Tin-zinc lead-free solder and preparation method thereof

A lead-free solder, tin-zinc technology, applied in the direction of welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problems of poor reliability of joint strength solder joints, oxides without protective melt, and limited application of solder alloys, etc. , to achieve the effect of improving oxidation resistance, reducing contact resistance and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

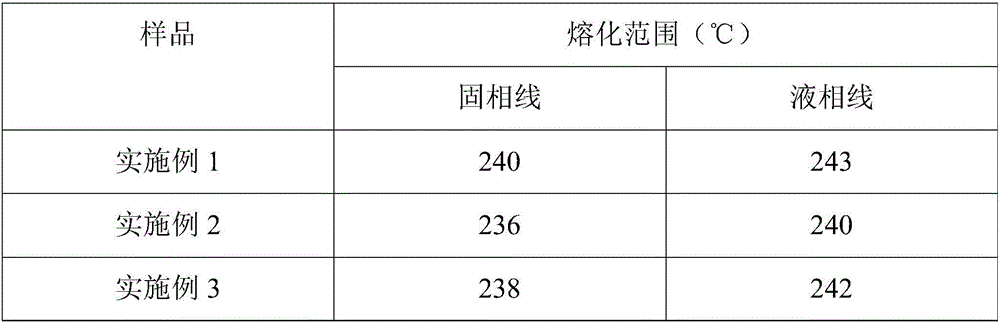

Embodiment 1

[0023] A tin-zinc lead-free solder, calculated by weight percentage, is made of the following raw materials:

[0024] 7% of zinc, 0.16% of nickel and 1.6% of graphene, and the balance is tin.

[0025] The preparation method comprises the following steps:

[0026] 1) Encapsulate pure zinc ingots, pure nickel ingots and pure tin ingots in vacuum quartz tubes, the vacuum degree is below 2.5Pa, and then fill high-purity nitrogen protective gas to 1.2×10 5 Pa;

[0027] 2) Put the packaged raw materials in step 1) into the reaction furnace to melt the melt after heat treatment at 600°C and completely melt;

[0028] 3) Put the graphene in a stirring ball mill, fill it with liquid nitrogen until the balls are completely submerged, and then perform ball milling. The mass ratio of the ball to material is 6:1. Take out the powder after ball milling and add it to the melt in step 2) Perform stirring and heat preservation treatment, the heat preservation treatment temperature is 650 ° C...

Embodiment 2

[0031] A tin-zinc lead-free solder, calculated by weight percentage, is made of the following raw materials:

[0032] 5% zinc, 0.2% nickel and 2.4% graphene, and the balance is tin.

[0033] The preparation method comprises the following steps:

[0034] 1) Encapsulate pure zinc ingots, pure nickel ingots and pure tin ingots in vacuum quartz tubes, the vacuum degree is below 2.5Pa, and then filled with high-purity nitrogen protective gas to 1.1×10 5 Pa;

[0035] 2) Put the packaged raw materials in step 1) into the reaction furnace to melt the melt after heat treatment at 650°C and completely melt;

[0036] 3) Put the graphene in a stirring ball mill, fill it with liquid nitrogen until the balls are completely submerged, and then perform ball milling. The mass ratio of the ball to material is 7:1. Take out the powder after ball milling and add it to the melt in step 2) Perform stirring and heat preservation treatment, the heat preservation treatment temperature is 650 ° C, a...

Embodiment 3

[0039] A tin-zinc lead-free solder, calculated by weight percentage, is made of the following raw materials:

[0040] 10% of zinc, 0.1% of nickel and 0.6% of graphene, and the balance is tin.

[0041] The preparation method comprises the following steps:

[0042] 1) Encapsulate pure zinc ingots, pure nickel ingots and pure tin ingots in vacuum quartz tubes, and the vacuum degree is below 2.5Pa, and then filled with high-purity nitrogen protective gas to 1.3×10 5 Pa;

[0043] 2) Put the packaged raw materials in step 1) into the reaction furnace to melt the molten liquid after heat treatment at 700°C;

[0044] 3) Place the graphene in a stirring ball mill, fill it with liquid nitrogen until the balls are completely submerged, and then perform ball milling. The mass ratio of the ball to material is 8:1. Take out the powder after ball milling and add it to the melt in step 2) Stirring and heat preservation treatment, the temperature of heat preservation treatment is 680°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com