Drilling machine balance testing device and method for geological drilling

A technology of balance testing and geological drilling, applied in the field of geological drilling, can solve problems such as tilt, side crawler subsidence, and rollover accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

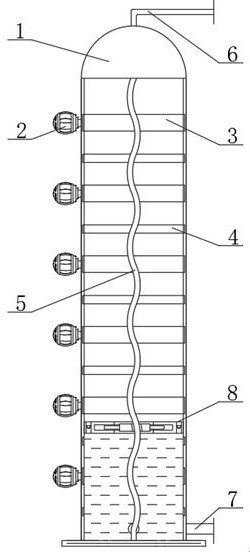

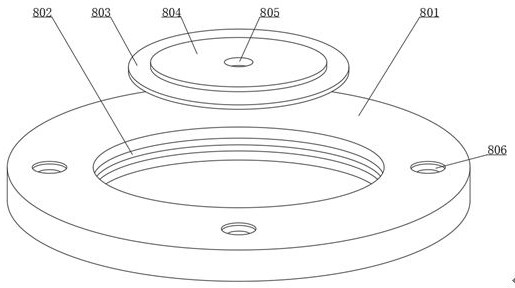

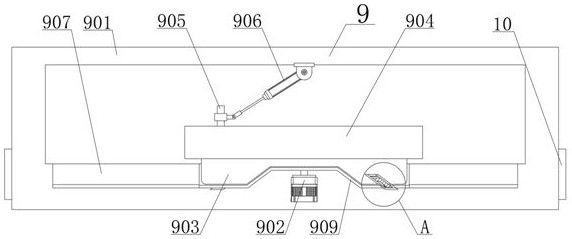

[0033] like Figure 1-8 As shown, a drilling rig balance test device for geological drilling includes drilling equipment and a balance module, the balance module includes a balance measurement device, a balance adjustment device 9 and a compensation device 10, and the balance measurement device is installed above the drilling equipment , used to measure the overall balance of the drilling rig equipment. The balance measuring device is externally connected to a display screen with indicator lights. The balance adjustment device 9 is installed under the drilling rig equipment, and the center of gravity of the balance adjustment device 9 coincides with the center of gravity of the drilling rig equipment. To adjust the balance of the inclined drilling rig equipment, the compensation device 10 is radially installed at the four corners of the balance adjustment device 9. When the balance adjustment device 9 moves to complete the self-balance adjustment work, there is still a small ra...

Embodiment 2

[0047] like Figure 1-8 As shown, a drilling rig balance test device for geological drilling includes drilling equipment and a balance module, the balance module includes a balance measurement device, a balance adjustment device 9 and a compensation device 10, and the balance measurement device is installed above the drilling equipment , used to measure the overall balance of the drilling rig equipment. The compensation device 10 is radially installed at the four corners of the balance adjustment device 9. When the balance adjustment device 9 moves to complete its own balance adjustment work, there is still a small range of inclination. This is because Its volume is too large to accurately achieve the balance purpose, or the balance adjustment device 9 cannot complete the balance work when it is activated to the maximum balance range, and the counterweight body 1003 is pushed outward by activating the pushing device 1002 inside the compensation device 10 at the tilted end , an...

Embodiment 3

[0052] like Figure 1-8 As shown, a drilling rig balance test device for geological drilling includes drilling equipment and a balance module, the balance module includes a balance measurement device, a balance adjustment device 9 and a compensation device 10, and the compensation device 10 is radially installed on the balance The four corners of the adjustment device 9 are used to further compensate the balance of the balance adjustment device 9. When the balance adjustment device 9 moves to complete its own balance adjustment work, there is still a small range of inclination, which is because of its large volume. The purpose of balance cannot be accurately achieved, or the balance work cannot be completed when the balance adjustment device 9 is activated to the maximum balance range. By starting the pushing device 1002 inside the compensation device 10 at the tilted end, the counterweight 1003 is pushed outward, and the center of gravity of the equipment occurs. Offset, now ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com