Shoveling liquid and preparation process thereof

A preparation process and clear liquid technology are applied in the field of scavenging liquid and its preparation technology, which can solve problems such as unfavorable environmental protection, achieve good application effect, prevent rusting, and improve the effect of scavenging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

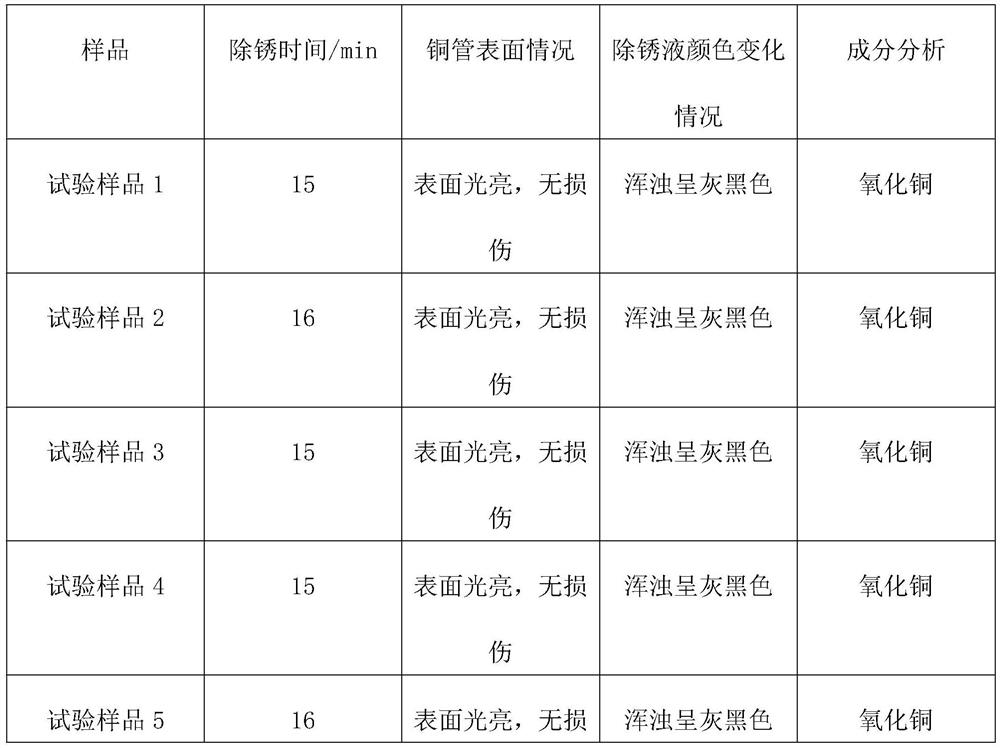

Examples

Embodiment 1

[0037] Embodiment 1: A kind of shoveling liquid, each component and its corresponding parts by weight are as shown in Table 1, and are prepared through the following steps:

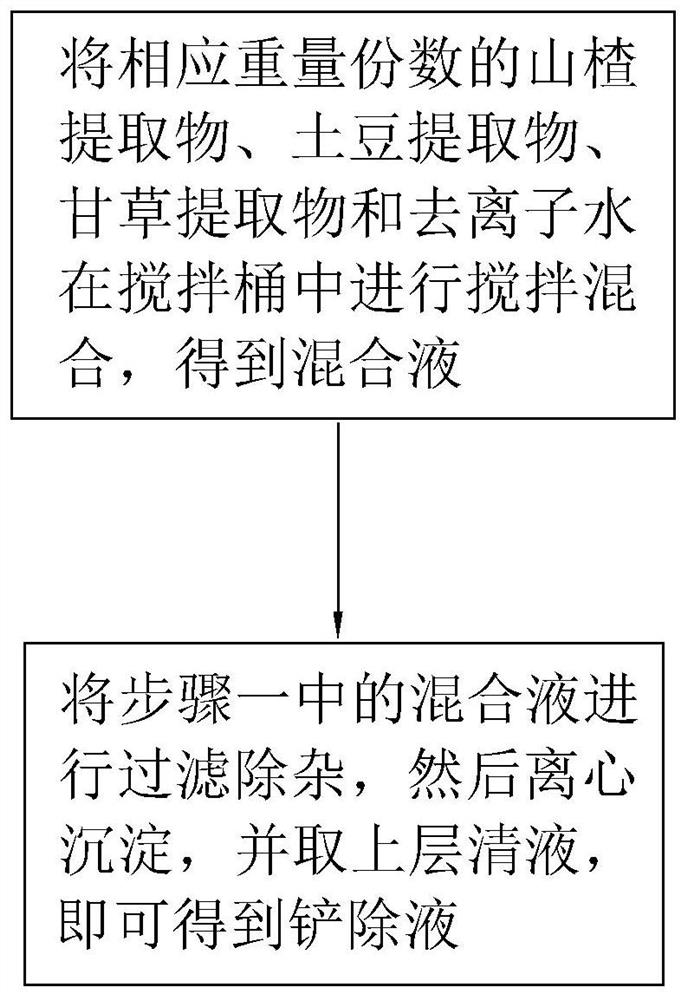

[0038] Step 1, mixing the raw materials, stirring and mixing the hawthorn extract, potato extract, licorice extract and deionized water in corresponding parts by weight in a mixing tank, the stirring speed is 50r / min, and the time is 30min, to obtain a mixed solution;

[0039] Step 2, filter to remove impurities, filter the mixed liquid in step 1 with a 200-mesh screen to remove impurities, then centrifuge to precipitate, and take the supernatant to obtain the eradicated liquid.

[0040]Note: The hawthorn extract in step 1 is specifically obtained by the following extraction steps: take the hawthorn raw material, slice it, then soak it in 3 times the amount of 80% ethanol solution, heat it to 65°C for 2 hours, and filter to obtain the primary extraction liquid and filter residue; after concentrating the i...

Embodiment 2-8

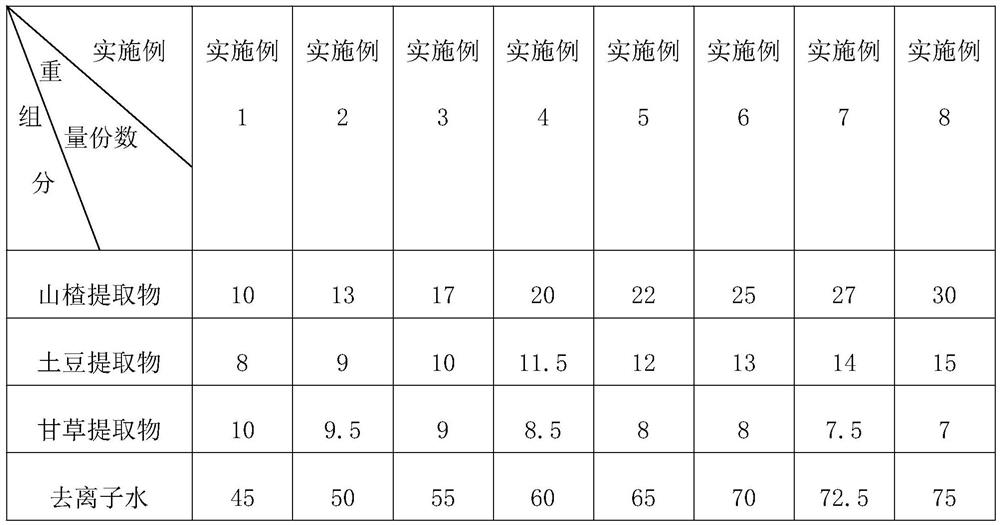

[0043] Embodiment 2-8: A shoveling solution. The difference from Embodiment 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0044] Each component and parts by weight thereof in table 1 embodiment 1-8

[0045]

Embodiment 9

[0046] Embodiment 9: A kind of eradicating liquid, the difference with embodiment 1 is that step 1 is specifically set as, mixing raw materials, the corresponding parts by weight are 10 parts of hawthorn extract, 8 parts of potato extract, 10 parts of licorice extract, 6 parts of cypress leaf extract and 45 parts of deionized water were stirred and mixed in a mixing tank at a stirring speed of 50 r / min for 30 min to obtain a mixed solution. The cypress leaf extract was purchased from Xi'an Qiancao Biotechnology Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com