Special-purpose drill for hole drilling

A drill bit and drill shank technology, which is applied in the direction of wood drilling tools, wood processing tools, wood turning tools, etc., can solve the problems of large drill bit wear, workpiece becoming waste products, and small drill bit wear, so as to improve labor efficiency and labor accuracy , Reduce the probability of product reimbursement, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

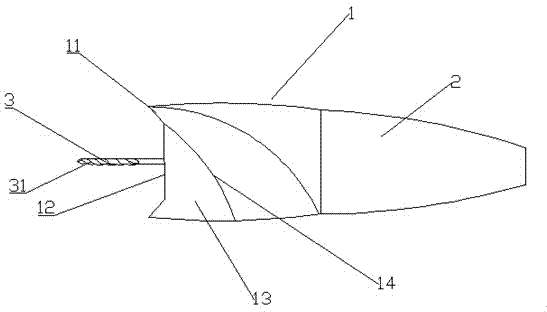

[0017] The invention relates to a special drill bit for drilling, such as figure 1 Shown: includes drill bit 1 and drill handle 2, drill bit 1 and drill handle 2 are fixedly connected, drill bit 1 includes a depth limiting device and a drill tip 3 arranged in the depth limiting device, and the drill tip 3 is provided with a spiral chip removal Groove 31, the helix angle of the flute 31 is 15-30°; the drill shank 2 is set as a cylindrical drill shank as a whole, and the diameter of the cylindrical drill shank is gradually decreasing from the other end away from the drill bit 1 to the tail end of the drill shank 2 , forming a round table-shaped drill shank as a whole,

[0018] Such as figure 1 As shown: the overall structure of the depth limiting device is: the depth limiting device is mainly a thickness limiting structure 13, and the drill tip 3 runs through the entire drill bit 2 with the center axis of the depth limiting device as the axis.

[0019] The thickness limiting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com