Patents

Literature

33results about How to "Quarantine entry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

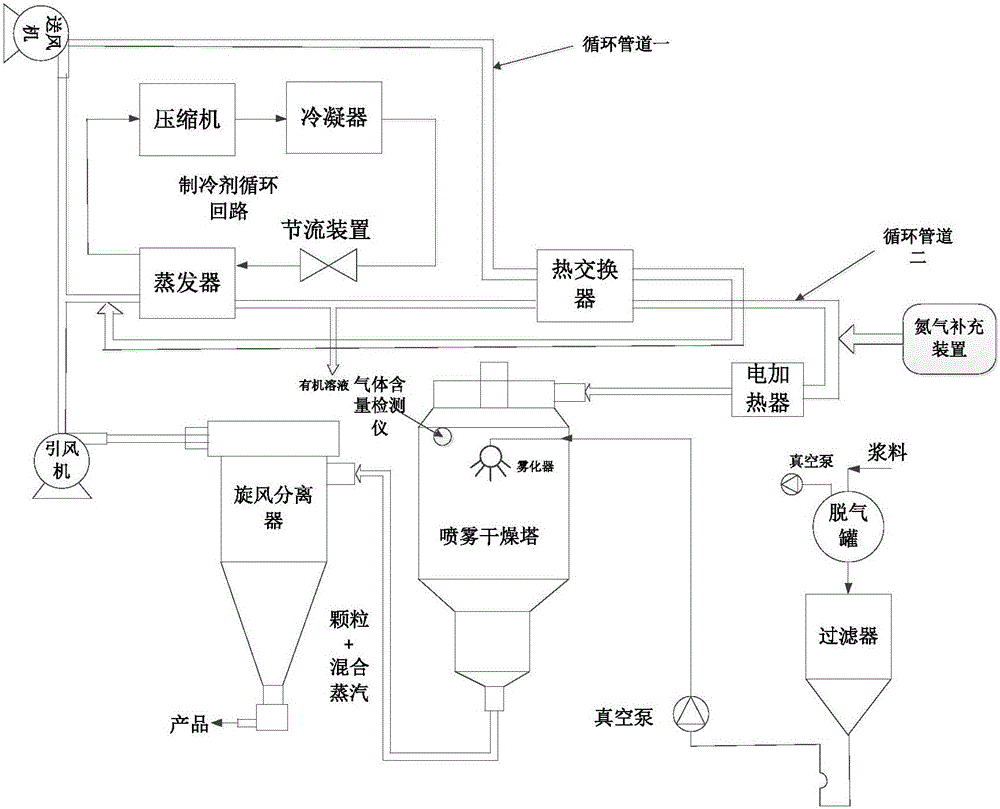

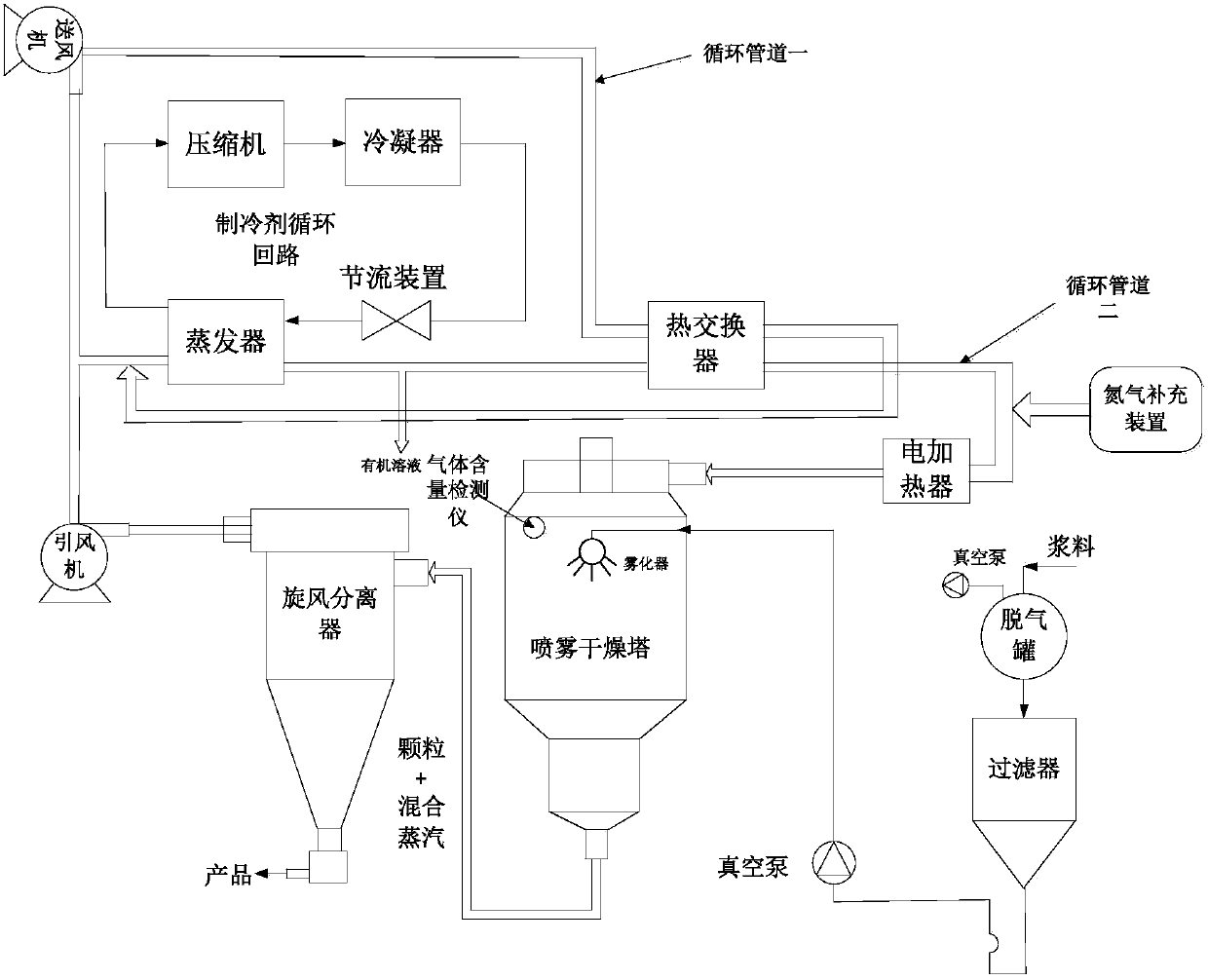

Energy-efficient closed-cycle spray drying system

ActiveCN106166396AQuality assuranceAvoid pollutionMultiple-effect/fractional condensationEvaporator accessoriesNitrogenProduct gas

The invention discloses an energy-efficient closed-cycle spray drying system. The energy-efficient closed-cycle spray drying system comprises a vacuum pump, a degassing tank, a filter, an atomizer, a gas content detector, a spray drying tower, a cyclone separator, an induced draught fan, a refrigerant circulation loop, a heat exchanger, a nitrogen supplementary device, an electric heater, and the like. The energy-efficient closed-cycle spray drying system can be used for recycling and reusing of heat energy of steam discharged from drying towers, and recycling and reusing of organic solutions in the steam at the same time. In the energy-efficient closed-cycle spray drying system, high temperature nitrogen is taken as drying gas, so that product quality is improved effectively, and oxidation of products in production process is avoided.

Owner:常州市海正药化设备有限公司

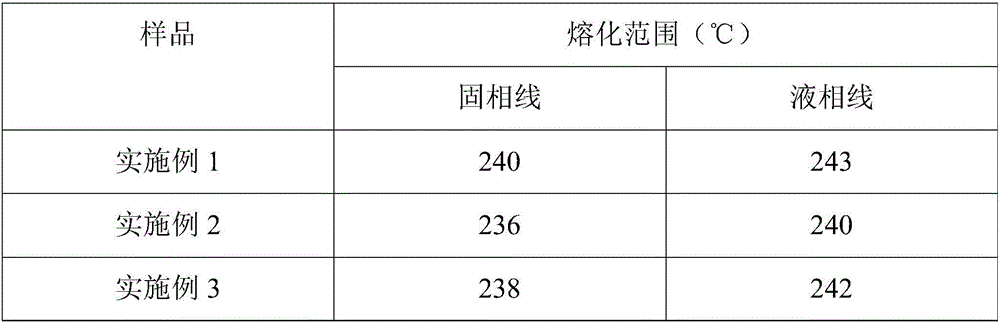

Sn-Zn-Bi-series lead-free welding flux alloy and preparation method thereof

ActiveCN106041353APrevent oxidationProcess stabilityWelding/cutting media/materialsSoldering mediaAlloyBonding strength

The invention provides Sn-Zn-Bi-series lead-free welding flux alloy and a preparation method thereof. The Sn-Zn-Bi-series lead-free welding flux alloy consists of the following elements in percentage by mass: 6-8% of Zn, 1-3% of Bi, 0.2-1% of Ti, 0.02-0.1% of Al, 0.001-0.005% of B and the balance Sn. Compared with the prior art, the Sn-Zn-Bi-series lead-free welding flux alloy has relatively good welding spot bonding strength and also has relatively good resistance to oxidation and wettability.

