Wire holder, ink-jet printer and ink box

An inkjet printer and terminal block technology, applied in the field of printing, can solve the problems of dry print head channels, affecting printing quality, ink breakage, etc., so as to avoid the operation of cleaning the print head, ensure the printing quality, and avoid the effects of ink breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

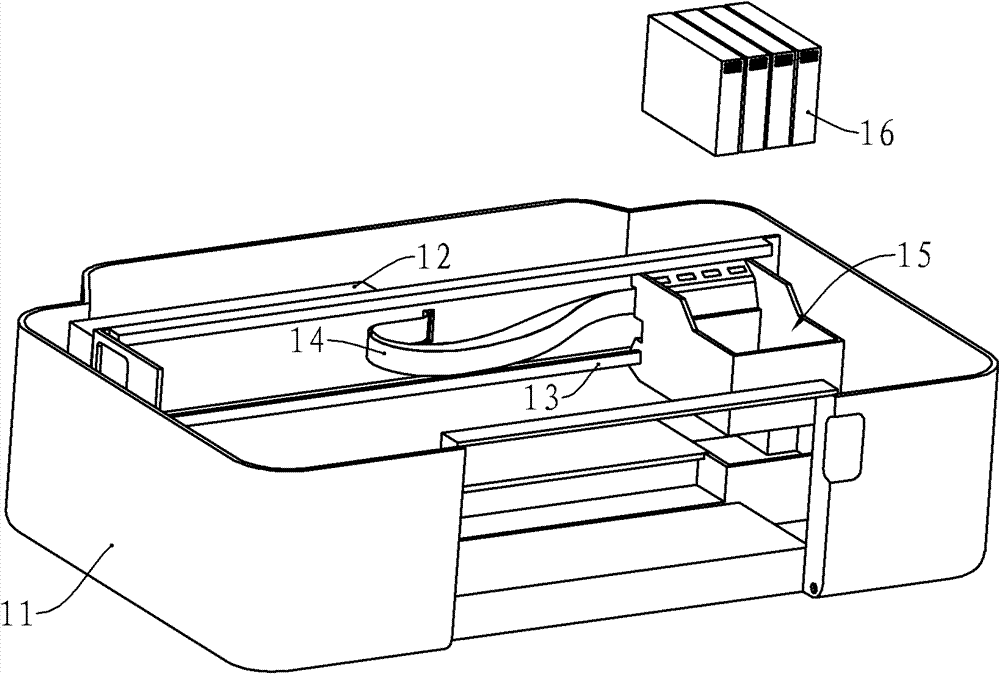

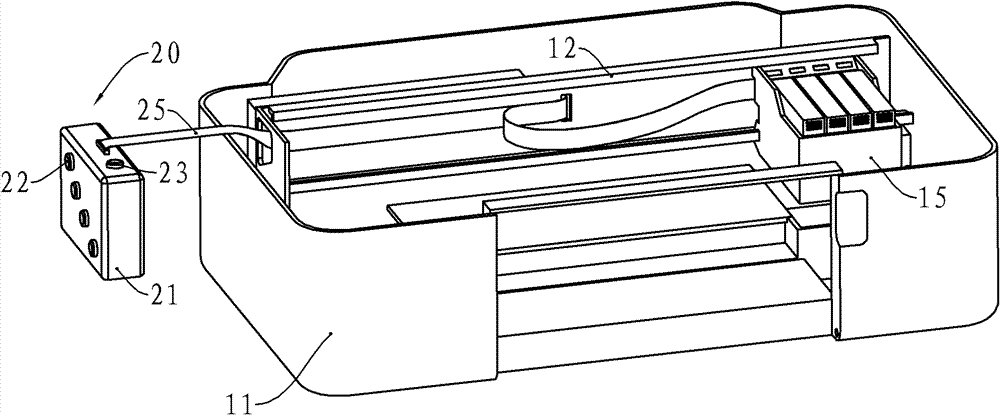

[0039] This embodiment is arranged on an inkjet printer, and the inkjet printer is provided with a printing carriage, and five ink cartridges are detachably installed in the printing carriage, and this embodiment is located outside the casing of the inkjet printer. Moreover, the inkjet printer has a main control circuit board, and the main control circuit board is provided with a communication module. In this embodiment, the main control circuit board is electrically connected to the main control circuit board through a cable.

