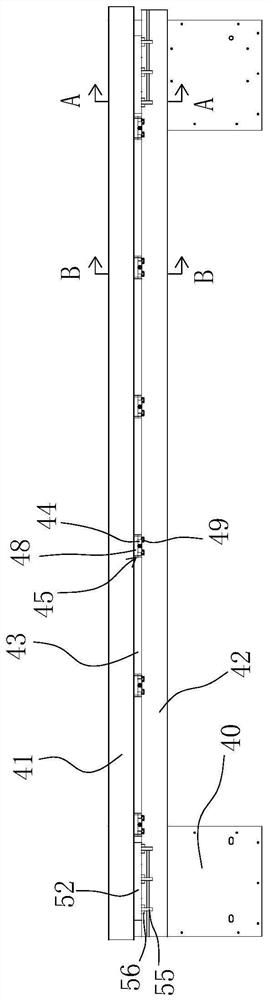

[0031] combine Figure 1-9 As shown, a high-speed inkjet type screen making machine includes a frame 60, two support blocks 40 are slidably connected to the frame 60, and a main beam 41 is erected on the two support blocks 40, and the two support blocks 40 There is a gap between the main beam 41 and the sub-beam 42 to form a sliding passage 43, and several sliding plates 44 are slidably connected in the sliding passage 43, and the sliding plates 44 and the auxiliary The beams 42 are slidably connected, and each sliding plate 44 is supported on the main beam 41 through a detachable clamping mechanism 45. Each sliding plate 44 is provided with an ink tank 10, and the ink tank 10 is provided with an ink tube 11. The inlet and outlet of the ink tube 11 extend out of the two ends of the ink tank 10 respectively, and the ink tank 10 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com