Owner:TIANJIN UNIV

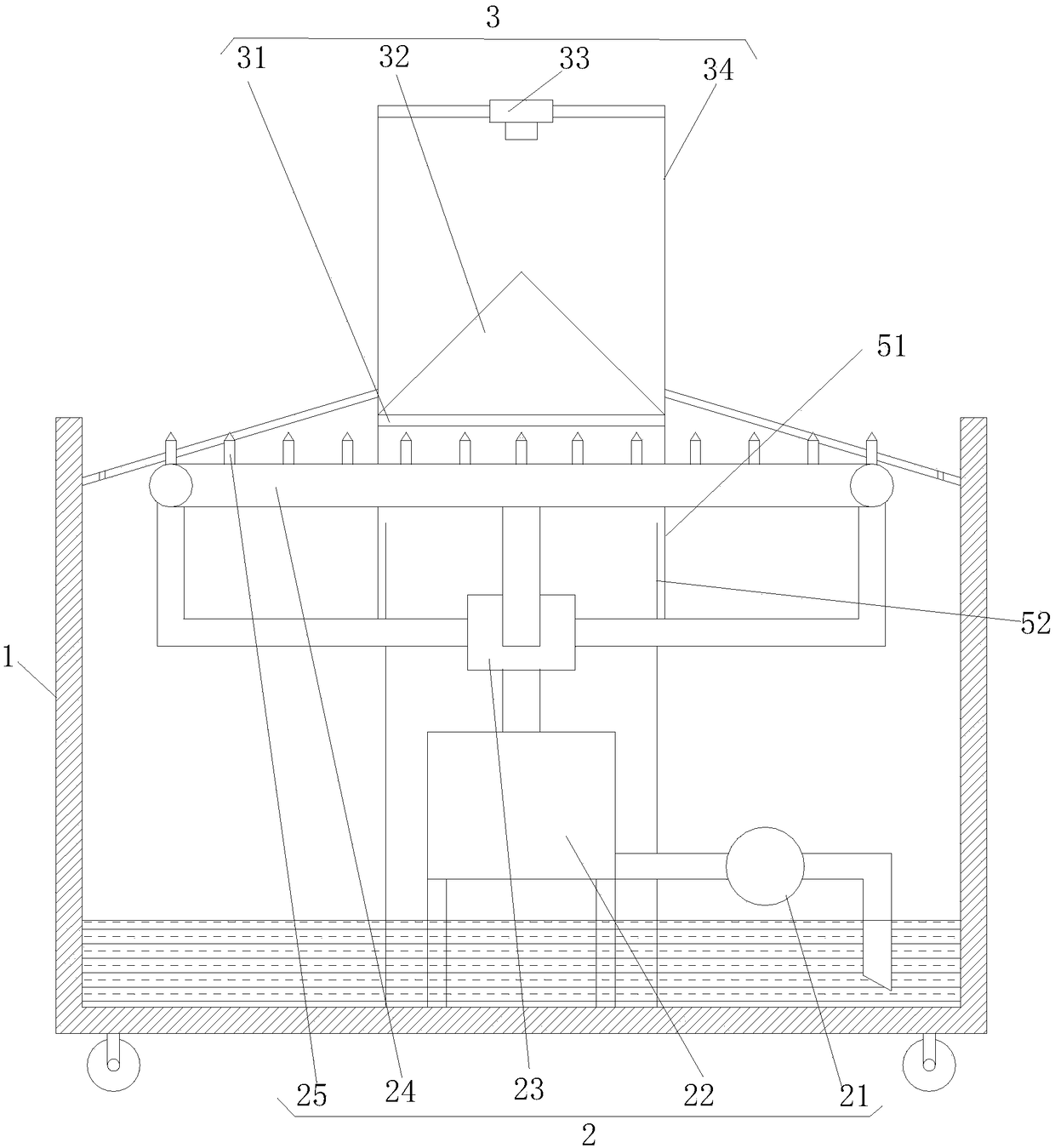

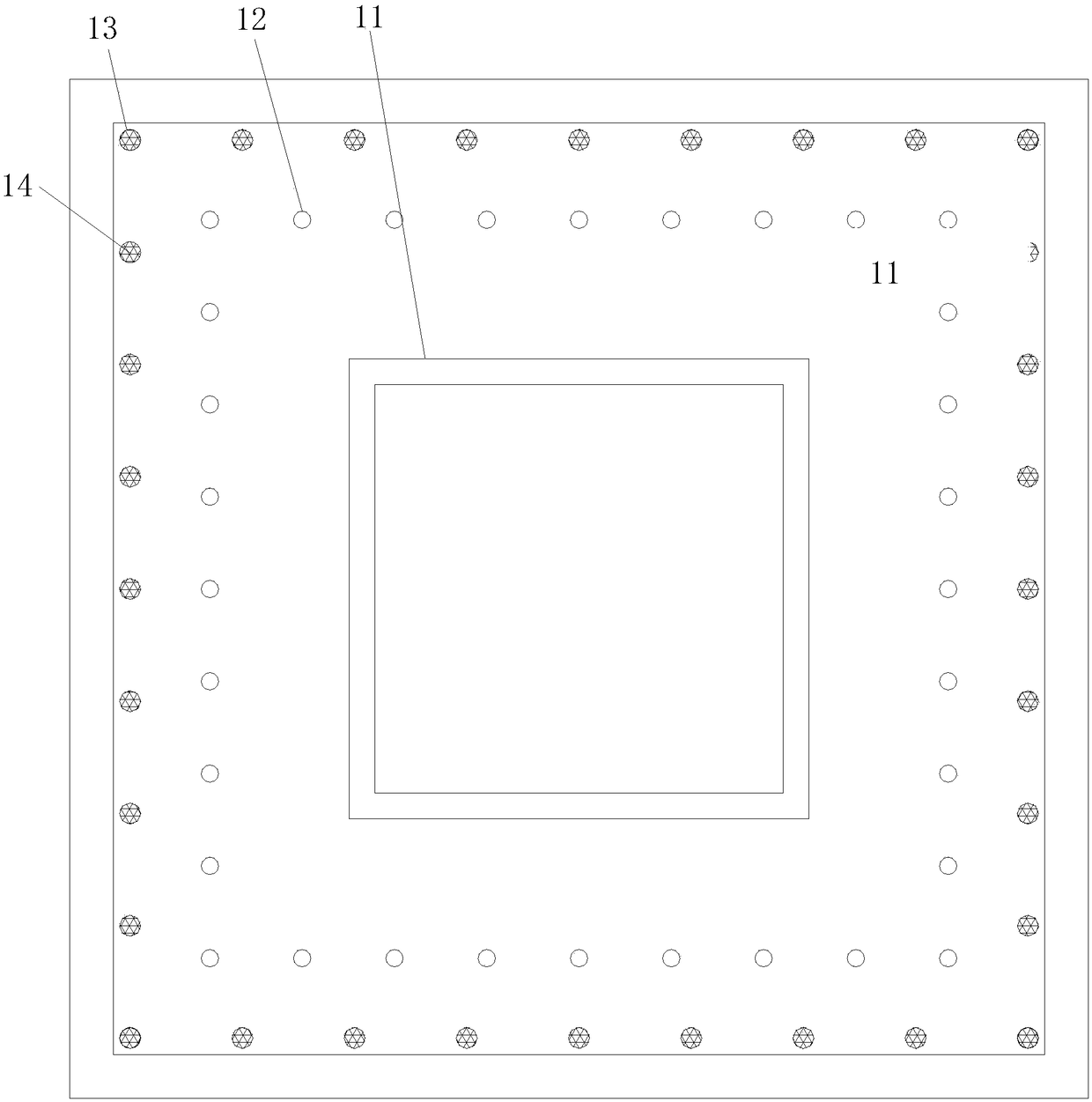

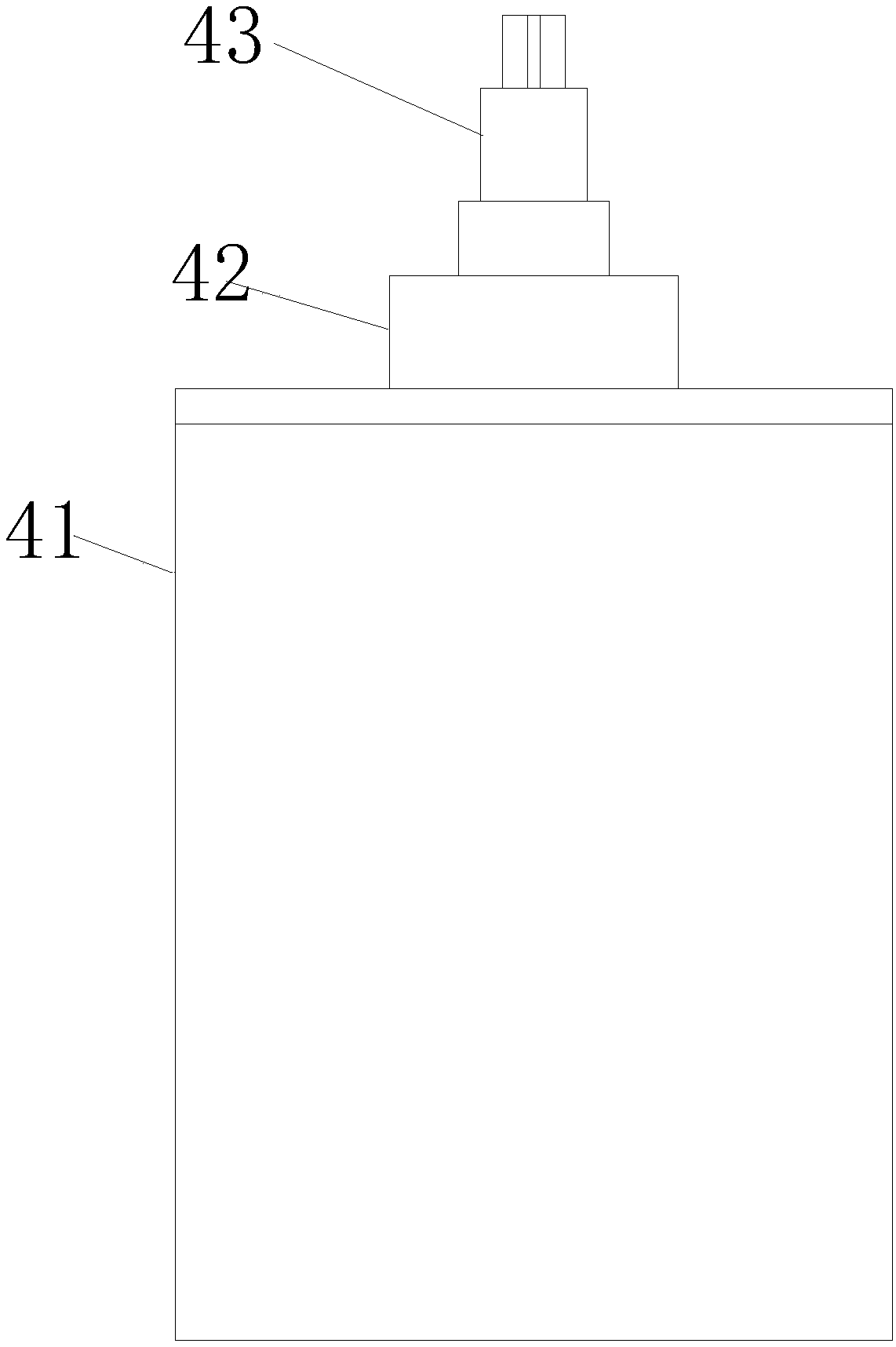

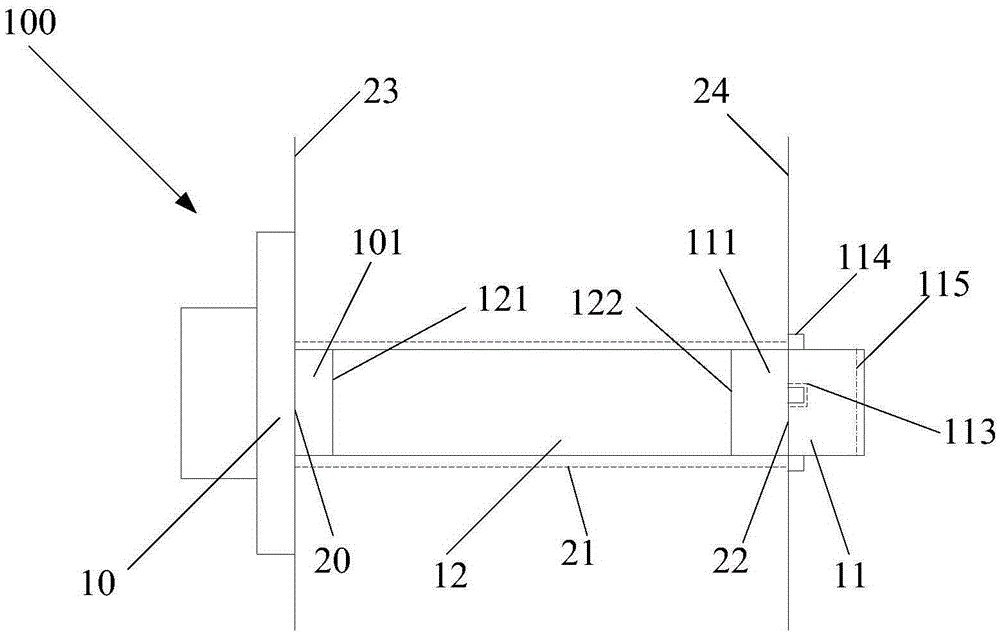

Water curtain projection platform

The present invention discloses a water curtain projection platform. The water curtain projection platform comprises a box body, the box body is internally provided with a water curtain generation module, the middle portion of the box body is provided with a projection module, the projection module is installed at the middle portion of the water curtain generation module, the projection module comprises a support plate, the support plate is provided with a four-prism, a projector projecting downwards is installed above the four-prism, a water-proof cover is installed between the four-prism andthe projector, and a projected image is projected to the water curtain generation module through reflection of the four-prism. Through arrangement of the four-prism, one projector is only used to achieve a holographic image effect to reduce the device manufacturing input and facilitate popularization, a lifting rotation module can drive the projection module to perform motion such as rotation andmovement up and down to allow audiences to obtain more visual experience, a flexible water-proof cover is arranged to effectively isolate water from entering a motor so as to ensure the normal usageof the drive motor.

Owner:WUHU WELLING DIGITAL TECH CO LTD

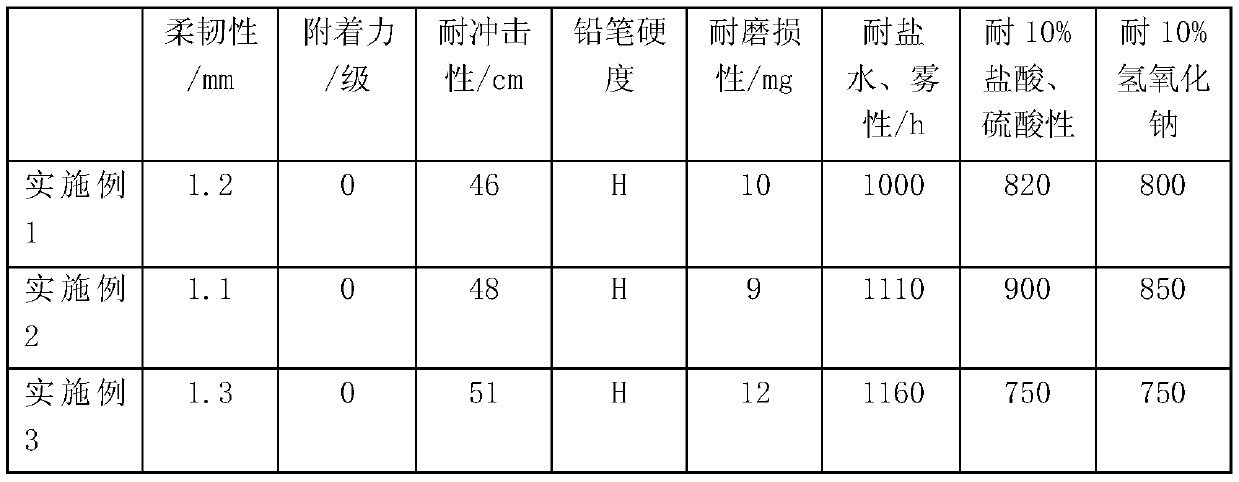

Salt-fog-resistant phosphate modified acrylic waterborne antirust coating for building scaffold

InactiveCN109370349AImprove water resistanceImprove adhesionAnti-corrosive paintsLead ChromatePhosphate

The invention discloses a salt-fog-resistant phosphate modified acrylic waterborne antirust coating for a building scaffold. The salt-fog-resistant phosphate modified acrylic waterborne antirust coating is prepared from the following raw materials in parts by weight: 35-60 parts of salt-fog-resistant phosphate modified acrylic core-shell emulsion, 2-8 parts of cosolvent, 10-15 parts of cobalt naphthenate, 10-15 parts of lead chromate, 5-10 parts of iron laterite, 2-5 parts of strontium chromate, 1-3 parts of rosin, 2-9 parts of ammonium metaborate, 0.5-0.9 part of chlorinated paraffin, 0.3-0.6part of cellulose acetate, 0.2-1.2 parts of dibutyl phthalate, 0.2-1.5 parts of substrate modifier, 0.5-6 parts of auxiliaries and 12-35 parts of deionized water. According to the antirust coating disclosed by the invention, the adhesive force and compactness between a film and a substrate are enhanced, so that water molecules, chloride ions and sodium ions are effectively isolated from enteringbetween substrates, the adhesive force, water resistance and anti-flash rusting property of the film are improved in a wet environment, and the salt-fog-resistant phosphate modified acrylic waterborneantirust coating has good adhesive force, water resistance, salt fog resistance, anti-flash rusting property, acid and alkali resistance and corrosion resistance.

Owner:ANHUI ZULIN NEW MATERIALS

Lead-free paste welding material and preparation method thereof

InactiveCN106475703AReduce contact resistanceImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaMass ratioPositive pressure

The invention proposes a lead-free paste welding material and a preparation method thereof. The lead-free paste welding material is prepared by mixing lead-free solder alloy powder with a flux according to a mass ratio of 10-11: 0.9-1.2; the lead-free solder alloy powder is prepared by the following raw materials: 5-10 wt% of Zn, 0.1-0.2 wt% of Ti, 0.6-2.4 wt% of graphene, and the balance of Sn; and the flux has the following components: 40-50 wt% of adhesive film forming agent, 3-12 wt% of activating agent, 2-8 wt% of thixotropy anti-sinking slipping agent, and the balance of solvent. The preparation method comprises the following steps: the lead-free solder alloy powder and the flux are mixed according to the mass ratio of 10-11: 0.9-1.2; the flux is firstly put in a synthesizer; then, solder powder of the lead-free solder alloy powder is added; the synthesizer is sealed; then, a vacuum system is started for vacuumizing to fill nitrogen to reach positive pressure; a stirring system is started for stirring; the stirring is stopped; and the discharge is performed to obtain the lead-free paste welding material. The lead-free paste welding material is excellent in welding point combination strength; and meanwhile, the flux is better in oxidation resistance without needing to add antioxidant.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

