Film pasting method of color steel tile roof waterproof rolls

A technology of waterproof coiled material and color steel tile, which is applied in the direction of roof insulation materials, tools for roof engineering, roofing, etc., can solve problems such as inability to conform, affect normal work, and fail to achieve waterproofing, so as to avoid raw materials Waste, improve practicality, ensure the effect of waterproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

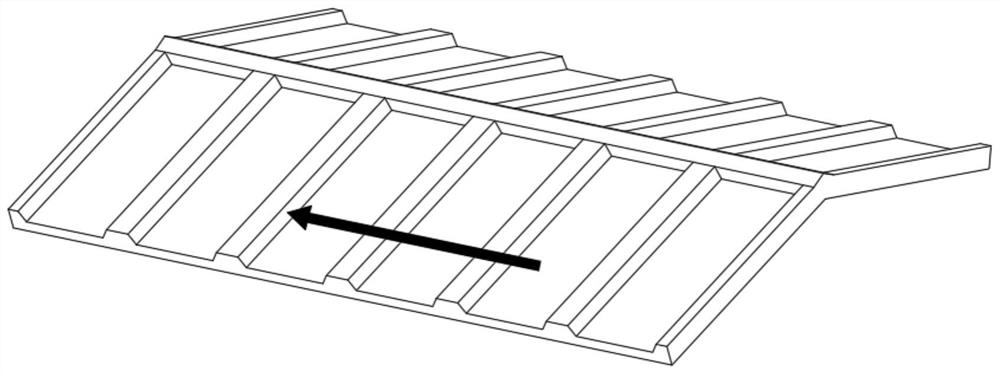

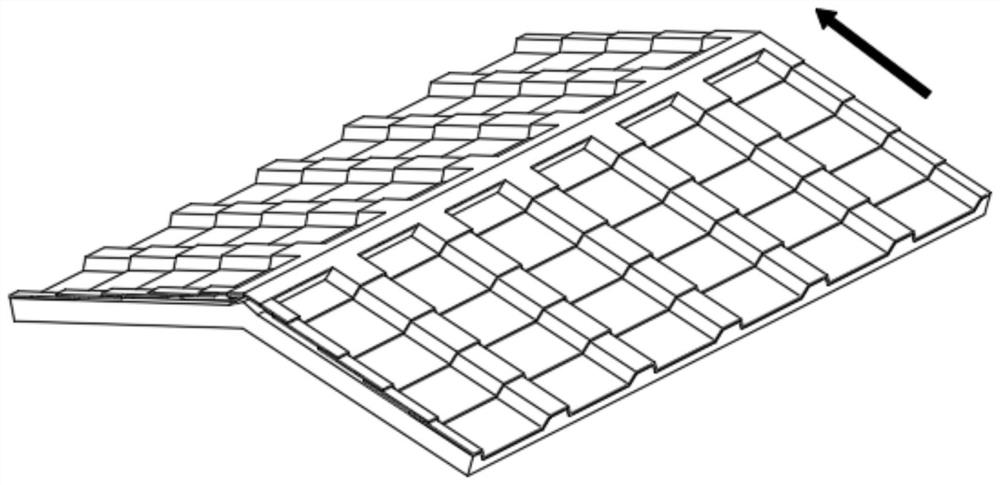

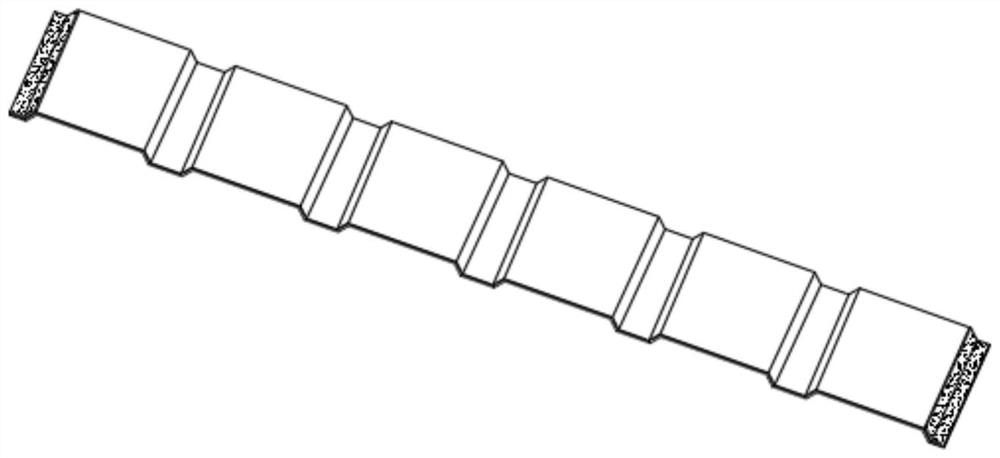

[0038] A color steel tile roof waterproof membrane filming method, such as Figure 1 to Figure 3 Shown:

[0039] The specific steps of the film sticking method include:

[0040] S1, clean and polish the surface of the color steel tile roof, and then use a powerful fan to remove the dust to ensure that the surface of the color steel tile roof is smooth and free of debris, sharp protrusions and dirt;

[0041] S2, according to the actual size of the waterproof membrane, arrange the size on the surface of the color steel tile roof, mark it as a coordinate line, and use it as a control reference line for the laying of the waterproof membrane;

[0042] S3, start coating three adhesive tapes parallel to the ridge along one end of the color steel tile roof parallel to the ridge.

[0043] S4, starting from one end of the color steel tile roof parallel to the ridge, unwinding along the preset reference line, rolling along the long side of the waterproof membrane, and then cutting acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com