A kind of cr/crn/craln gradient coating and preparation method for anti-oxidation at high temperature

A gradient coating and anti-oxidation technology, which is applied in coating, metal material coating process, vacuum evaporation plating, etc., to achieve excellent high temperature oxidation resistance, protection of substrate oxidation, and easy composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

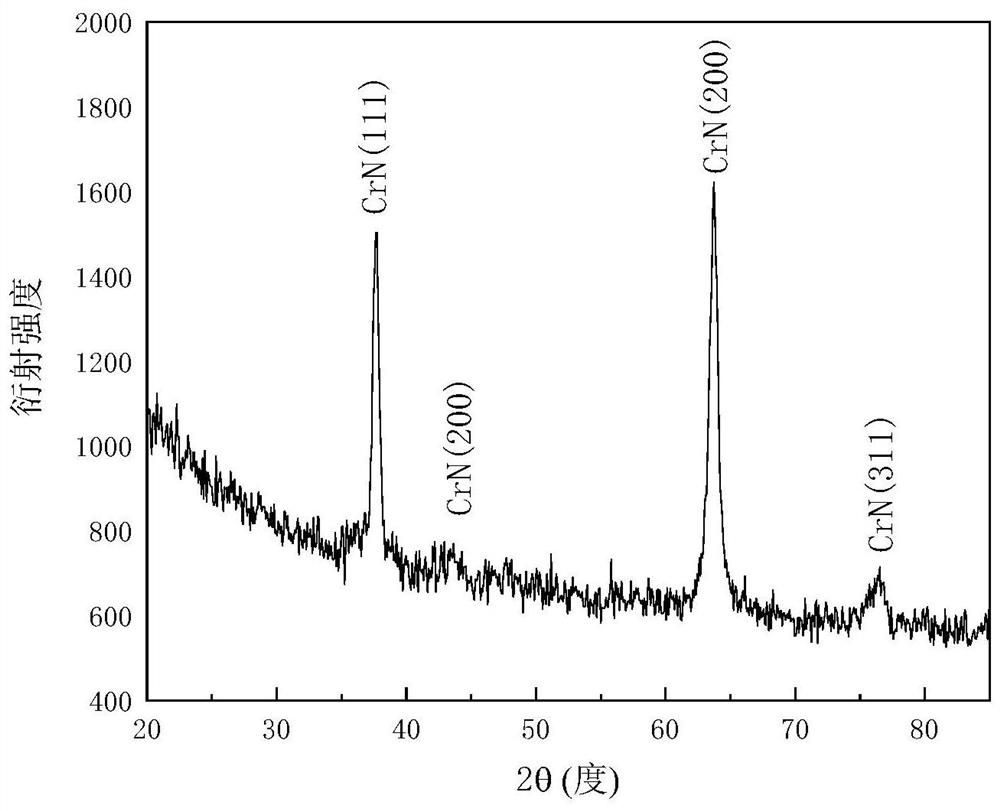

Embodiment 1

[0020] Put the 9-12% Cr heat-resistant steel substrate with a size of 7mm×7mm×1mm after sandblasting pretreatment on the surface into the vacuum coating equipment, and vacuumize it to less than 4.8×10 -6 pa, and then heat the substrate to 200°C. Open the inlet valve and fill with argon gas of 7 SCCM, and adjust the substrate bias voltage to -700V so as to remove the oxide layer on the substrate surface. Then adjust the substrate bias to -100V, turn on the DC power connected to the Cr target, and sputter the bottom layer of Cr at a power of 100W for 20 minutes, and the thickness of the bottom layer of Cr is 200nm. Then pass into the N of 7SCCM 2 , keep the Cr target power at 100W and sputter the CrN intermediate layer for 40min, and the thickness of the CrN intermediate layer is 200nm. Finally, turn on the DC power connected to the Al target, adjust the power of the Cr target to 40W, and the power of the Al target to 100W, and co-sputter the Cr-Al-N layer, and the thickness o...