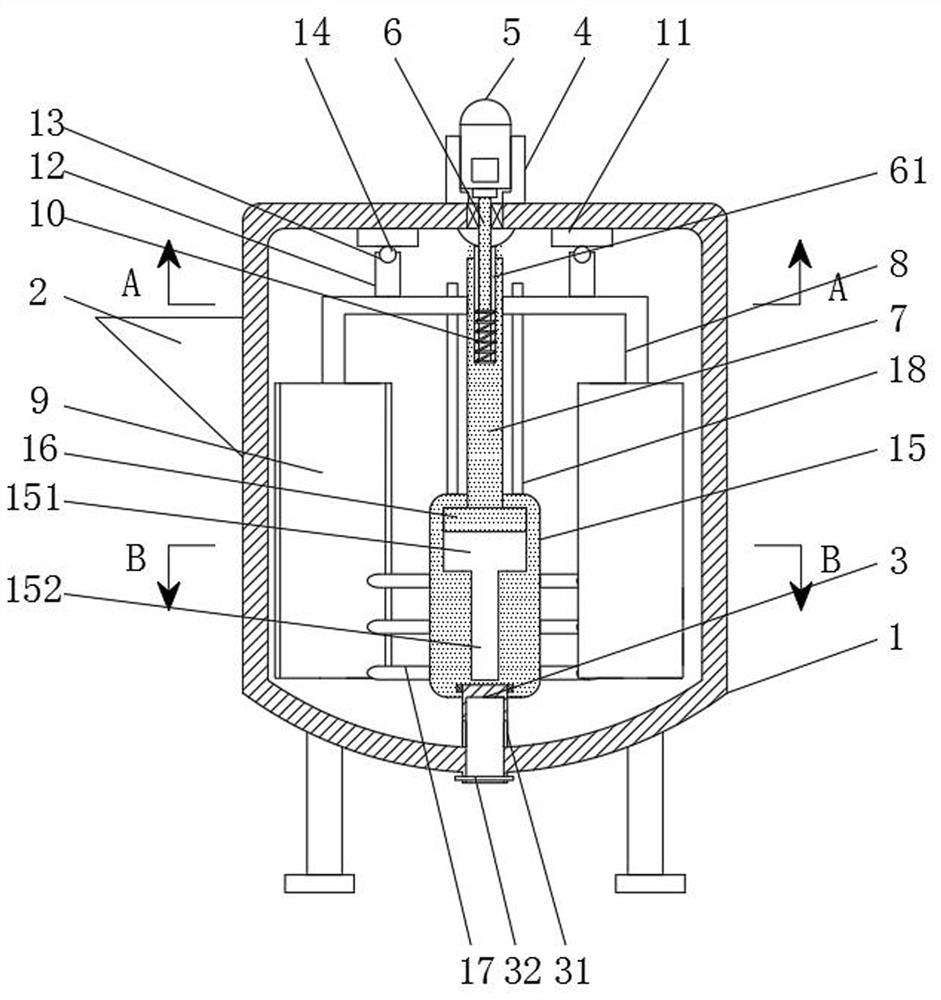

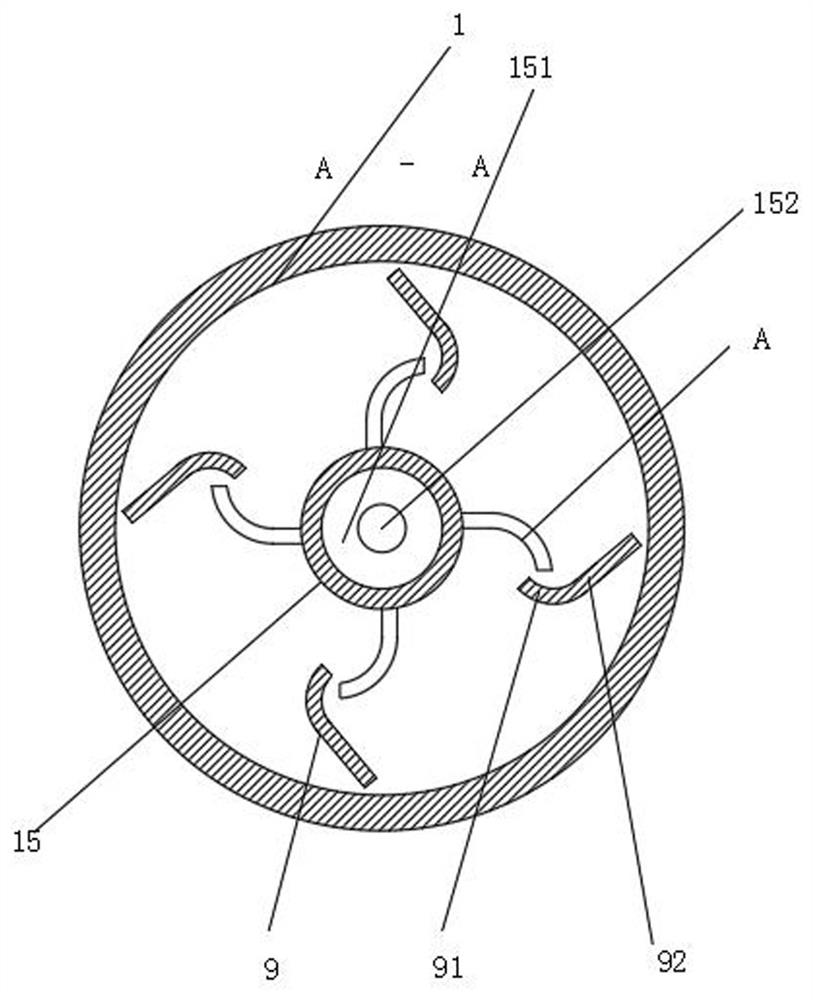

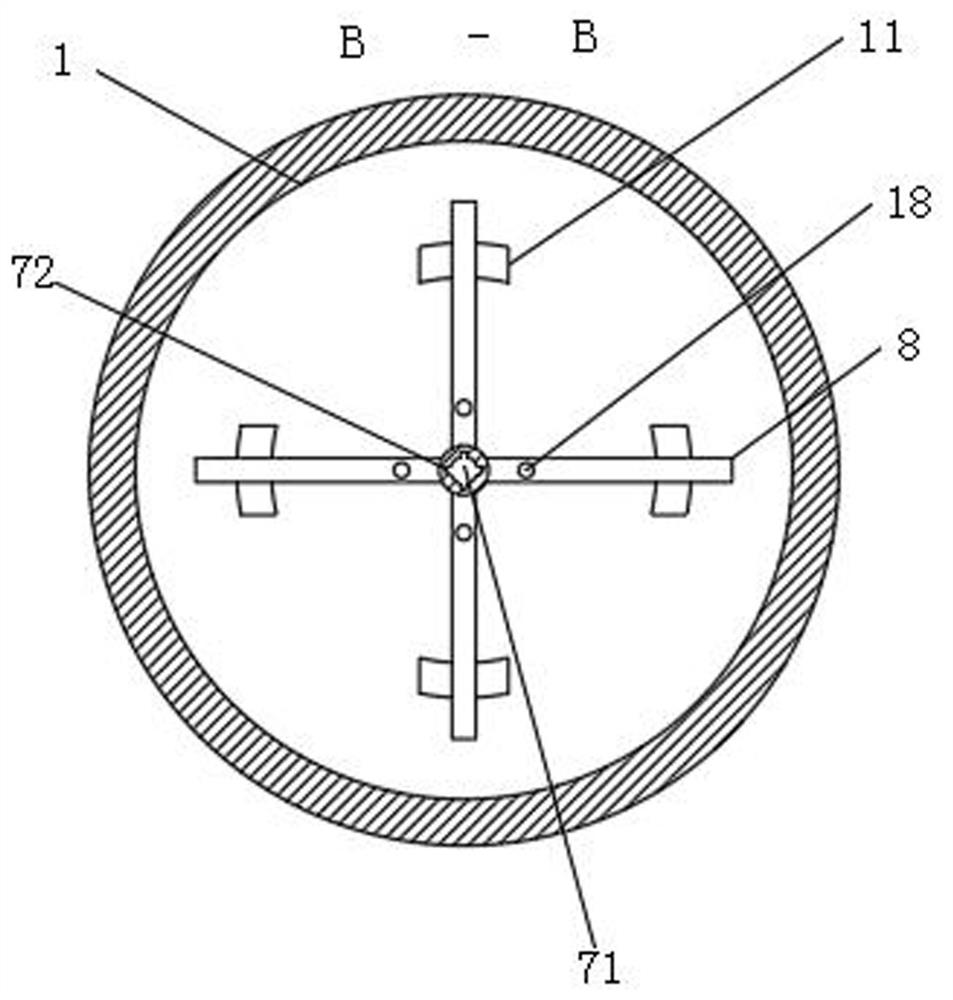

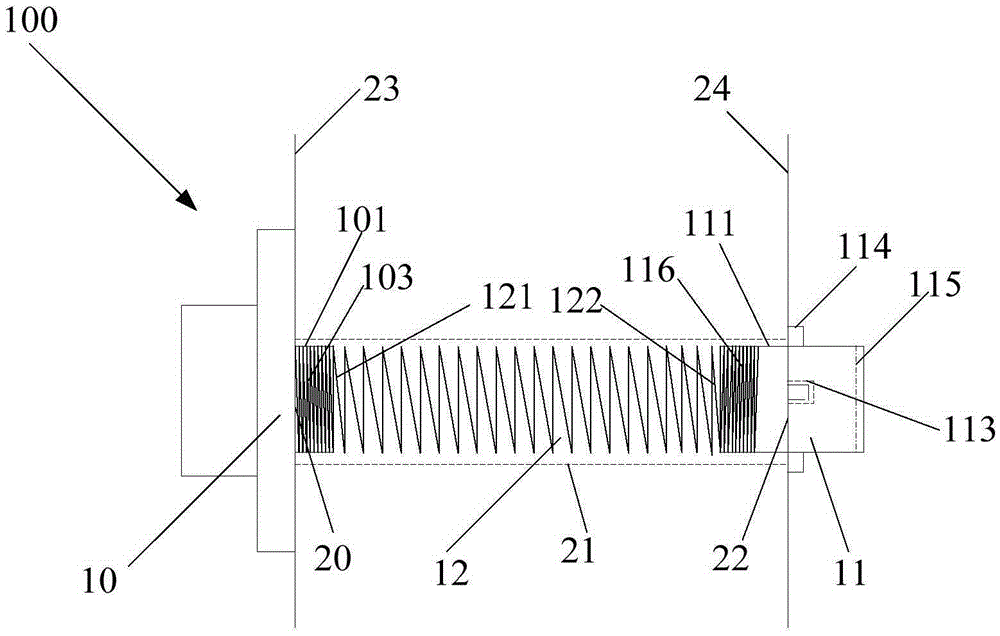

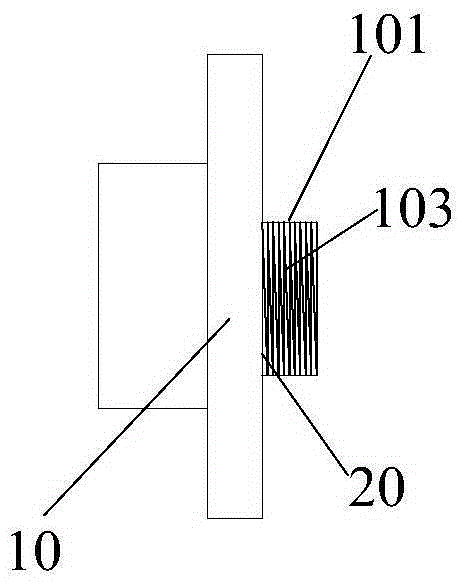

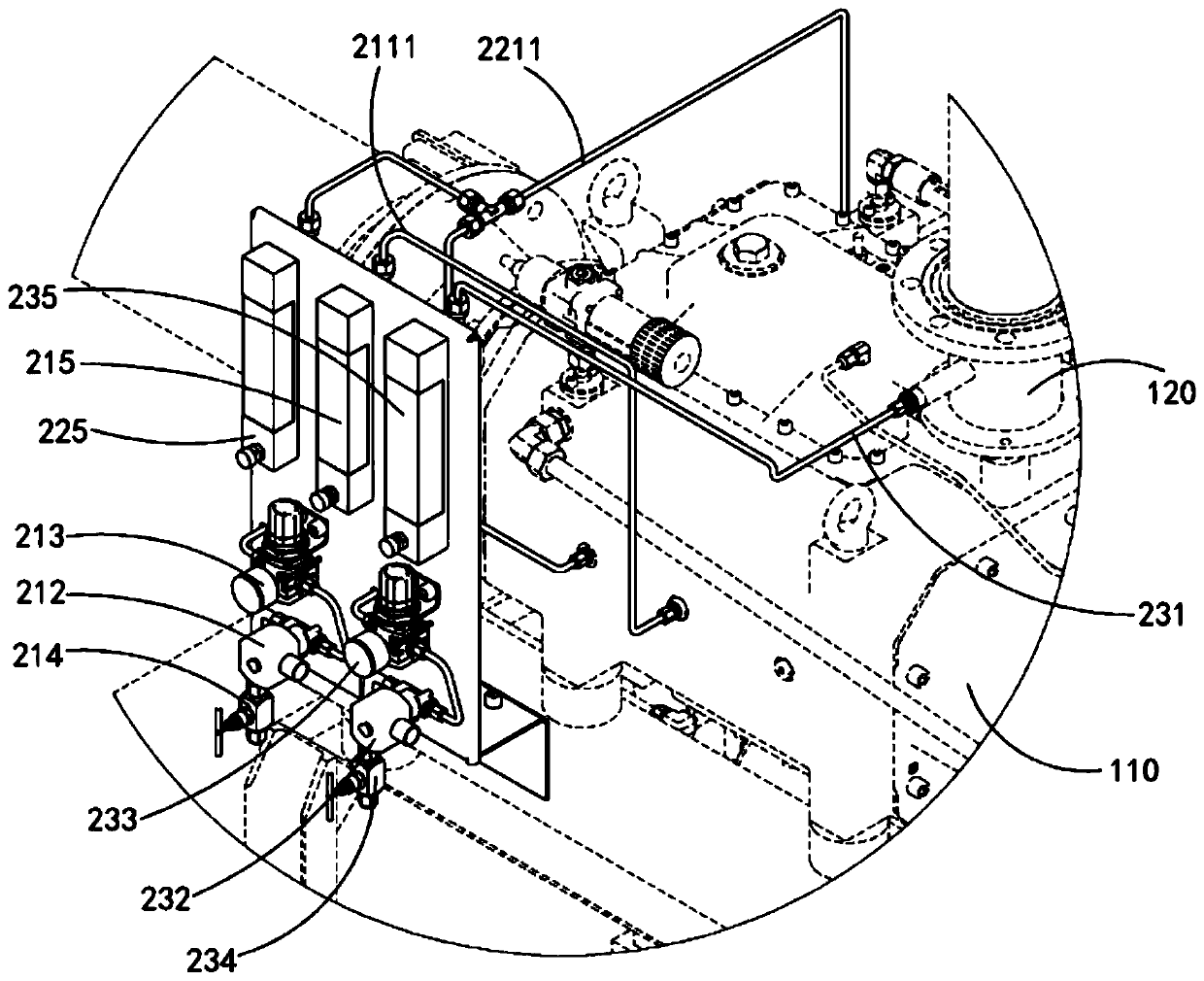

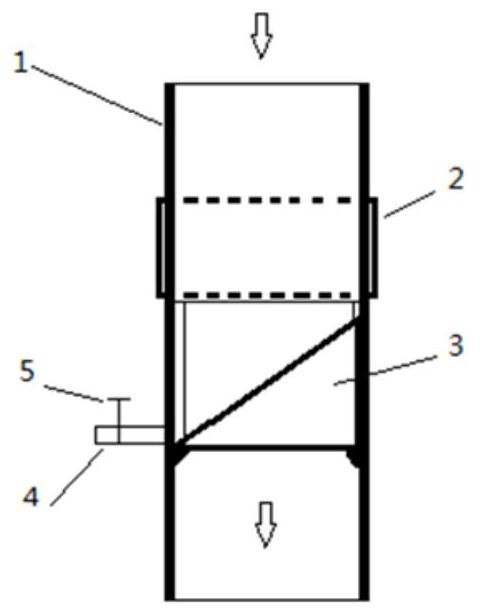

Preparation method of soldering paste for automobile control panel and homogenizing equipment of preparation method

InactiveCN113199171AQuarantine entryPrevent oxidationWelding/cutting media/materialsSoldering mediaOrganic solventActive agent

The invention discloses a preparation method of soldering paste for an automobile control panel and homogenizing equipment of the preparation method. The soldering paste is prepared from tin powder and paste flux in a mass ratio of 85: 15, wherein the tin powder comprises the following components of bismuth alloy solder powder, Sn-Ag-Cu series solder powder, nano titanium particles and graphene, the flux paste comprises the following components of disproportionated rosin, a surfactant, an organic solvent, organic resin powder, zinc chloride powder and an anti-aging agent, and the homogenizing equipment comprises a tank body, a stirring mechanism and a spraying mechanism. According to the method, graphene in a proper proportion is added, and the graphene interacts with solid solution titanium crystals, so that solid solution titanium preferentially reacts with oxygen, a thin and compact oxidation film is instantly formed on the surface of the molten solder, the oxidation film can effectively prevent external oxygen from entering the film, copper in the molten solder can be inhibited from being oxidized, and the oxidation resistance of the solder alloy is remarkably improved.

Owner:江苏博蓝锡威金属科技有限公司

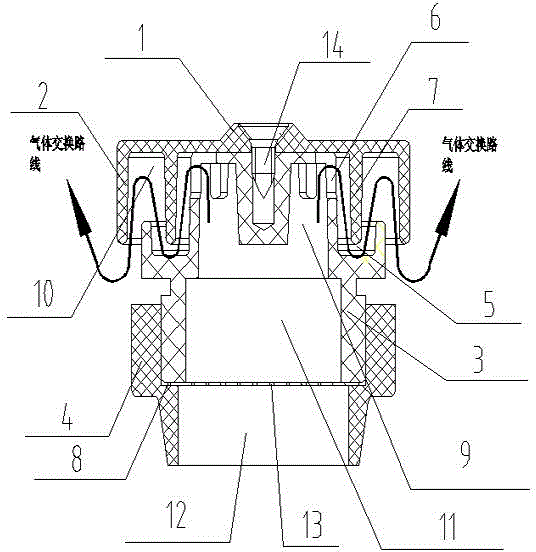

Air exchange air opening external element

ActiveCN105387590AEasy to disassembleImprove securityDucting arrangementsLighting and heating apparatusForeign matterAir exchange

The invention provides an air exchange air opening external element. The air exchange air opening external element comprises an inner air opening part, an outer air opening part and an elastic part. The outer side of the outer air opening part is provided with a clamping groove and a protrusion movably arranged in the clamping groove. The inner side of the outer air opening part is provided with an isolating net. The first end of the inner air opening part is detachably connected with the first end of the elastic part. The first end of the outer air opening part is detachably connected with the second end of the elastic part. The protrusion is used for being reset from the clamping groove to limit the outer air opening part to the outer wall when the outer air opening part sequentially penetrates an inner air outlet opening, a channel in the wall and an outer air outlet and stretches out of the outer wall. According to the air exchange air opening external element, installation personnel can install the outer air opening part from the inner wall side, so that safety of the outer air opening part is improved; and in addition, due to the fact that the outer air opening part is provided with the isolating net, foreign matter such as birds can be effectively prevented from entering the outer air opening part, so that ventilation efficiency is improved.

Owner:ZHEJIANG MELLKIT INTERGRATED CEILING CO LTD

Solder paste special for welding SMD diode

InactiveCN107552996AQuarantine entryPrevent oxidationWelding/cutting media/materialsSoldering mediaMalonic acidGraphene

The invention relates to solder paste special for welding an SMD diode. The solder paste is prepared from, by weight, 10-20 parts of tin-bismuth alloy solder powder, 60-80 parts of Sn-Ag-Cu series solder powder, 2-4 parts of nano titanium particles, 4-6 parts of graphene, 6-10 parts of phenolic alcohol resin, 1-3 parts of malonic acid, 0.5-1.5 parts of lactic acid, 0.5-1.5 parts of benzoic acid, 6-12 parts of n-butyl lactate, 5-15 parts of ethylene glycol, 1.5-2.5 parts of polyoxyethylene ether and 1-3 parts of nitromethane. The solder paste special for welding the SMD diode has the advantagesthat through the components and the proper proportion of the solder paste, the welding quality can be effectively ensured through the solder paste, and thus the solder paste can be applied to electronic devices effectively.

Owner:RUGAO XIAYUAN SCI & TECH ESTABLISH A BUSINESS SERVICES CO LTD

Vegetable greenhouse with ventilation and buffer functions

PendingCN108377815AOvercoming stunted growth and developmentEasy to fixClimate change adaptationGreenhouse cultivationCold airGreenhouse

The invention discloses a vegetable greenhouse with ventilation and buffer functions. The vegetable greenhouse comprises a greenhouse back wall, a greenhouse framework and greenhouse thin film, the greenhouse framework comprises a greenhouse front arc frame and a greenhouse back arc frame, and a ventilation bracket is fixed to the upper end of a greenhouse back wall; the outer side of the ventilation bracket is sleeved with a wind shielding quit, the outer side of the greenhouse front arc frame is fixedly covered with the greenhouse thin film, and the outer side of the greenhouse back arc frame is sleeved with a ventilation quit. According to the vegetable greenhouse, a ventilation structure in a bonnet shape is arranged, cold and warm air go in and go out of the ventilation structure in abuffer manner during the process of letting in fresh air by utilizing the ventilation structure, during the process of letting in the fresh air, the cold air entering into the ventilation structure is firstly mixed with the warm air discharged from the ventilation structure in the ventilation structure, and after the cold air is heated, the heated cold air enters inside the greenhouse, thereby effectively solving the problems that letting in the fresh air causes growth and nutrition problems of the vegetable located at the draught positions.

Owner:甘肃诚坤农业科技有限责任公司

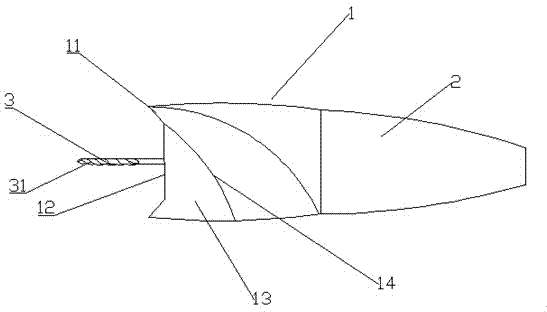

Special-purpose drill for hole drilling

InactiveCN104842418AEffective chip removalReduce the probability of reimbursementWood turning toolsWood boring toolsOil drillingDepth limit

The invention discloses a special-purpose drill for hole drilling. The special-purpose drill for hole drilling comprises a drill body and a drill stock, wherein the drill body is fixedly connected with the drill stock; the drill body comprises a depth limiting device and a drill tip arranged in the depth limiting device; the drill tip is provided with a spiral chip groove; the whole drill stock is a cylindrical drill stock; the diameter of the cylindrical drill stock is sequentially reduced gradually from the other end which is far away from the drill body to the tail end of the drill stock so that the frustum-shaped drill stock is formed; the depth limiting device has a thickness limiting structure mainly; a central axis of the depth limiting device serves an axis of the drill tip; and the drill tip penetrates in the whole drill. The special-purpose drill for hole drilling has the advantages that the special-purpose drill for hole drilling comprises the depth limiting device and the drill tip arranged in the depth limiting device, the drill tip is provided with the spiral chip groove, a helical angle of the chip groove is 15-30 degrees, chips can be removed effectively, the probability of scrappage of products is reduced, by the depth limiting device, a required hole drilling depth can be confirmed effectively, wood cannot be pierced thoroughly, and the work efficiency and the work accuracy are improved.

Owner:启东市吕四科技创业中心有限公司

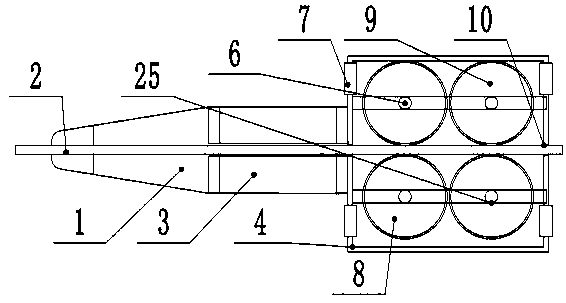

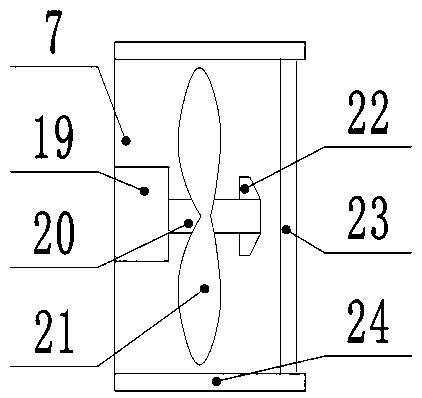

Welding wire impurity-removal mechanism for welding

InactiveCN109719364AImprove stabilityAvoid scratchesSolder feeding devicesSoldering auxillary devicesSuction forceEngineering

The invention relates to the field of welding, in particular to a welding wire impurity-removal mechanism for welding. The welding wire impurity-removal mechanism for welding comprises a welding gun gun-head, a welding wire, a welding gun impurity-removal cabin and a welding wire reshaping impurity-removal part, wherein an impurity-removal cabin front supporting rod and an impurity-removal cabin rear supporting rod are separately arranged at the two sides inside the welding gun impurity-removal cabin; the inner structure of the welding wire reshaping impurity-removal part is symmetrical vertically; charge holes are formed in the middle parts of two ends of the welding wire reshaping impurity-removal part; a rotary rod is fixedly mounted above the welding wire reshaping impurity-removal part; and a fan part is arranged at the upper end of the welding wire reshaping impurity-removal part. Threads at the tail end of the rotary shaft are fixedly equipped with limiting screws which can limit fan blades, so that dropping during high-speed rotation is prevented; and a filter screen which is a nylon wire screen is arranged at the right end of the fan bracket, so that dust in air can be effectively prevented from entering; and impurities on the surface of the front roller and the surface of the rear roller can be discharged through suction force of a fan.

