Composite material reinforcing special-shaped mortise and tenon self-fastening-type duct pieces for underground pipe galleries

A composite material, underground pipe gallery technology, applied in underwater structures, buildings, artificial islands, etc., can solve the problems of concrete disintegration, easy corrosion, short service life of underground pipe gallery, etc. The effect of prolonging the maintenance and replacement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

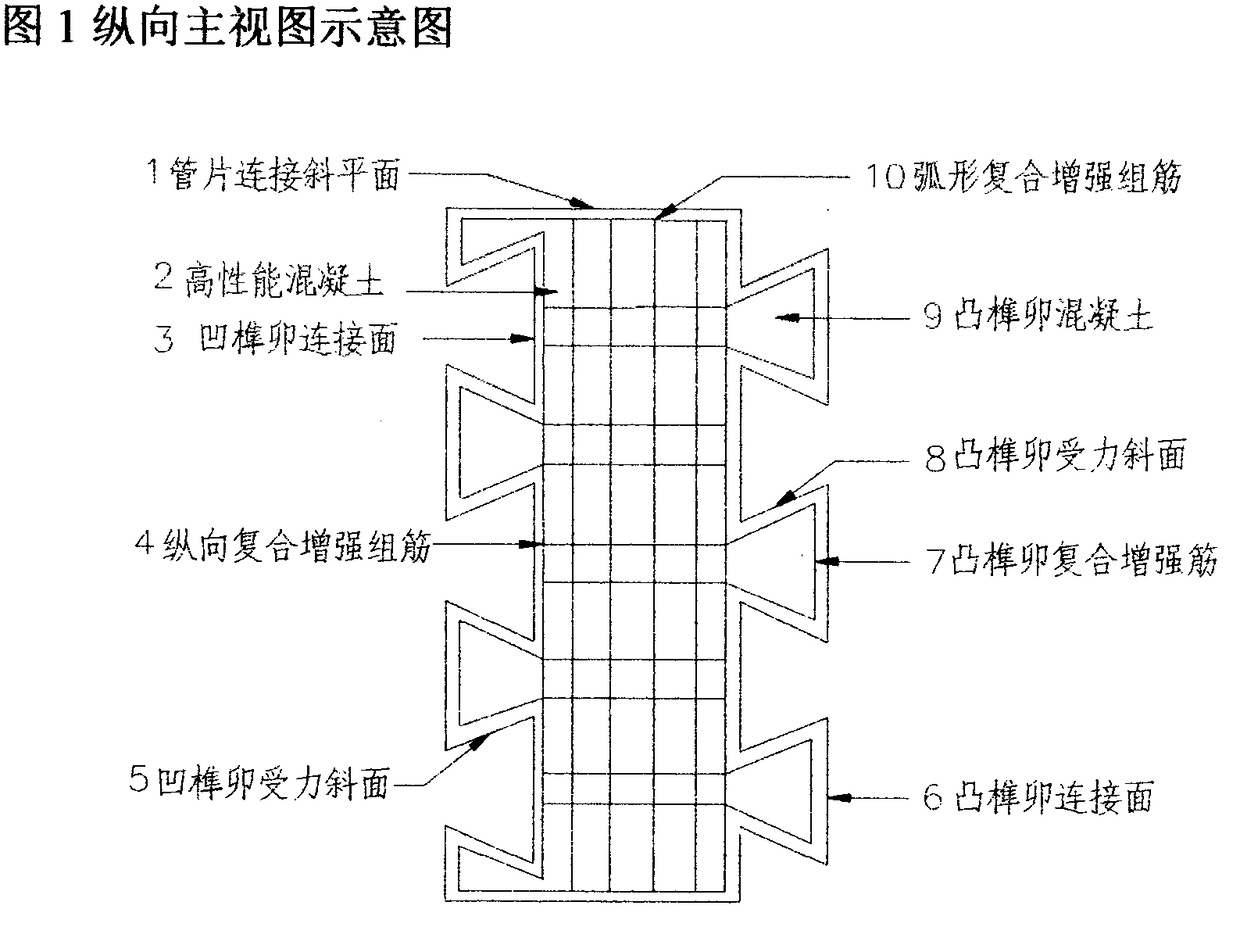

[0010] Referring to the accompanying drawings, a composite material reinforced special-shaped mortise and tenon self-fastening underground pipe gallery segment of the present invention is further described: the composite material tendon reinforced underground pipe gallery main body segment is characterized in that it includes the segment Connection inclined plane (1), high-performance concrete (2), tenon-tenon joint surface (3), longitudinal basalt fiber composite reinforcement (4), concave tenon-tenon stress slope (5), tenon-tenon joint surface ( 6) Consisting of tenon-mortise and tenon-tenon composite material reinforcement (7), tenon-mortise and tenon-tenon stress slope (8), convex tenon and tenon concrete (9), and arc-shaped composite material reinforcement (10), a composite material of the present invention The manufacturing process of the reinforced special-shaped mortise and tenon self-fastening underground pipe gallery segment is simple. The specific process is: process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com