Clean container structure

A technology for cleaning containers and fixing structures, which is applied in the manufacture of semiconductor/solid-state devices, packaging of vulnerable items, electrical components, etc. It can solve the problems of many dead ends, high cost, difficult manufacturing and assembly, etc., and achieve excellent force transmission methods. , the production cost is reduced, the effect of improving the retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

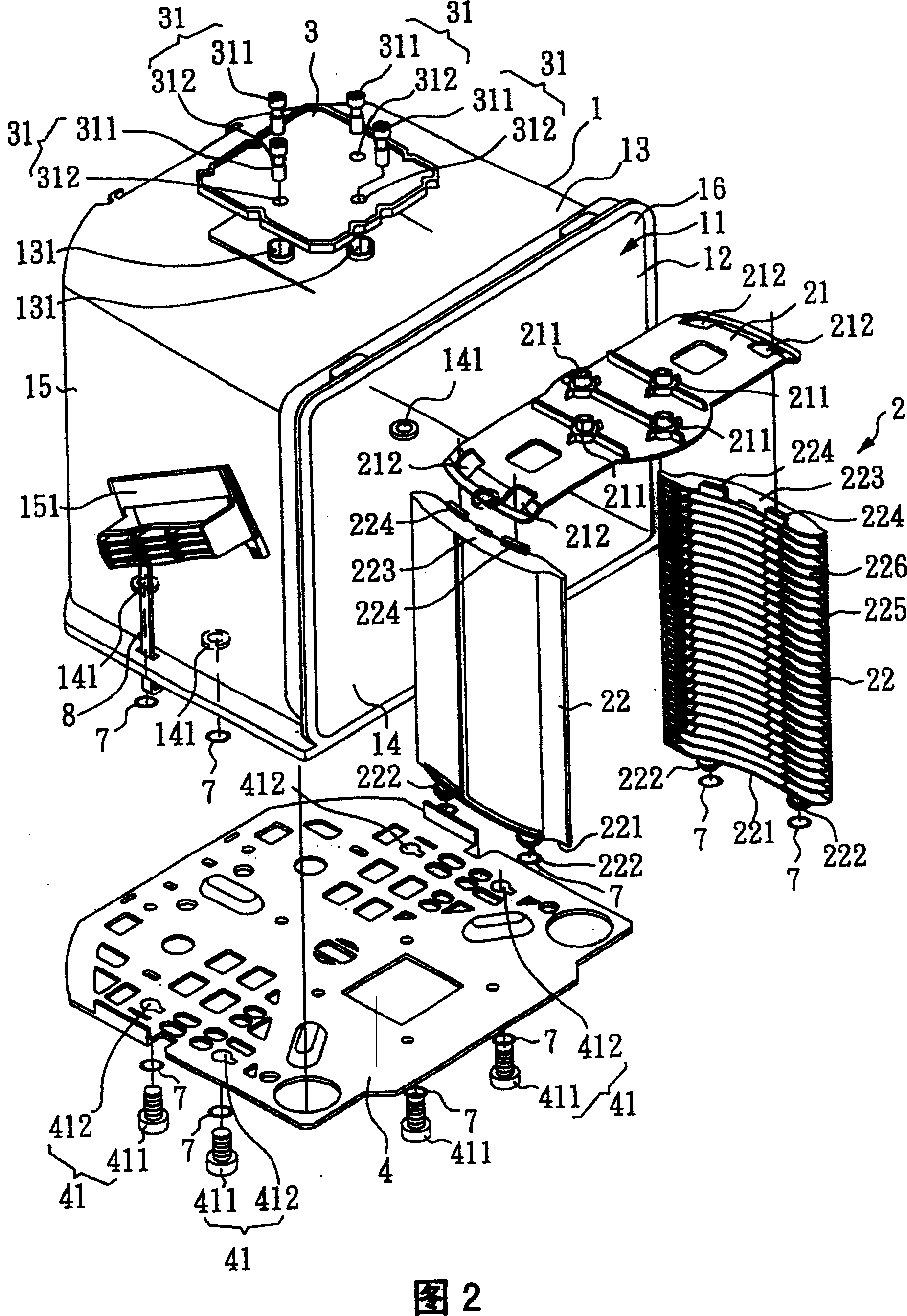

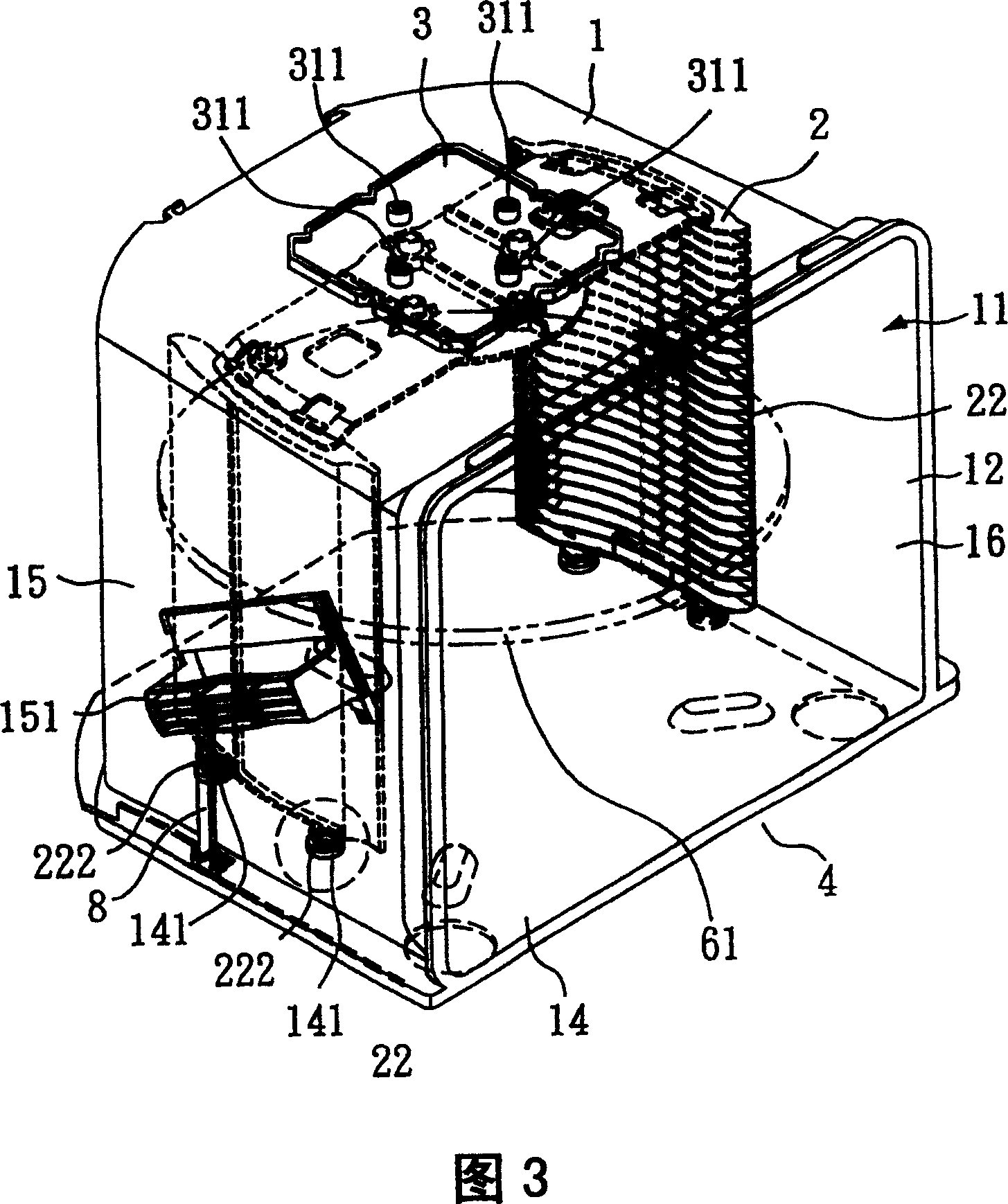

[0032] In order to further understand the technical content of the present invention, two preferred specific embodiments are illustrated as follows.

[0033] Please also refer to FIG. 2 which is an exploded perspective view of the first preferred embodiment of the present invention, FIG. 3 is a perspective combined view of the first preferred embodiment of the present invention, and FIG. 4 is a sectional view of the fixing structure and fixing components of FIG. 3 , which shows a clean container structure, which includes a clean container body 1, a support frame 2, an upper take-off plate 3, and a lower take-off plate 4.

[0034] The clean container body 1 among the accompanying drawings also includes an inner chamber 11, a front opening 12, an upper plate 13, a lower plate 14, a left side plate 15, and a right side plate 16, on the left side plate The outer group of 15 is provided with a left handle 151, is provided with a right handle (not shown) in the opposite group on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com