Owner:QINGDAO YIDIAN PLASTIC WELDING EQUIP

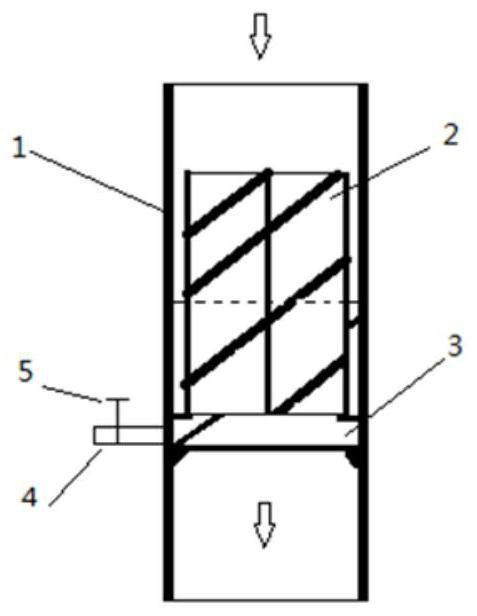

Fixed device for soil pH value detecting instrument

InactiveCN103630673AEffectively isolate entryQuarantine entryEarth material testingMeasurement precisionMetal

The invention discloses a fixed device for soil pH value detecting instrument. The fixed device is in a cylinder shape, wherein the cylinder shape comprises a metal layer, a filter membrane layer and a thin film layer from outside to inside; the metal layer is in a porous structure, and the diameters of holes are 2mm; the filter membrane layer is in a net structure, and the side lengths of grids are 0.25m; the thin film layer is in the net structure, and the side lengths of grids are 0.03mm. The fixed device comprises a solar panel and an electric energy controller, wherein the solar panel forms 45-60-degree angle with the top surface of the fixed device, and the electric energy controller is connected with the solar panel and the pH value detecting instrument; a fixed bracket is fixed on the top surface of the fixed device, and a fixed tube of the pH value detecting instrument is fixed on the fixed bracket. Compared with the prior art, by arranging a three-layer structure, the soil and other substances are effectively prevented from entering a detection region of the detecting instrument, so that not only can the detecting instrument be protected, but also the measuring accuracy can be improved; the fixed device has great popularization significance.

Owner:天津滨海宏旺科技有限公司

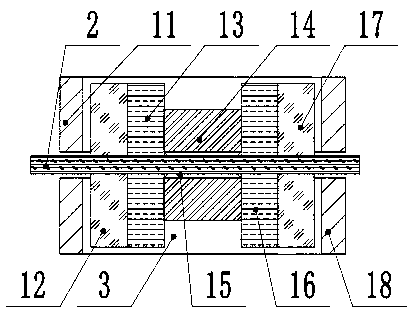

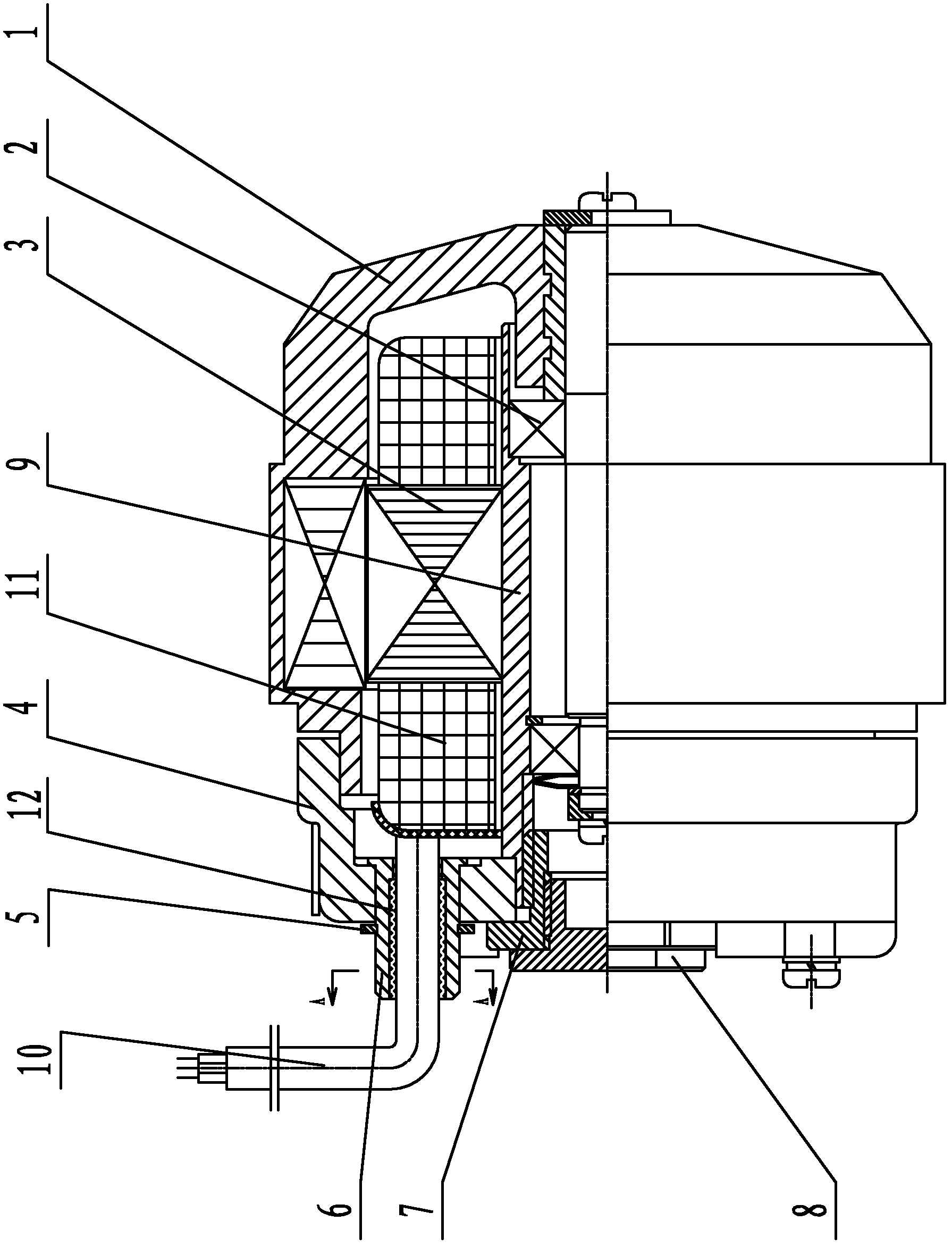

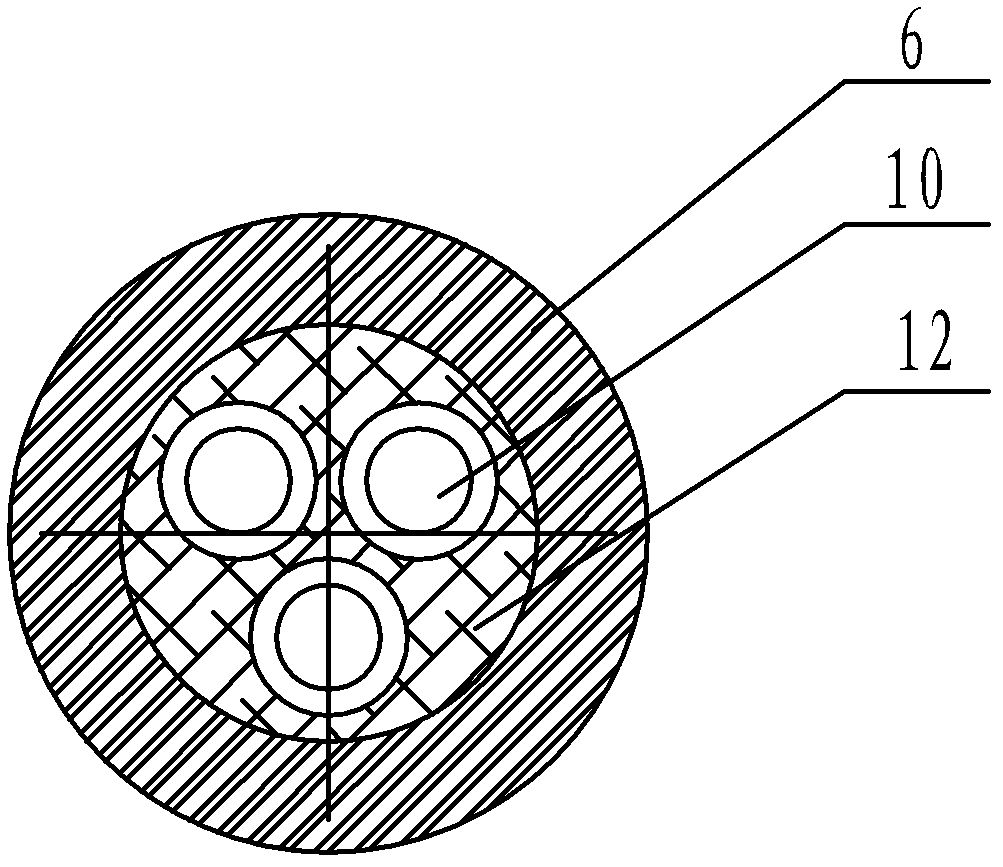

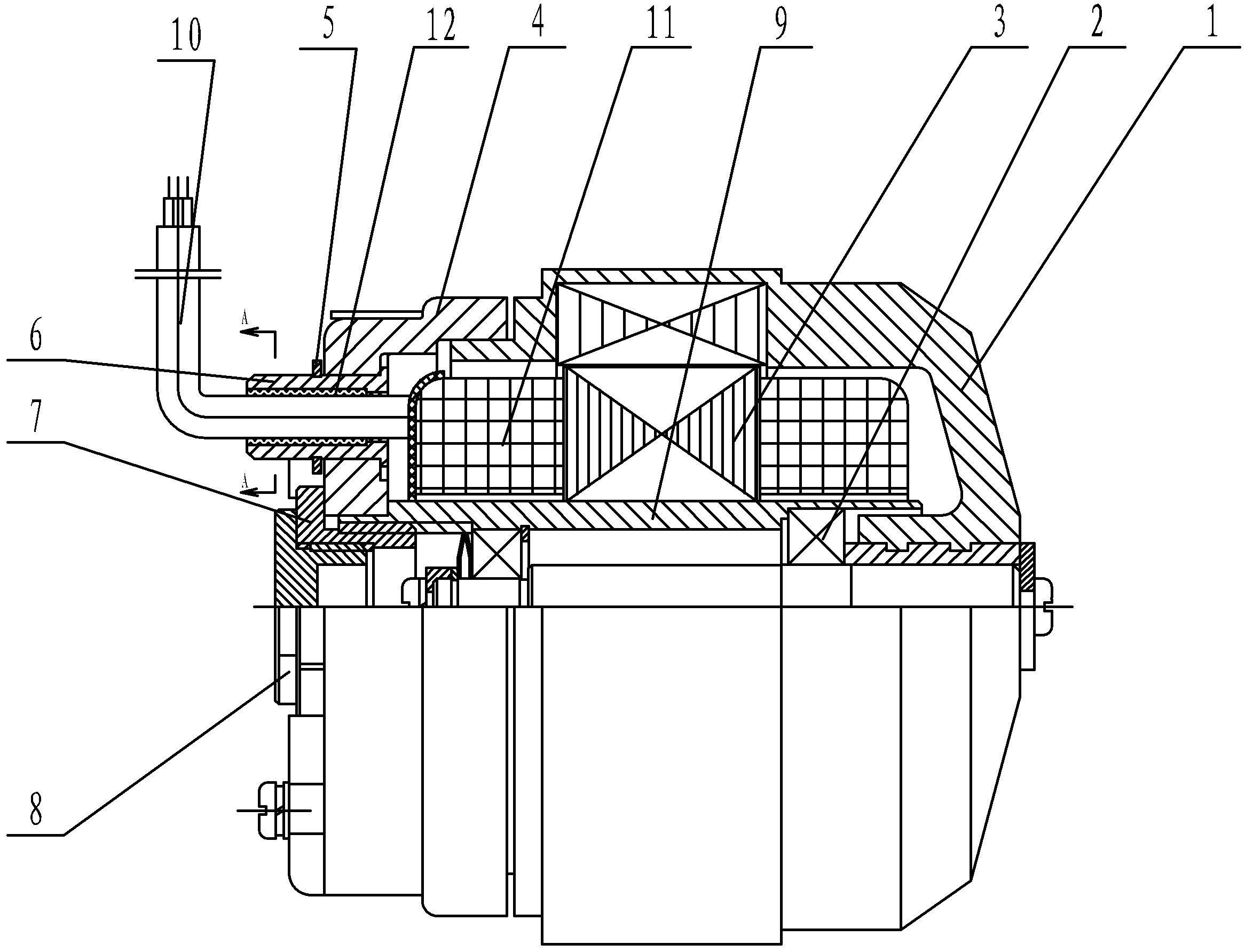

Explosion-proof three-phase asynchronous outer rotor motor

InactiveCN102255455AQuarantine entryPlay an isolation effectAsynchronous induction motorsSupports/enclosures/casingsIsolation effectEpoxy

The invention relates to an explosion-proof three-phase asynchronous outer rotor motor. The motor comprises a motor stator and a stator coil which are arranged on a main shaft. An outgoing line is connected to the stator coil. A bearing is arranged in the main shaft. A motor rotor is arranged on the main shaft in a rotating way by the bearing. A fastening bolt is screwed on the end part of the main shaft. A sealing cap is arranged on the fastening bolt. An end cover is fixedly arranged on the main shaft by the fastening bolt. A connecting sleeve is fixedly arranged on the end cover. The outgoing line is inserted into the connecting sleeve. An explosion-proof filler is filled between the outer wall of the outgoing line and the inner wall of the connecting sleeve. The outgoing part of the motor is provided with the connecting sleeve and epoxy resin is filled in a gap after the outgoing line is inserted to effectively isolate explosive gases; and certain assembly precision and certain axial jointing lengths are adopted for all jointing surfaces to effectively achieve an isolation effect.

Owner:WUXI XISHAN SPECIAL FAN

Preparation method of soldering paste special for patch diode welding

InactiveCN107695567AQuarantine entryPrevent oxidationWelding/cutting media/materialsSoldering mediaMalonic acidBismuth

The invention relates to a preparation method of a soldering paste special for patch diode welding. The soldering paste comprises the following components of, by weight, 10-20 parts of tin-bismuth alloy solder powder, 60-80 parts of Sn-Ag-Cu series solder powder, 2-4 parts of nano titanium particles, 4-6 parts of graphene, 6-10 parts of phenolic resin, 1-3 parts of malonic acid, 0.5-1.5 parts of lactic acid, 0.5-1.5 parts of benzoic acid, 6 to 12 parts of n-butyl lactate, 5-15 parts of ethylene glycol, 1.5-2.5 parts of alcohol-polyoxyethylene ether and 1-3 parts of nitromethane. The preparation method of the soldering paste special for patch diode welding has the advantages that by means of the components of the method and the appropriate proportion, the soldering paste can effectively guarantee the welding quality and then can be effectively applied to electronic components.

