Copper aluminum conducting wire connection structure of high safety

A connection structure and safety performance technology, applied in the direction of conductive connection, connection, connection insulation, etc., can solve the problems of poor waterproof performance, easy oxidation of electric core wires, short service life, etc., to achieve protection against oxidation, save electric energy, and reduce maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

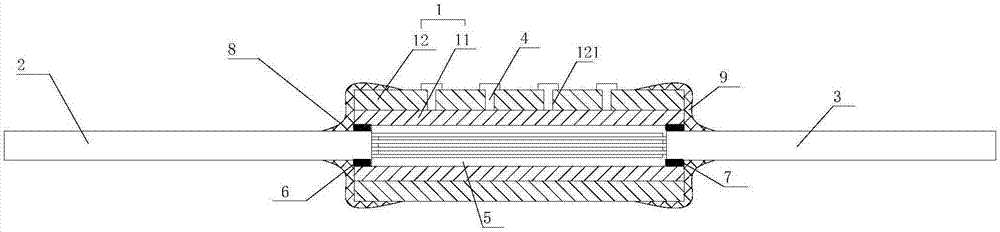

[0012] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a copper-aluminum wire connection structure with high safety performance proposed by the present invention.

[0013] refer to figure 1 , the present invention proposes a copper-aluminum wire connection structure with high safety performance, including a sleeve 1, a copper wire 2, an aluminum wire 3 and a plurality of screws 4, wherein:

[0014] The sleeve 1 is provided with a fixed inner cavity 5 extending along its axial direction. The sleeve 1 includes a plastic inner layer 11 and a metal outer layer 12. The metal outer layer 12 is provided with a plurality of threaded holes 121 at intervals along the axial direction of the sleeve 1. The depth of the threaded hole 121 is equal to the thickness of the metal outer layer 12 .

[0015] The bare conductive core wires of the copper wire 2 and the aluminum wire 3 are respectively inserted into the fixed inner cavity 5 of the casing 1 from both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com