Embodiment 2

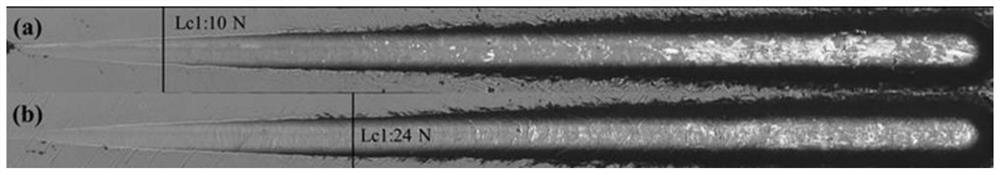

[0022] The difference from Example 1 is that the CrN / CrAlN coating does not require sputtering of the Cr bottom layer, and the sputtering time of the CrN layer is 80 min. Depend on figure 2 (a) Scratch morphology of CrN / CrAlN coating and (b) Scratch morphology of Cr / CrN / CrAlN coating, it can be seen that the Lc1 (critical fracture load) of Cr / CrN / CrAlN coating after adding Cr underlayer is much larger Based on the Lc1 of CrN / CrAlN coating, that is, adding the Cr bottom layer can significantly improve the bonding ability of the coating and steel.

Embodiment 3

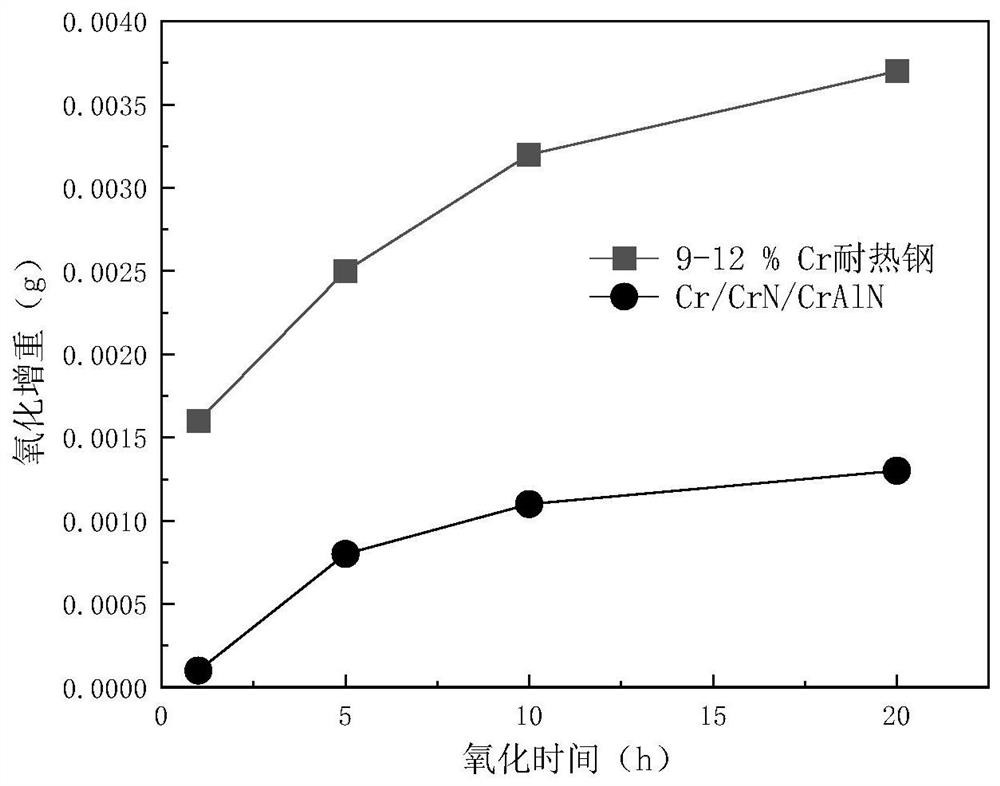

[0024] 800°C constant temperature oxidation experiment was carried out on 9-12% Cr heat-resistant steel and Cr / CrN / CrAlN coating, such as image 3 shown. The oxidation resistance of Cr / CrN / CrAlN coating at 800℃ is significantly stronger than that of 9-12% Cr heat-resistant steel.

[0025] It can be seen from Example 1, Example 2, and Example 3 that the Cr / CrN / CrAlN coating not only has good bonding ability with 9-12% Cr heat-resistant steel, but also has good high-temperature oxidation resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com