Owner:RUGAO XIAYUAN SCI & TECH ESTABLISH A BUSINESS SERVICES CO LTD

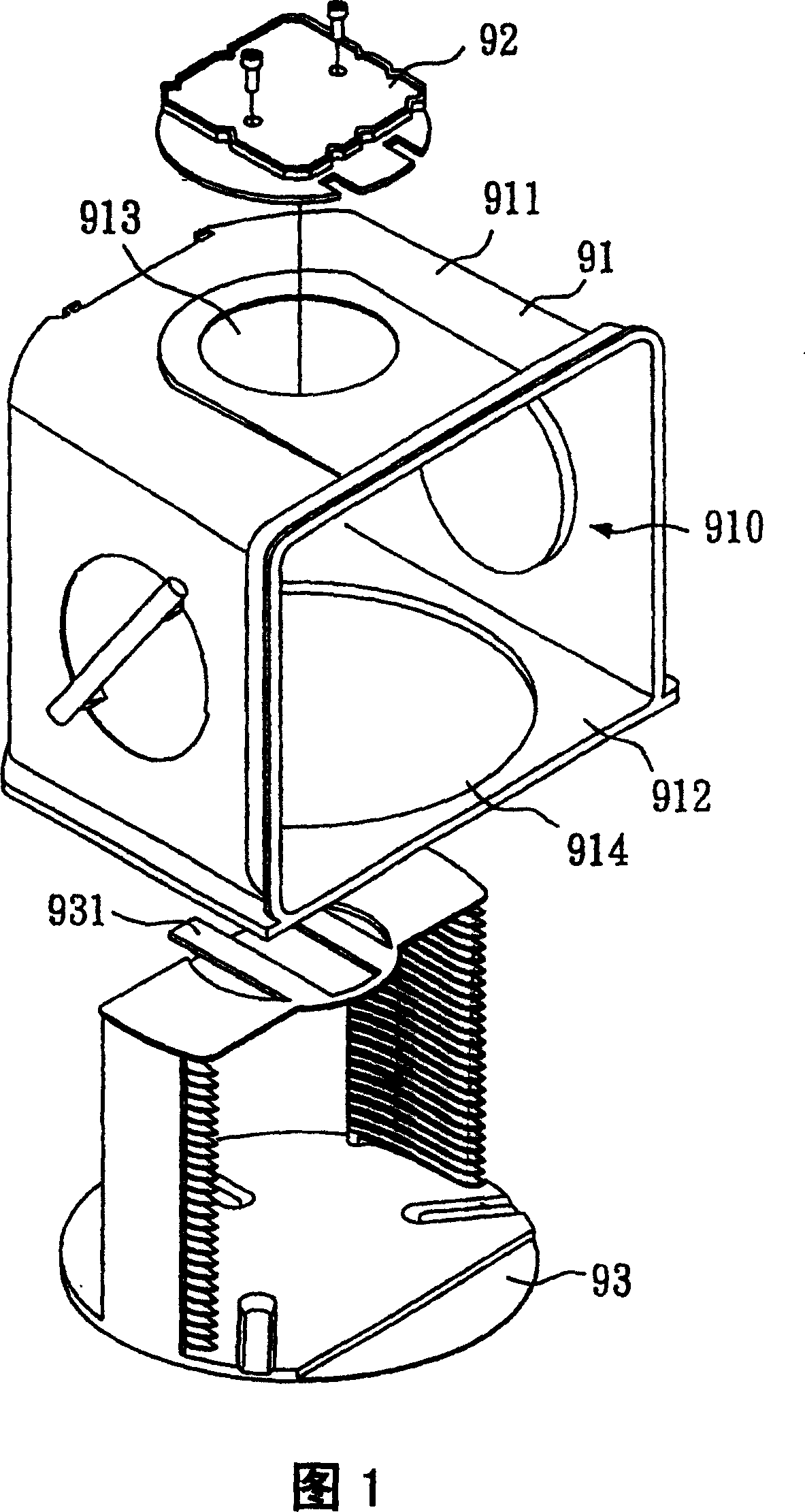

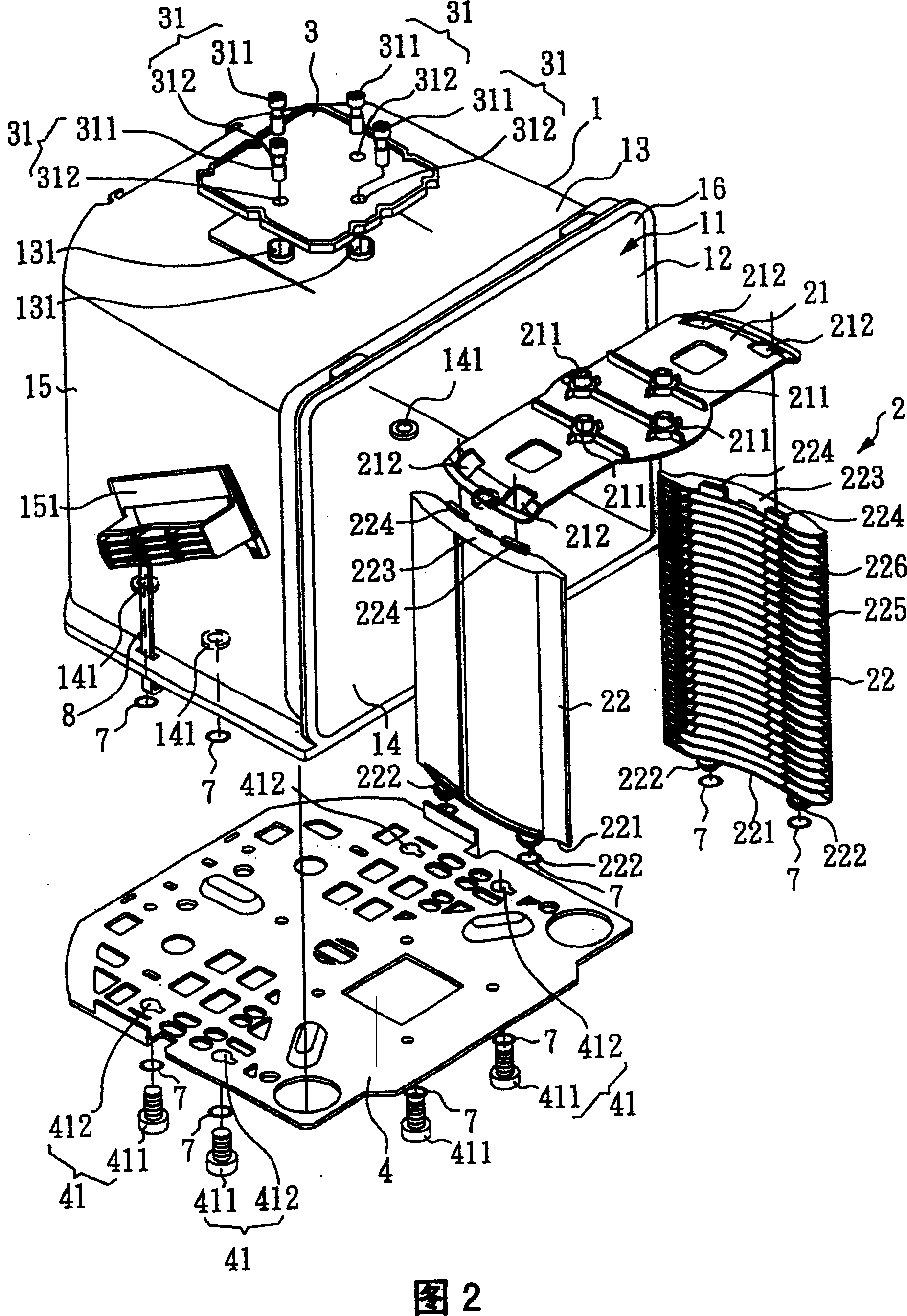

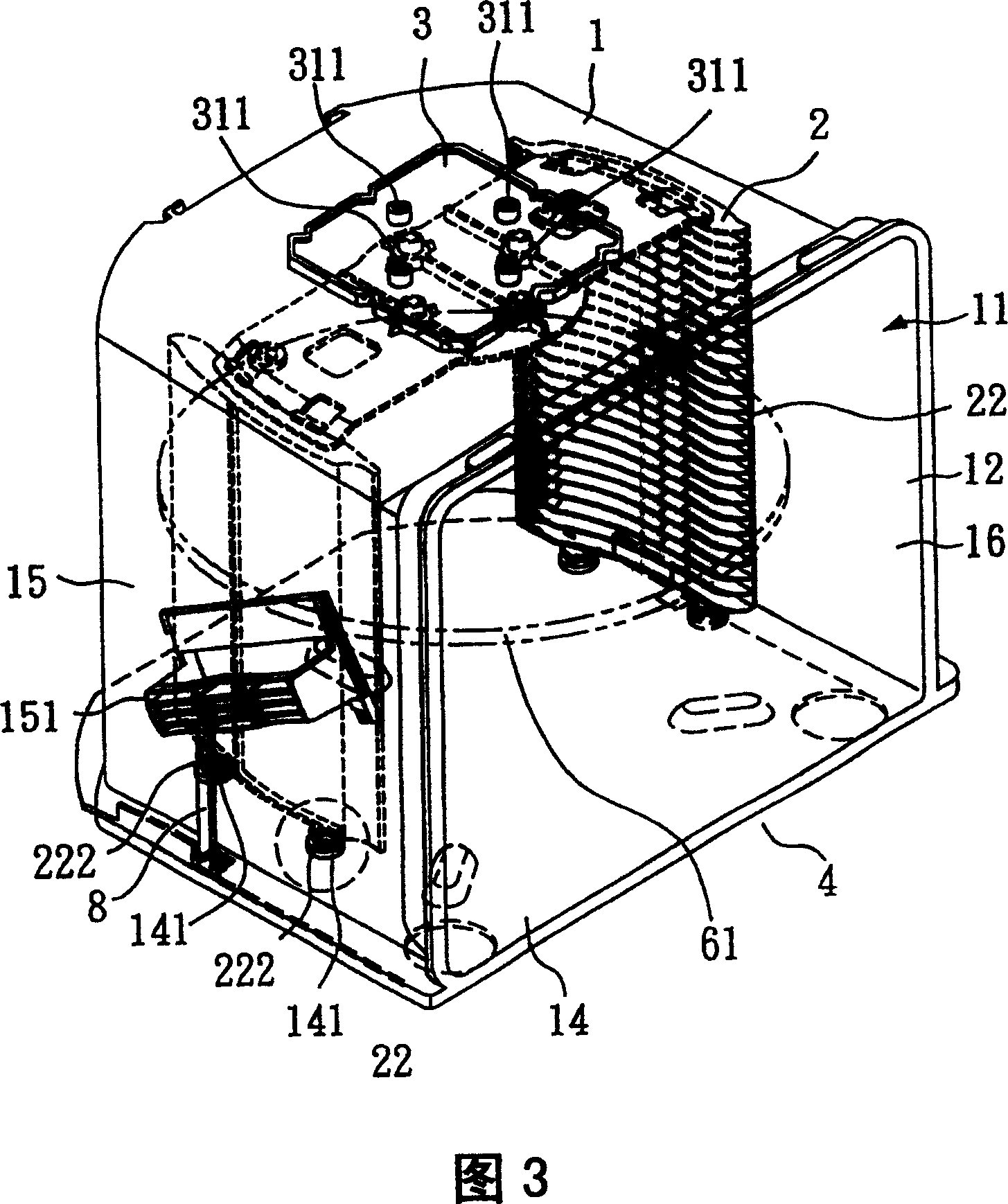

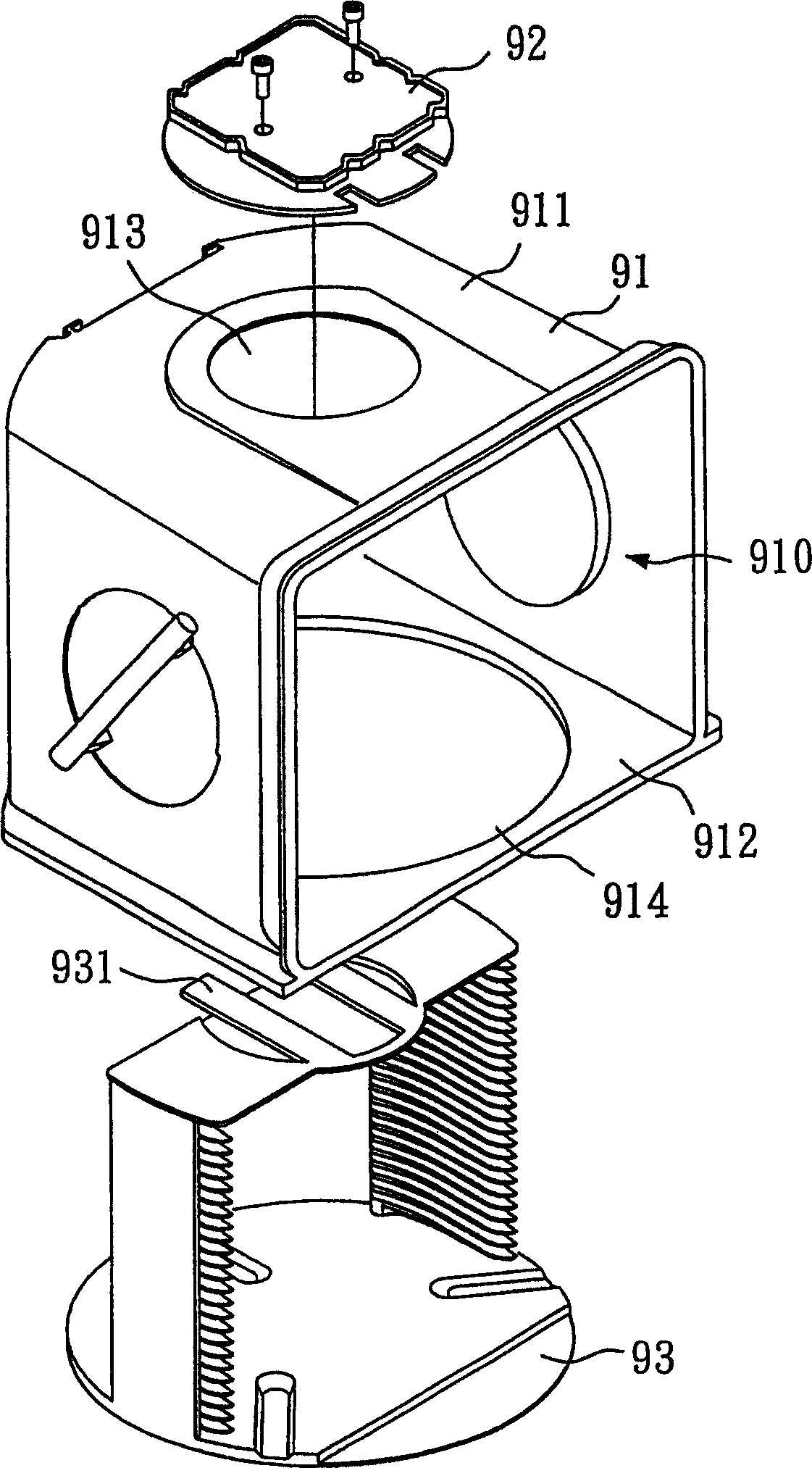

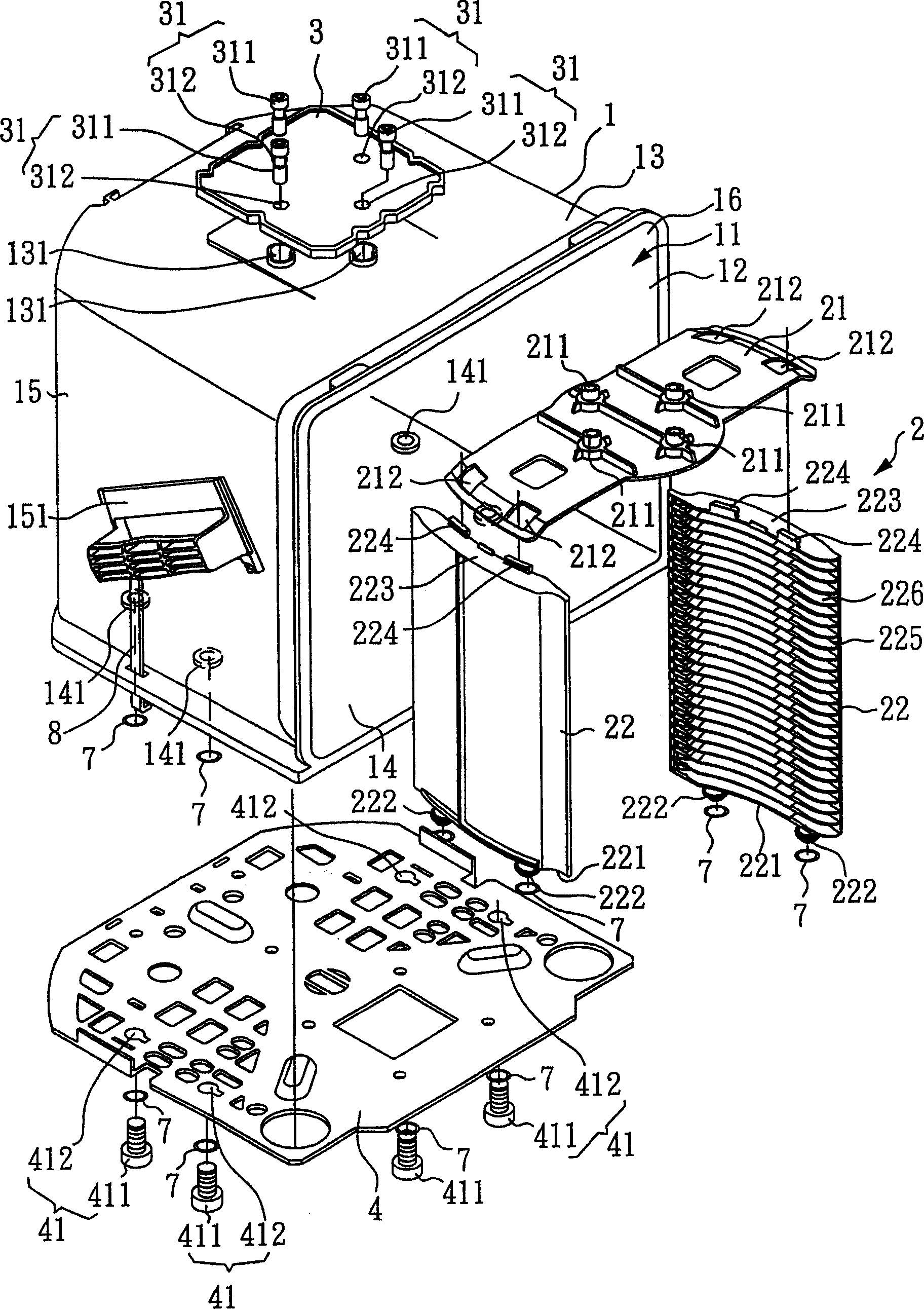

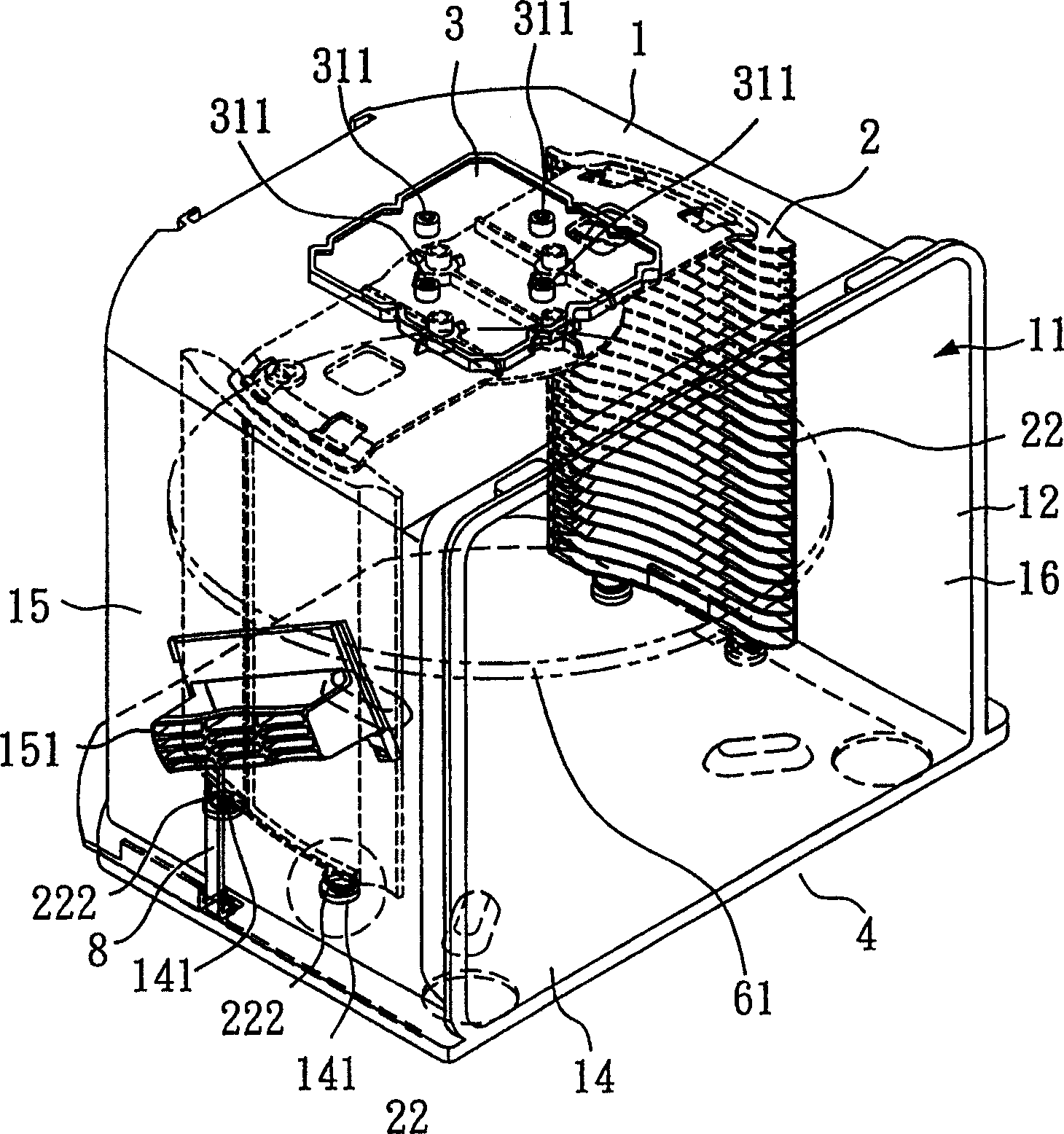

Clean container structure

InactiveCN1313331CAffects slot position accuracyExcellent force transmissionSemiconductor/solid-state device manufacturingDamagable goods packagingEngineeringAir tightness