[0040] see Figure 4 , the present embodiment is roughly in the shape of a cuboid, and has a box body 31, and five chips are arranged in the box body 31, and each chip stores relevant information corresponding to an ink cartridge. A user-friendly wall 32 of the box body 31 is provided with five reset switches 33 , each reset switch 33 corresponds to a chip, and the pressing portion of each reset switch 33 extends out of the wall 32 of the box body 31 ....

no. 2 example

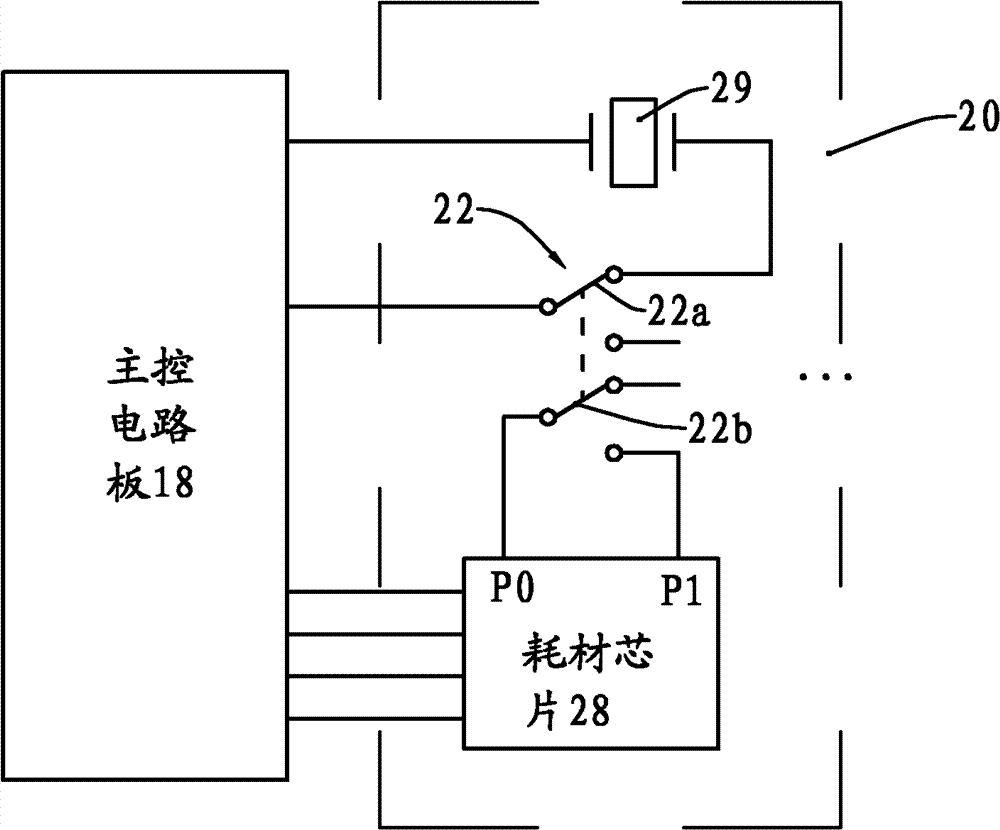

[0052] see Figure 7 , only a chip 61 is set in the terminal block of the present embodiment, and the chip 61 is a micro-controller or an application-specific integrated circuit, and the chip 61 is provided with a memory, which stores the information of five ink cartridges, that is, the chip 61 connects the main control circuit board 19 Output information for five ink cartridges. In addition, the wire socket is provided with five reset switches 62, 63...66, and each reset switch corresponds to an ink cartridge. In addition, the chip 61 is provided with five sets of detection terminals, the first set of detection terminals P10, P11 corresponds to the reset switch 62, the second set of detection terminals P20, P21 corresponds to the reset switch 63, and so on.

[0053] In this embodiment, each reset switch is a double-pole double-throw switch, and the first switch blades 62 a , 63 a . That is, the fixed end corresponding to the switch knife 62a is connected to the main control...

no. 3 example

[0058] see Figure 8 , the box body of the present embodiment is provided with a chip 70, but is provided with five piezoelectric sensors 76...80 and five reset switches 71...75, each piezoelectric sensor corresponds to a reset switch, and each reset switch is Double pole double throw switch. One end of the piezoelectric sensor 76 is connected to a normally closed contact corresponding to a blade 71 a of the reset switch 71 , and a fixed end corresponding to the blade 71 a is connected to the main control circuit board 19 . The other piezoelectric sensors are connected to the reset switch in the same way as the piezoelectric sensor 76 is connected to the reset switch 71 .

[0059] The chip 70 is provided with a memory, stores information corresponding to five ink cartridges, and is provided with five sets of detection terminals, wherein the detection terminals P30 and P31 form a pair of detection terminals, corresponding to the reset switch 71, that is, the switch knife 71b o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com