Modified amide wax slurry anti-rust coating for building scaffold as well as preparation method thereof

An anti-rust coating, amide wax slurry technology, applied in polyamide coatings, anti-corrosion coatings, coatings, etc., can solve problems such as limitation, excessive VOC, environmental pollution to human health, etc., to enhance adhesion and compactness, excellent adhesion. The effect of focusing and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] By weight: 50 parts of amide wax slurry, 2 parts of cobalt naphthalate, 1 part of lead chrome yellow, 0.15 parts of phthalocyanine blue, 5 parts of potassium methyl siliconate, 2 parts of quaternary ammonium salt, 15 parts of sulfonated oil, titanium 10 parts white powder, 2 parts fluorocarbon resin, 1 part rosin, 0.2 part mixture of isothiazolone and benzyl glycidyl ether, 0.5 part benzotriazole, 12 parts deionized water. According to the preparation method, the water-based anti-corrosion, anti-mildew and anti-rust paint is obtained. The water-based anti-corrosion, anti-mildew and anti-rust paint is coated on the scaffold steel structure to complete the construction.

Embodiment 2

[0028] In parts by weight: 100 parts of amide wax slurry, 5 parts of cobalt naphthalate, 5 parts of lead chrome yellow, 0.2 parts of phthalocyanine blue, 8 parts of potassium methyl siliconate, 4 parts of quaternary ammonium salt, 18 parts of sulfonated oil, titanium 13 parts of white powder, 5 parts of fluorocarbon resin, 3 parts of rosin, 1.5 parts of mixture of isothiazolone and benzyl glycidyl ether, 0.8 part of benzotriazole, 35 parts of deionized water. According to the preparation method, the water-based anti-corrosion, anti-mildew and anti-rust paint is obtained. The water-based anti-corrosion, anti-mildew and anti-rust paint is coated on the scaffold steel structure to complete the construction.

Embodiment 3

[0030] By weight: 70 parts of amide wax slurry, 3 parts of cobalt naphthalate, 3 parts of lead chrome yellow, 0.15 parts of phthalocyanine blue, 6 parts of potassium methyl siliconate, 3 parts of quaternary ammonium salt, 16 parts of sulfonated oil, titanium 12 parts of white powder, 3 parts of fluorocarbon resin, 2 parts of rosin, 1 part of substrate modifier, 0.6 parts of additive, 20 parts of deionized water. According to the preparation method, the water-based anti-corrosion, anti-mildew and anti-rust paint is obtained. The water-based anti-corrosion, anti-mildew and anti-rust paint is coated on the scaffold steel structure to complete the construction.

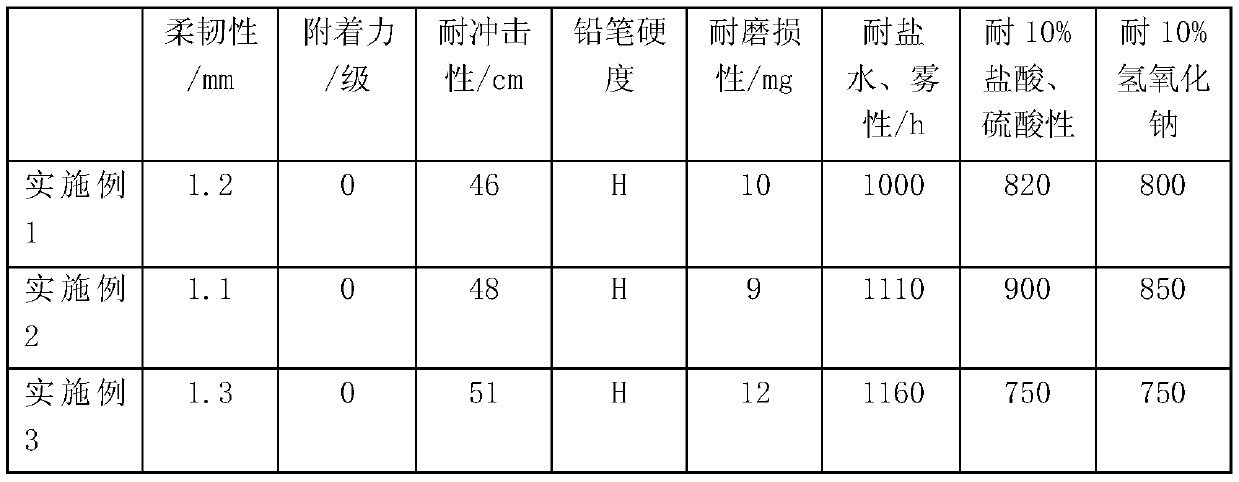

[0031] The coating performance indexes of above-mentioned three kinds of embodiments are measured as follows:

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com