Owner:IND TECH RES INST

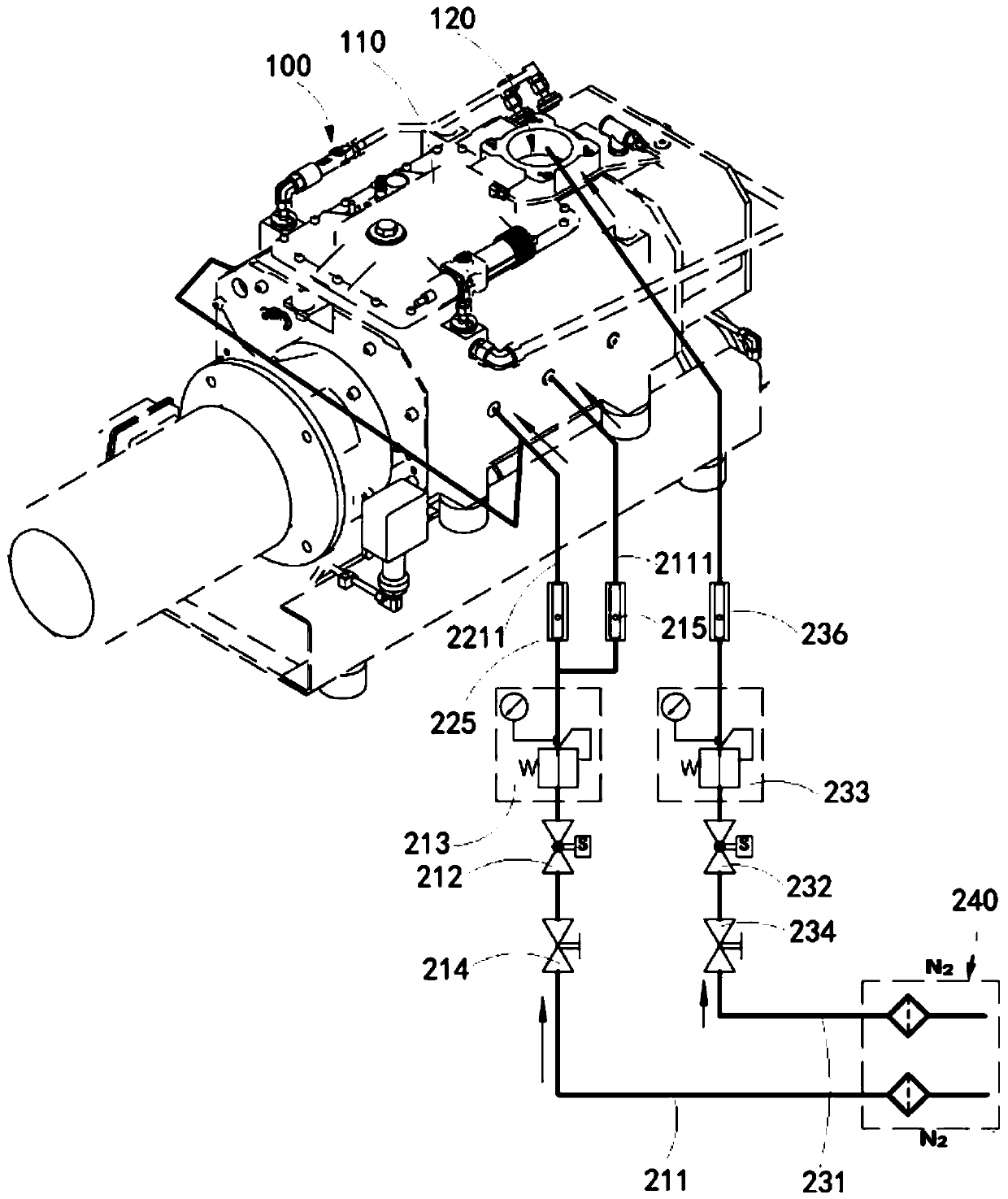

Dry vacuum pump and crude oil vacuum flash evaporation treatment device

InactiveCN111500309ASolve prone to failure problemsGuaranteed vacuumHydrocarbon distillation control/regulationVacuum distillationControl cellVacuum pump

The invention provides a dry vacuum pump and a crude oil vacuum flash evaporation treatment device. The dry vacuum pump comprises an inert gas module, and the inert gas module comprises a gas source,a gas ballast unit, a sealing unit, a purging unit and a control unit. The gas source is used for storing inert gas. The gas ballast unit is connected between the gas source and the pump cavity of a pump body. The sealing unit is connected between the gas source and the sealing ring of the pump body. The purging unit is connected between the gas source and an inlet pipeline of the pump body. The control unit is connected with the gas ballast unit, the sealing unit and the purging unit. The control unit is configured to control the gas ballast unit to convey inert gas to the pump cavity at a first pressure and a first flow when the dry vacuum pump works; and controls the sealing unit to convey inert gas to the sealing ring at a second pressure and a second flow rate to form gas sealing, andis further configured to control the purging unit to purge the pump cavity through the inlet pipeline at a third pressure and a third flow rate when the dry vacuum pump stops working.

Owner:ZHONGSHAN KAIXUAN VACUUM SCI & TECH CO LTD

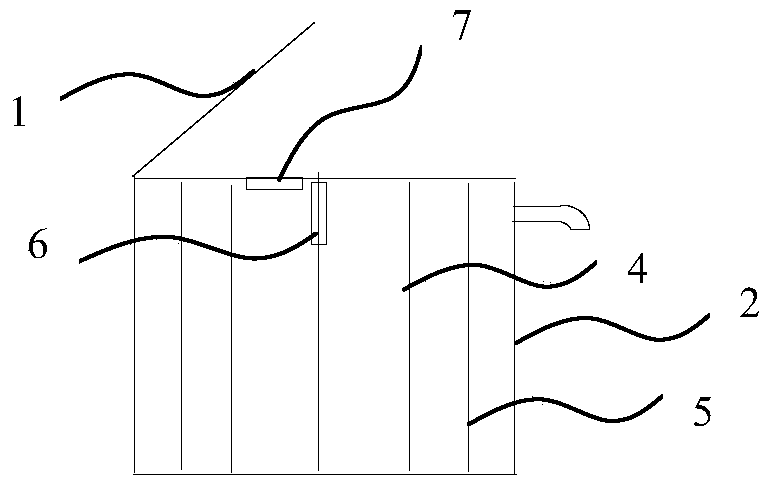

Ventilation device for outdoor switch

InactiveCN105140802AExchangeProtect operational safetySubstation/switching arrangement cooling/ventilationCold airMetallic materials

The invention provides a ventilation device for an outdoor switch. The ventilation device comprises a shell which is divided into an upper shell, a middle shell and a lower shell. The middle shell is provided with grooves at two sides. The middle part of the upper shell is provided with a connection hole. The upper shell is provided with vertical columns at two sides of the upper shell. A ventilation cavity is divided into a U-shaped upper cavity and a lower cavity. The ventilation cavity is a maze type sealed structure. The end part of the lower shell is provided with an air inlet, and a filtering layer is arranged between the air inlet and the lower cavity. According to the ventilation device, the maze type sealed structure is employed, the exchange of hot and cold air between switch equipment and an environment can be realized, the temperature difference between the internal part of a switch equipment cabinet and the environment is eliminated, the metal material corrosion and insulation intensity decrease caused by condensation possibly caused by the temperature sudden change in the switch equipment are avoided, a filter layer is arranged between an inlet and the lower cavity, the water molecules in the air can be effectively filtered, and the operation safety of the switch equipment is protected.

Owner:江苏华厦电力成套设备有限公司

Clean container structure

InactiveCN1743248AAffects slot position accuracyExcellent force transmissionSemiconductor/solid-state device manufacturingDamagable goods packagingAir tightnessEngineering

A clean container is disclosed. A bracing frame is placed into the clean container directly from it's front opening, which is made integrally with the inner chamber of the clean container. There is an upper assistant plant at the upper part of the container and there is a lower assistant plate at the lower part of the container. The two plates are combined with the bracing frame. Advantages: simple production and assembling, good structure strength and air tightness.

