Welding wire impurity-removal mechanism for welding

A technology of welding wire and welding torch, which is applied in the field of welding wire removal mechanism, which can solve the problems of secondary pollution and single type of cleaning, and achieve the effect of preventing scratching of welding wire, improving the efficiency of removing impurities, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

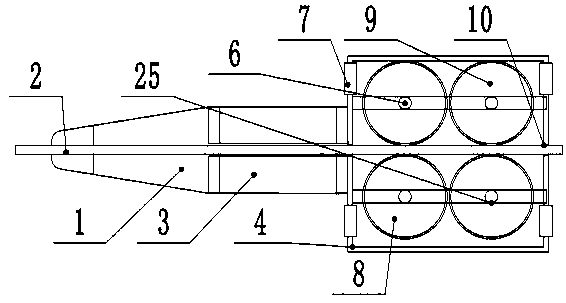

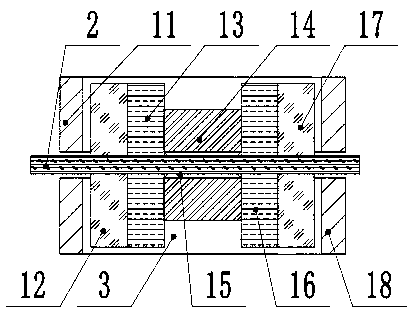

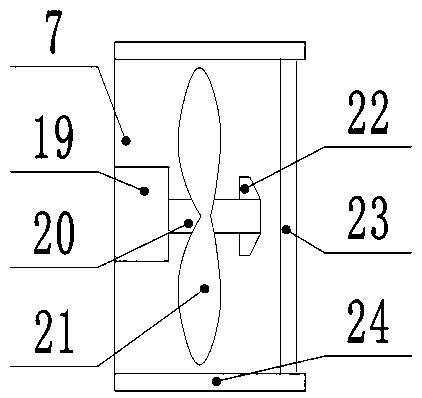

[0020] see figure 1 , a welding wire impurity removal mechanism for welding, comprising: a welding torch tip 1, a welding wire 2, a welding torch impurity removal cabin 3 and a welding wire shaping and impurity removal part 4, the welding wire 2 is a filler metal material of a molten part for welding, and the welding wire The outside of 2 is respectively equipped with welding wire shaping and removing impurities part 4, welding torch removing impurities chamber 3 and welding torch head 1 from right to left. The welding torch head 1 is fixedly installed on the outside of the welding wire 2, and the welding torch head 1 adopts a tapered structure , can effectively improve the stability of the structure of the welding torch head 1, and the front end of the conical structure can better penetrate into a narrow area for welding work and expand the scope of use. Such as figure 2 As shown, the two sides of the inside of the welding torch removal chamber 3 are respectively equipped w...

Embodiment 2

[0023] Compared with Embodiment 1, Embodiment 2 differs only in that the fan blades 21 adopt a symmetrical distribution of eight fan blades and are made of magnesium-aluminum alloy, which has good corrosion resistance and improves the stability of the equipment.

[0024] Technical principle: The welding wire 2 is shaped and removed through the welding wire shaping and removing part 4 and the welding torch removing cabin 3, which not only improves the efficiency of removing impurities but also increases the design of the shaping structure, and improves the subsequent welding quality and accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com