Owner:IND TECH RES INST

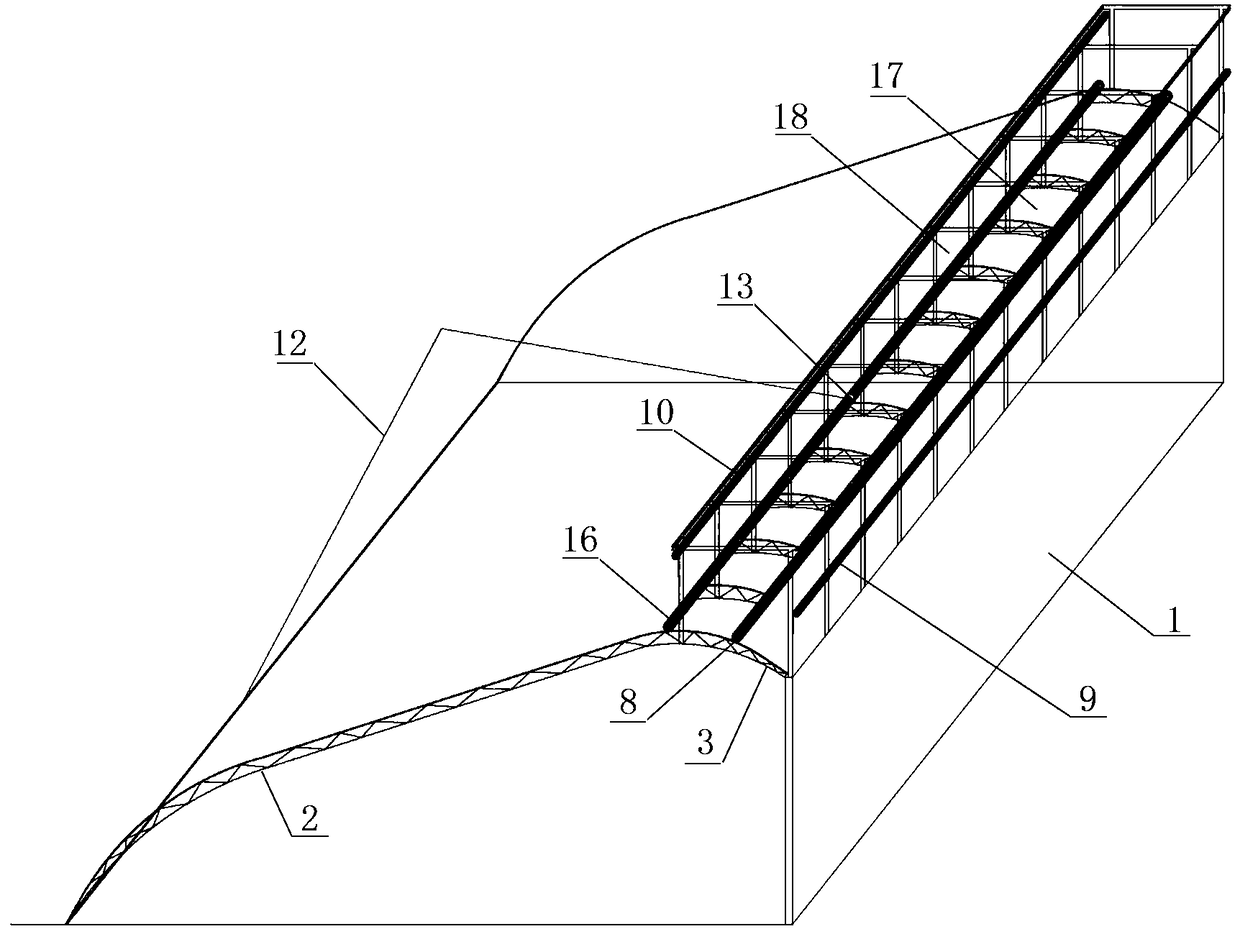

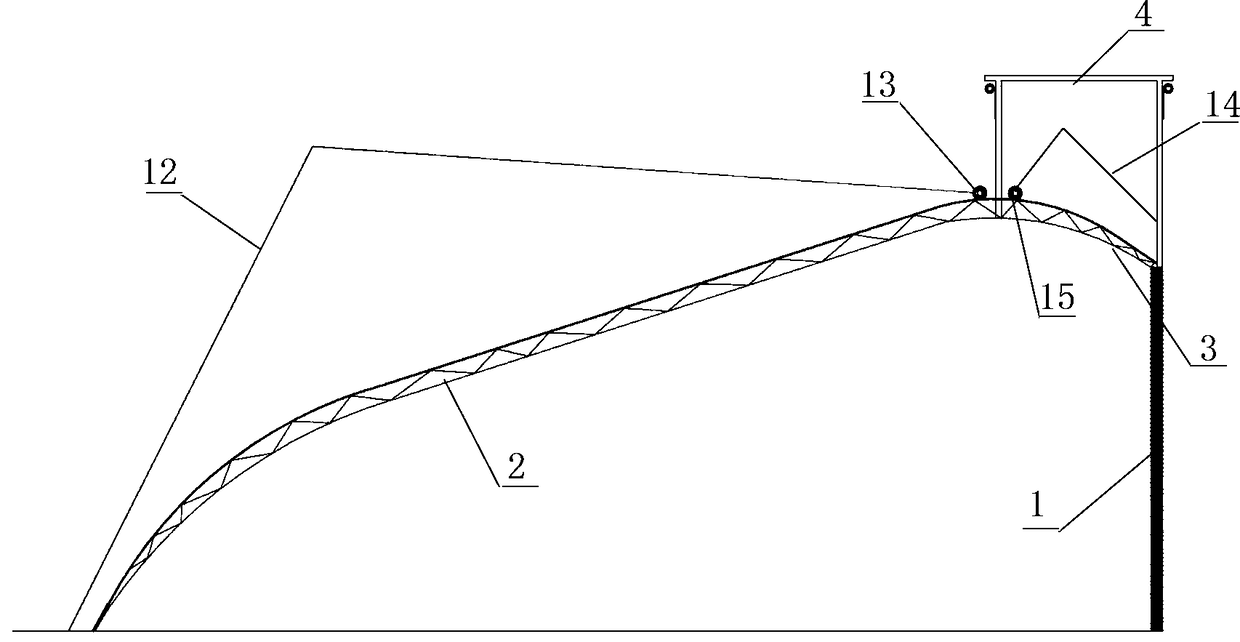

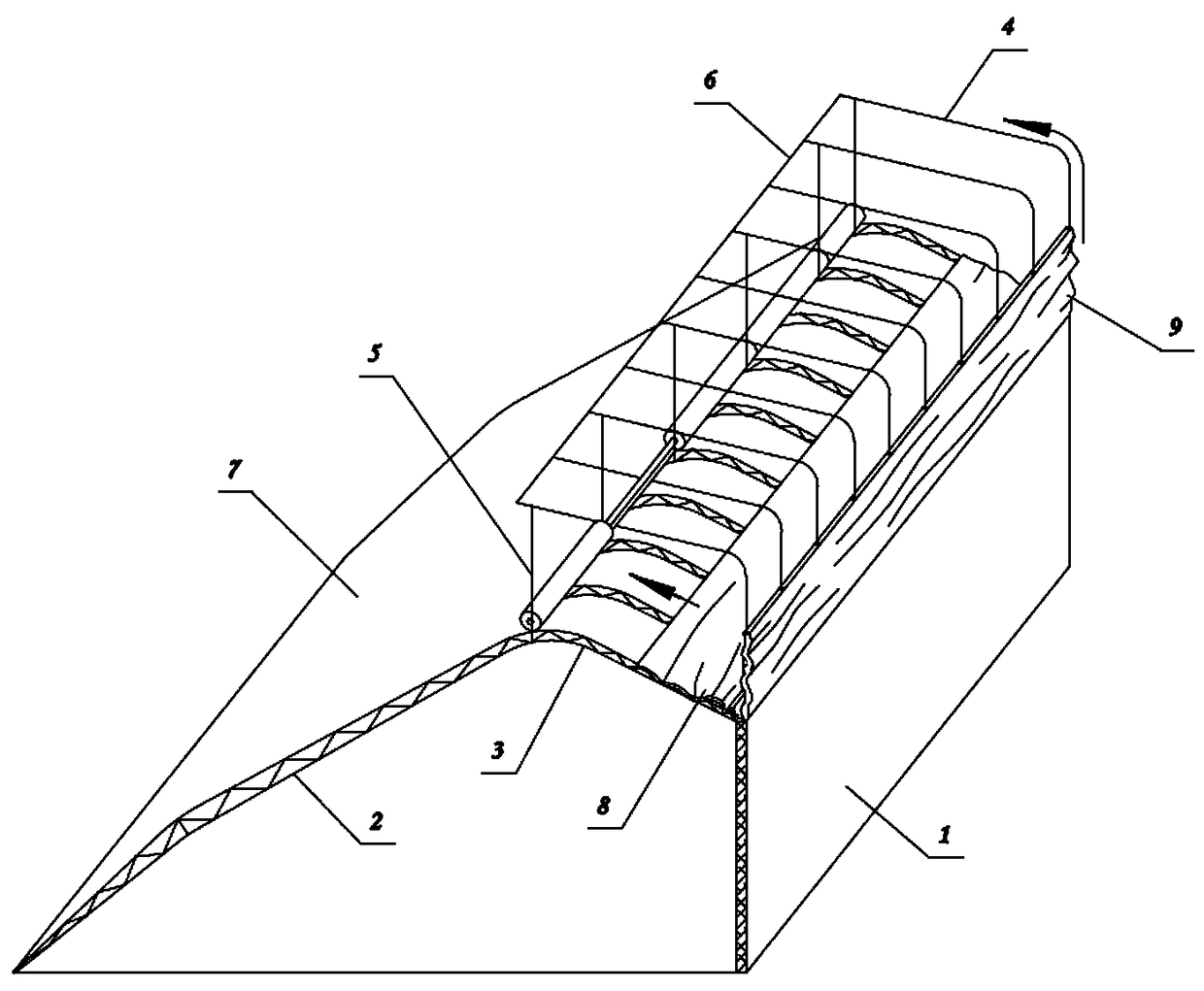

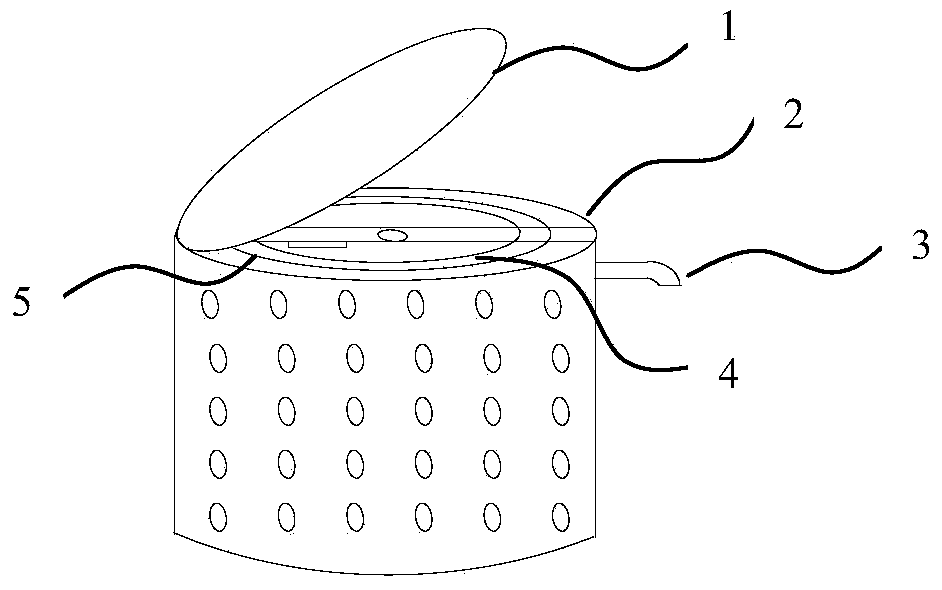

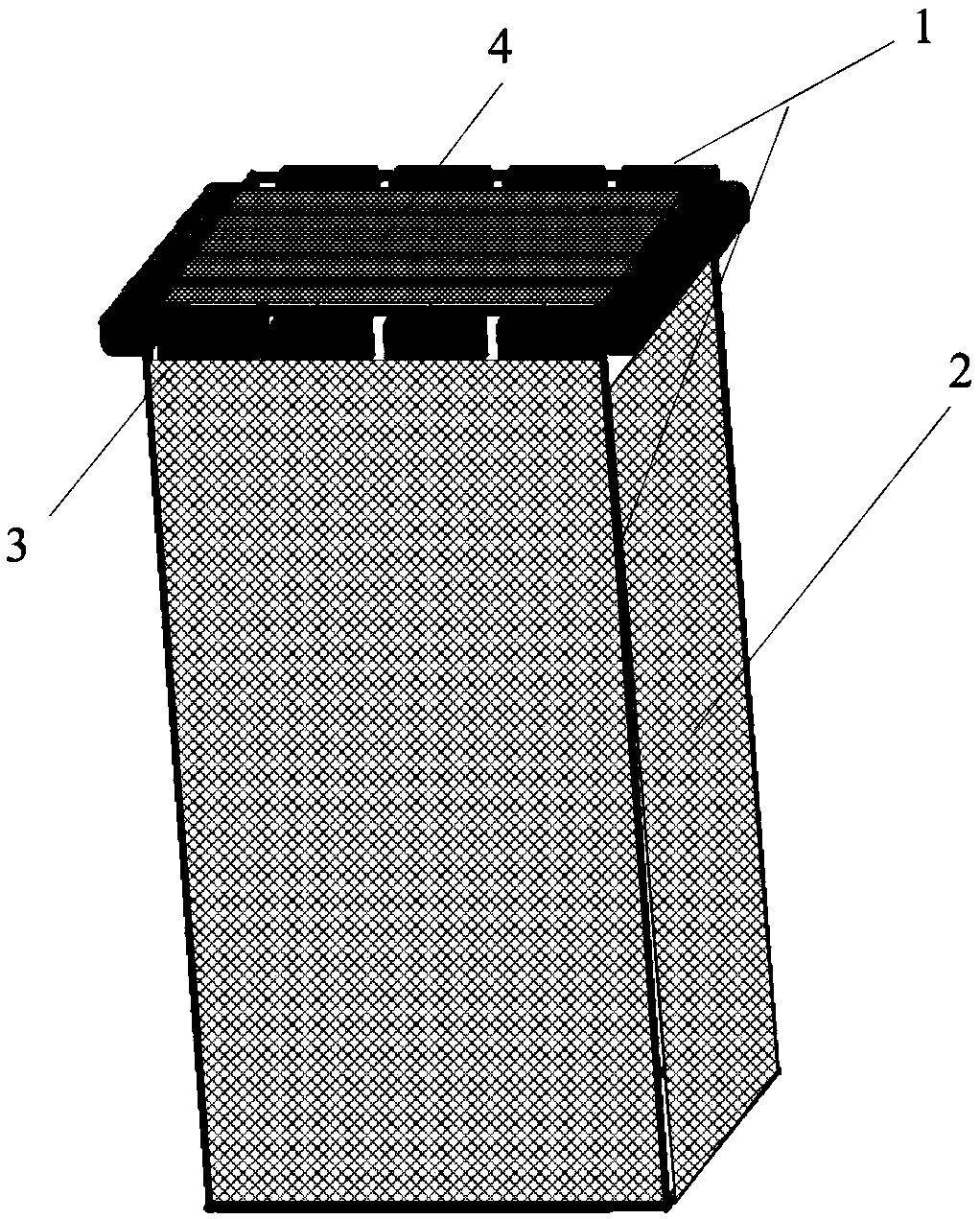

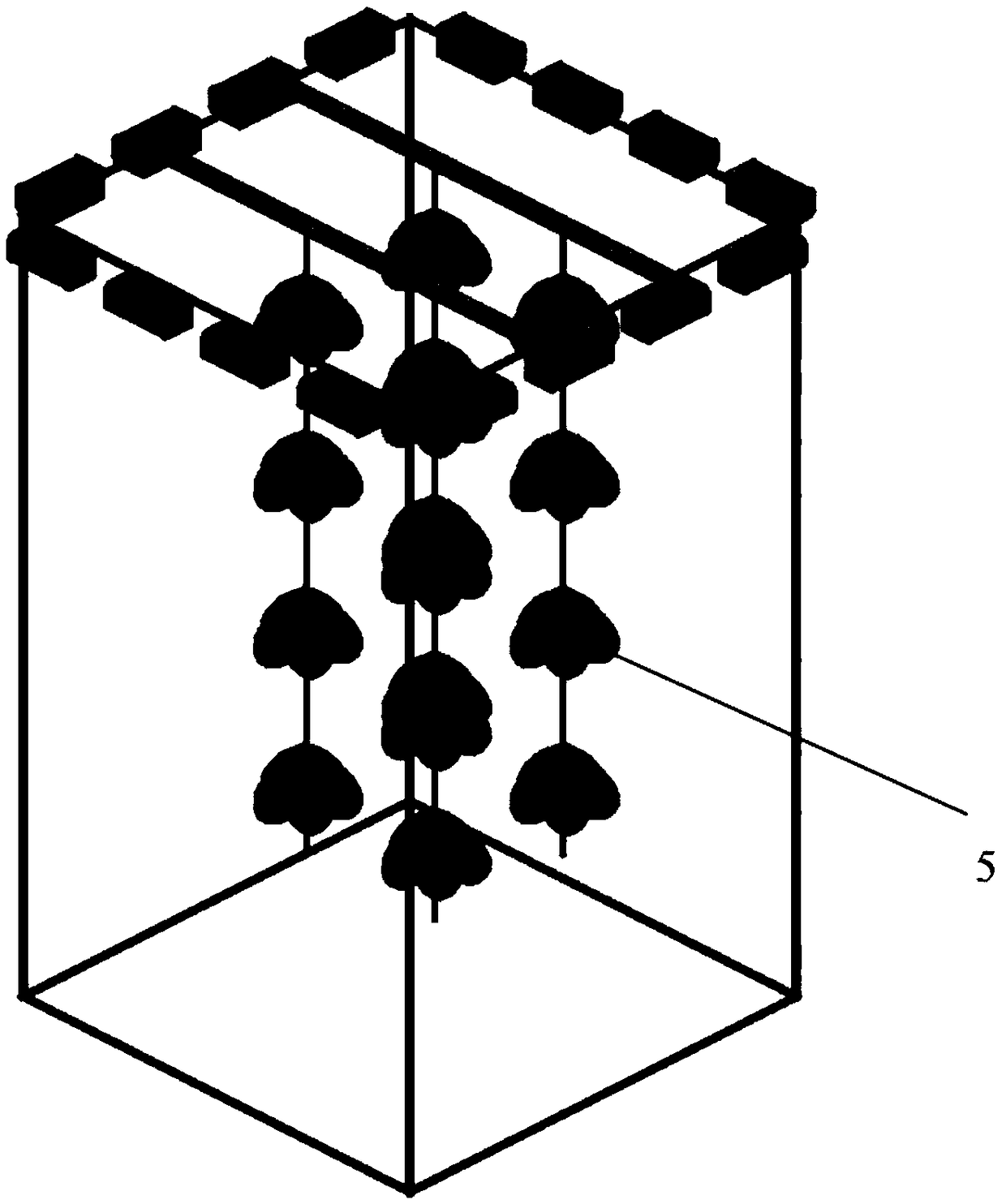

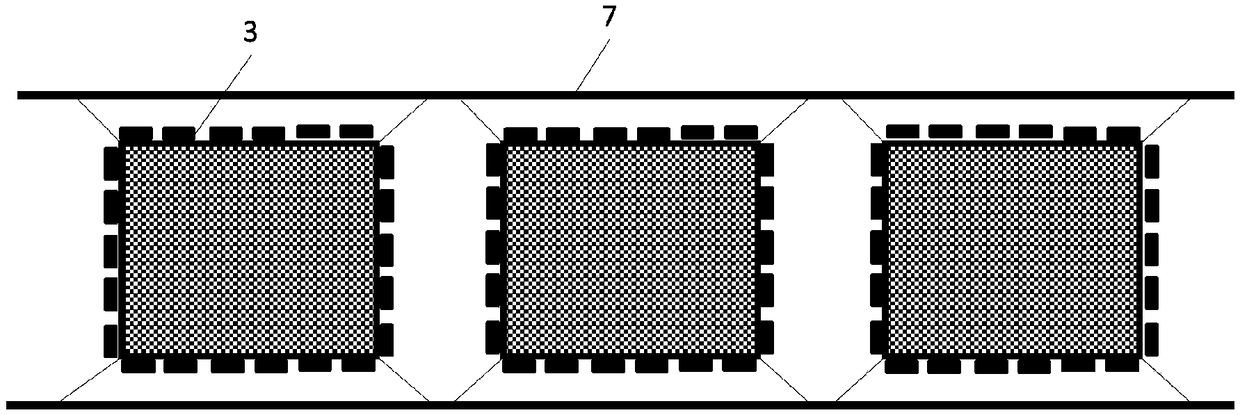

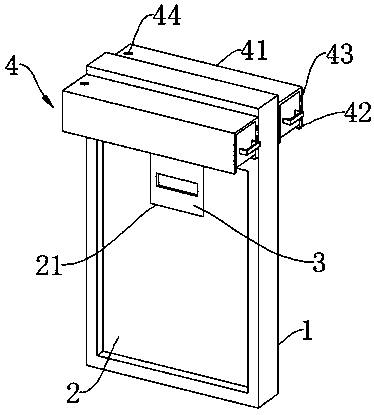

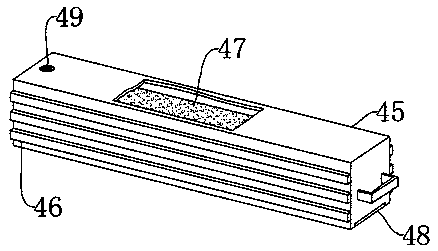

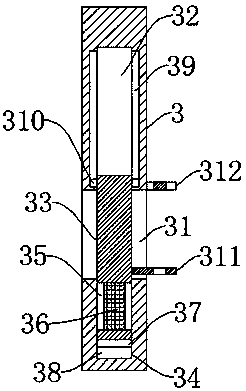

Patinopecten yessoensis spat breeding device and method

ActiveCN109042412APrevent flightEasy to harvestClimate change adaptationPisciculture and aquariaFisheryBuoy

The invention relates to a patinopecten yessoensis spat breeding device and method, and belongs to the technical field of patinopecten yessoensis spat breeding. The patinopecten yessoensis spat breeding device comprises a net cage, and the net cage comprises a frame (1), a bolting silk net (2), buoys (3) and a sunshade net (4), wherein the bolting silk net (2) is arranged around the frame and on the bottom of the frame; the buoys (3) are arranged around the top of the net cage, and the sunshade net (4) is arranged on the top of the net cage. The device further comprises an attachment bag (5) which is separated from the net cage, and the attachment bag can be hung in the net cage. By means of the breeding device, breeding and attached growth of patinopecten yessoensis can be achieved in offshore open sea without manually adding baits, the quality and the quantity of the survival patinopecten yessoensis spat can be ensured, and the high-quality spat is provided for bottom sowing.

Owner:DALIAN OCEAN UNIV

A kind of sn-zn-bi series lead-free solder alloy and preparation method thereof

ActiveCN106041353BPrevent oxidationProcess stabilityWelding/cutting media/materialsSoldering mediaBonding strengthMetallic Lead

Owner:TIANJIN UNIV

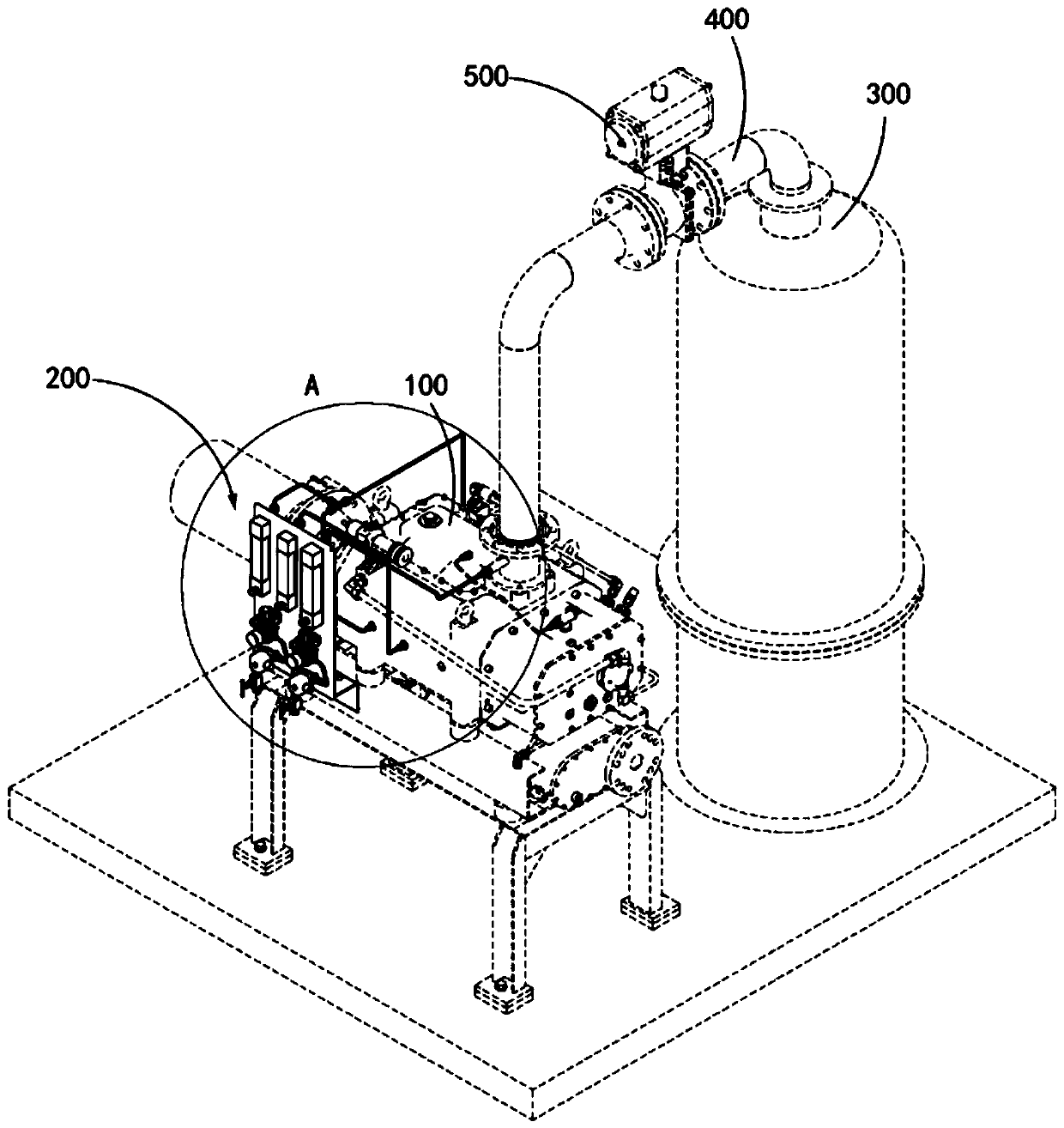

Particle removing device

PendingCN113217901AQuarantine entryReduced scour wearBoiler cleaning apparatusSteam separation arrangementsParticulatesSteam turbine blade

A particle removing device comprises a separator and a collecting device which are arranged in a steam pipeline, and the separator is connected with the collecting device. A discharging pipe is arranged on the collecting device, a valve is arranged on the discharging pipe, and the discharging pipe is located outside the steam pipeline. According to the particle removing device, solid particles in steam can be prevented from scouring a valve pipeline and turbine blades and causing abrasion, the solid particles in the steam can be prevented from causing jamming of a turbine adjusting valve and the like, and it is guaranteed that the turbine adjusting valve and the like can be normally closed when needed so as to effectively cut off steam entering a turbine, prevent the overspeed of a unit and ensure the safety of the unit.

Owner:XIAN THERMAL POWER RES INST CO LTD

Modified amide wax slurry anti-rust coating for building scaffold as well as preparation method thereof

InactiveCN109913119AImprove water resistanceImprove adhesionAnti-corrosive paintsPolyamide coatingsPotassiumSlurry

The invention discloses modified amide wax slurry anti-rust coating for a building scaffold as well as a preparation method thereof. The modified amide wax slurry anti-rust coating for the building scaffold is prepared from the following raw materials in parts by weight: 50 to 100 parts of amide wax slurry, 2 to 5 parts of cobalt naphtenate, 1 to 5 parts of lead chromate yellow, 0.15 to 0.2 part of phthalocyanine blue, 5 to 8 parts of potassium methyl silanol, 2 to 4 parts of quaternary ammonium salt, 15 to 18 parts of sulfonated oil, 10 to 13 parts of titanium dioxide, 2 to 5 parts of fluorocarbon resin, 1 to 3 parts of rosin, 0.2 to 1.5 parts of a base material modifier, 0.5 to 0.8 part of aid and 12 to 35 parts of deionized water. The anti-rust coating enhances the adhesive force and the compactness between a coating film and a base material so as to effectively isolate water molecules, chloridions and sodium ions from entering the basic material and the base material and improve the adhesive force, the water resistance and the flash rust resistance of the coating film under the wet environment, and has excellent adhesive force, water resistance, salt fog resistance, flash rustresistance, acid and alkali resistance and corrosion resistance.

Owner:CHINA CONSTR SEVENTH ENG BUREAU THE SECOND CO LTD

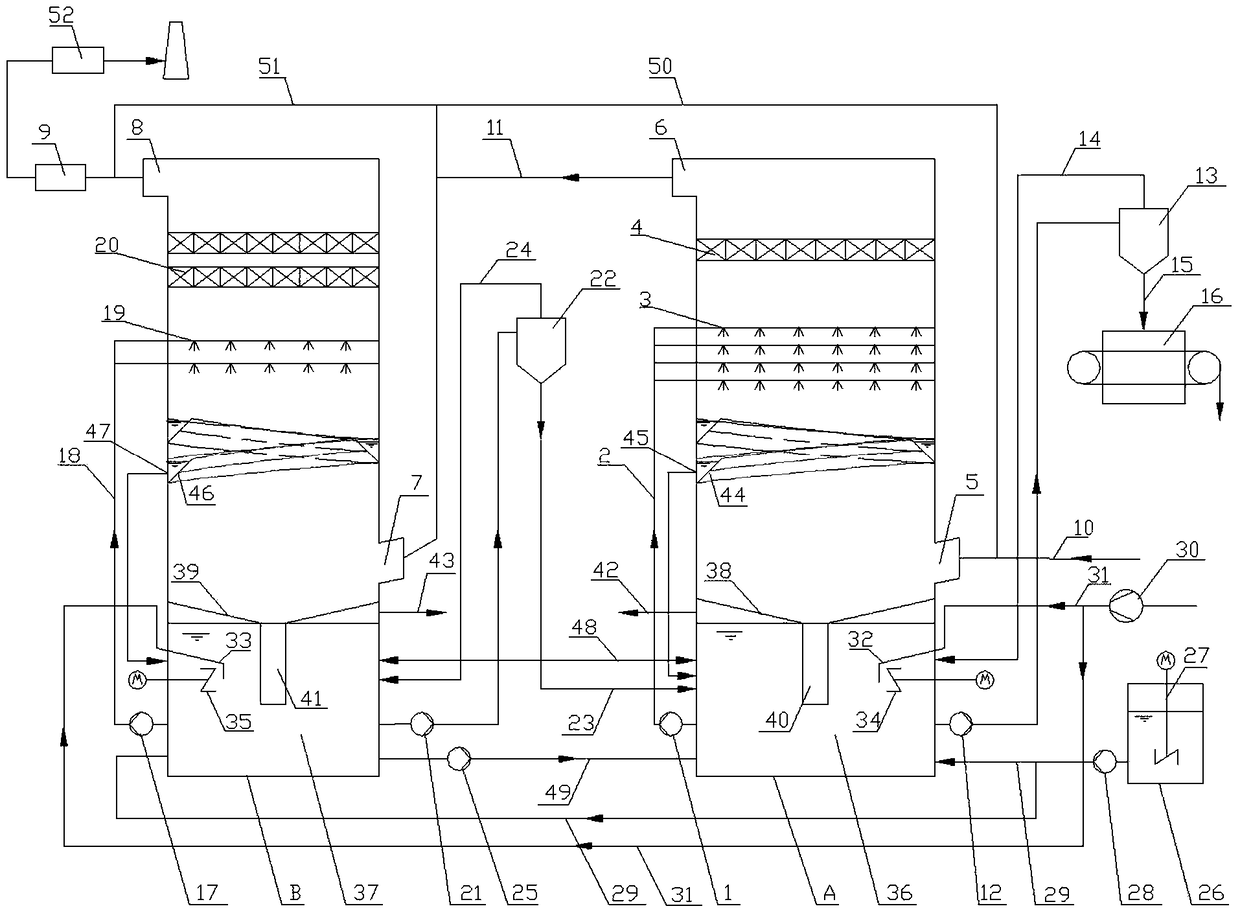

A double-tower high-efficiency wet desulfurization device

ActiveCN105709585BIncrease contact timeMeet desulfurization requirementsGas treatmentDispersed particle separationFlue gasEmission standard

The invention discloses a double-tower efficient wet desulphurization device which comprises four subsystems including the SO2 absorption system, the slurry supply system, the oxidation air system and the gypsum dehydration system. The SO2 absorption system is composed of a primary desulphurization tower and a secondary desulphurization tower which are of the same structure, are connected in series and share a set of the slurry supply system and the oxidation air system, gypsum slurry in the secondary desulphurization tower is delivered into the primary desulphurization tower, and gypsum in the primary desulphurization tower is discharged out of the tower through the gypsum dehydration system. The double-tower efficient wet desulphurization device has the advantages of being high in desulphurization efficiency, wide in application range, stable in operation, convenient to maintain and overhaul and the like. Flue gas purified by the desulphurization device can meet the increasingly strict SO2 ultralow emission standard of China, and meanwhile waste oxidation air and the purified flue gas are isolated, so that the device is beneficial for improving the capturing efficiency of a follow-up CO2 purifying system.

Owner:HUNAN HUAYI MUNICIPAL ENG DESIGN

An energy-saving closed-loop spray drying system

ActiveCN106166396BQuality assuranceAvoid pollutionMultiple-effect/fractional condensationEvaporator accessoriesEngineeringNitrogen gas

The invention discloses an energy-efficient closed-cycle spray drying system. The energy-efficient closed-cycle spray drying system comprises a vacuum pump, a degassing tank, a filter, an atomizer, a gas content detector, a spray drying tower, a cyclone separator, an induced draught fan, a refrigerant circulation loop, a heat exchanger, a nitrogen supplementary device, an electric heater, and the like. The energy-efficient closed-cycle spray drying system can be used for recycling and reusing of heat energy of steam discharged from drying towers, and recycling and reusing of organic solutions in the steam at the same time. In the energy-efficient closed-cycle spray drying system, high temperature nitrogen is taken as drying gas, so that product quality is improved effectively, and oxidation of products in production process is avoided.

Owner:常州市海正药化设备有限公司

Tin-zinc lead-free solder and preparation method thereof

InactiveCN106624431AHigh strengthReduce contact resistanceWelding/cutting media/materialsSoldering mediaBall millMaterials science

The invention provides a tin-zinc lead-free solder and a preparation method thereof. The tin-zinc lead-free solder comprises, by weight, 5%-10% of zinc, 0.1%-0.2% of nickel, 0.6%-2.4% of graphene and the balance tin. The preparation method comprises the steps that (1) a pure zinc ingot, a pure nickel ingot and a pure tin ingot are sealed in a vacuum quartz tube, and then the vacuum quartz tube is filled with high-purity nitrogen protective gas; (2) the raw materials sealed in the step (1) are put into a reaction furnace to be subjected to smelting heat treatment, and the raw materials are completely melted into molten liquid; (3) the graphene is placed in a stirring type ball mill, the stirring type ball mill is filled with liquid nitrogen till a milling ball is completely submerged, then ball milling is conducted, powder obtained through ball milling is taken out and added into the molten liquid in the step (2), and stirring and heat preservation treatment are conducted; and (4) after the graphene in the step (3) and the molten liquid are uniformly smelted, slagging off is conduced, the molten raw materials are subjected to casting forming, and thus the tin-zinc lead-free solder is obtained. The tin-zinc lead-free solder has good welding spot bonding strength and meanwhile can have good oxidation resistance.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

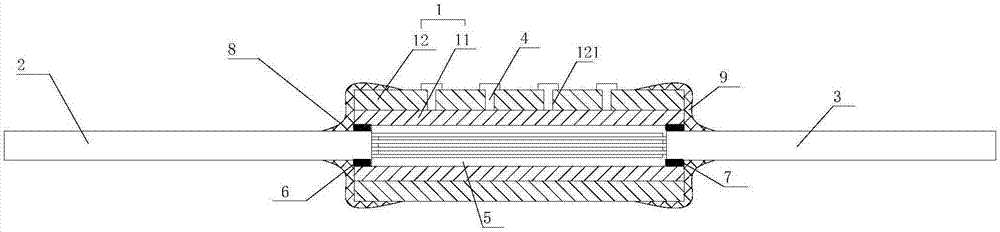

Copper aluminum conducting wire connection structure of high safety

PendingCN107394422AOxidation protectionEffectively isolate entryClamped/spring connectionsConnection contact member materialElectrical resistance and conductanceElectric energy

The present invention provides a copper aluminum conducting wire connection structure of high safety. The copper aluminum conducting wire connection structure comprises a sleeve, a copper conducting wire, an aluminum conducting wire and a plurality of screws, the sleeve comprises a plastic inner layer and a metal outer layer, and a plurality of threaded holes are arranged at intervals on the metal outer layer and along the axial direction of the sleeve. The bare conductive core wires of the copper conducting wire and the aluminum conducting wire are placed in a fixed inner cavity of the sleeve from the two ends respectively, are interlaced parallelly and are inserted mutually, so that the circumferential surfaces of the bare conductive core wires of the copper conducting wire and the aluminum conducting wire are contacted and connected mutually and electrically. The plurality of screws penetrate the plurality of threaded holes respectively to press against the plastic inner layer to thereby lock and fix the bare conductive core wires of the copper conducting wire and the aluminum conducting wire in the fixed inner cavity. According to the present invention, the bare conductive core wires of the copper conducting wire and the aluminum conducting wire adopt an interlaced connection mode, so that the connection resistance is not generated, and the electric energy can be saved. The sleeve of the present invention is composed of the plastic inner layer and the metal outer layer, and the plastic inner layer can play an insulation part, protects the oxidation of a copper aluminum core wire, at the same time, also can realize a waterproof effect.

Owner:蚌埠博令电子科技有限公司

Micro-electronic assembly soldering paste and preparation method thereof

InactiveCN113510406AAvoid reunionImprove dispersion uniformityWelding/cutting media/materialsSoldering mediaGraphiteGraphene

The invention discloses micro-electronic assembly soldering paste and a preparation method thereof. The soldering paste comprises tin powder and soldering flux, the weight ratio of the tin powder to the soldering flux is (82-95): (8-15), and the tin powder comprises the following components in parts by weight: 80-90 parts of tin, 1-2 parts of silver, 1.5-2 parts of copper, 0-1.5 parts of nano titanium particles, 0.5-1.5 parts of graphene and 0.5-1 part of a graphene dispersing agent; the soldering flux comprises the following components in parts by weight: 4-6 parts of rosin, 3-5 parts of a solvent, 0.8-2 parts of an activating agent, 0.2-0.5 part of a thixotropic agent, 0.1-0.5 part of an antioxidant and 0.5-1 part of a solder paste dispersing agent. Graphene can be uniformly dispersed in tin powder through the graphene dispersing agent, the phenomenon that the graphene is agglomerated when the tin powder and the soldering flux are mixed is prevented, the dispersion uniformity of the graphene in the whole soldering paste system is improved, and the uniform and same heat dissipation performance can be kept on the whole after soldering.

Owner:江苏三沃电子科技有限公司

Lead-free paste soldering material and preparation method thereof

InactiveCN106475703BReduce contact resistanceImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaFilm-forming agentGraphite

The invention proposes a lead-free paste welding material and a preparation method thereof. The lead-free paste welding material is prepared by mixing lead-free solder alloy powder with a flux according to a mass ratio of 10-11: 0.9-1.2; the lead-free solder alloy powder is prepared by the following raw materials: 5-10 wt% of Zn, 0.1-0.2 wt% of Ti, 0.6-2.4 wt% of graphene, and the balance of Sn; and the flux has the following components: 40-50 wt% of adhesive film forming agent, 3-12 wt% of activating agent, 2-8 wt% of thixotropy anti-sinking slipping agent, and the balance of solvent. The preparation method comprises the following steps: the lead-free solder alloy powder and the flux are mixed according to the mass ratio of 10-11: 0.9-1.2; the flux is firstly put in a synthesizer; then, solder powder of the lead-free solder alloy powder is added; the synthesizer is sealed; then, a vacuum system is started for vacuumizing to fill nitrogen to reach positive pressure; a stirring system is started for stirring; the stirring is stopped; and the discharge is performed to obtain the lead-free paste welding material. The lead-free paste welding material is excellent in welding point combination strength; and meanwhile, the flux is better in oxidation resistance without needing to add antioxidant.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

Tin soldering paste for tin soaking machine

InactiveCN108145338AModerate viscosityStrong thixotropyWelding/cutting media/materialsSoldering mediaSolder pasteTin

The invention discloses tin soldering paste for a tin soaking machine. According to the weight percentage, the tin soldering paste for the tin soaking machine is made by mixing 85%-90% of lead-free solder alloy powder and 10%-15% of paste flux; the lead-free solder alloy powder comprises, by weight percentage, 5%-10% of zinc, 0.1%-0.2% of nickel, 0.4%-0.7% of copper, 2%-3.5% of bismuth, 0.8%-2.1%of graphene and the balance tin; and components of the paste flux comprise 35wt%-45wt% of an adhering film-forming agent, 0.5wt%-2wt% of modified rosin, 1%-2 % of castor oil diacyl antioxidant, 3%-6%of fluoroborate and the balance an organic solvent. The tin soldering paste is proper in viscosity and high in thixotropy, layering is not prone to occurrence during dispensing of a glue dispenser, and the tin soldering paste can be uniformly coated in an assigned welding area; oxidization of Zn in fused solder can be inhibited, and the anti-oxidizing performance of a solder alloy is remarkably improved; and the copper consumption phenomenon is sufficiently prevented.

Owner:明光顺和自动化设备科技有限公司

High-rise building fireproof type ventilating window

InactiveCN110259349AAvoid spreadingAffect personal safetyFireproof doorsVentilation arrangementFlame spreadEngineering

The invention discloses a high-rise building fireproof type ventilating window. The high-rise building fireproof type ventilating window comprises a frame, fireproof glass is fixedly installed in the frame, a rectangular opening is formed in the fireproof glass, a ventilating board is fixedly installed in the rectangular opening, and fireproof devices are fixedly installed on the upper parts of the side walls of the two sides of the frame. The fireproof devices comprise strip-type blocks fixedly connected with the frame side wall, dry powder boxes are slidably connected into straight grooves formed in the bottoms of the strip-type blocks in a clamping mode, the dry powder boxes are filled with dry powder, plastic boards are arranged at the bottoms of the dry powder boxes, when a flame spreads upwards, the plastic boards at the bottoms of the dry powder box of the fireproof devices are melted away, at the moment, the dry powder filled in the dry powder boxes fall downwards under the action of gravity to realize fire fighting work on the flame, greater property loss is prevented from being caused due to a fire behavior spreading inside a house through a window, or the situation that the personal safety of residents is affected is avoided; meanwhile, the fireproof devices are arranged on the two sides of the frame inside the house and outside the house synchronously, and the situation that when the house is on a fire, the fire behavior spreads out of the window from the window, and the residents on the upper layer are burnt is avoided.

Owner:SINO RISING SUN CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com