Vegetable greenhouse with ventilation and buffer functions

A technology for vegetable greenhouses and greenhouses, which is applied in the field of improving the ventilation system of vegetable greenhouses, can solve the problems of easy introduction of pests and diseases, easy deflection of the winder, and difficulty in ventilation, so as to reduce the risk of pests and diseases, facilitate manual operation, and eliminate the use of pesticides. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

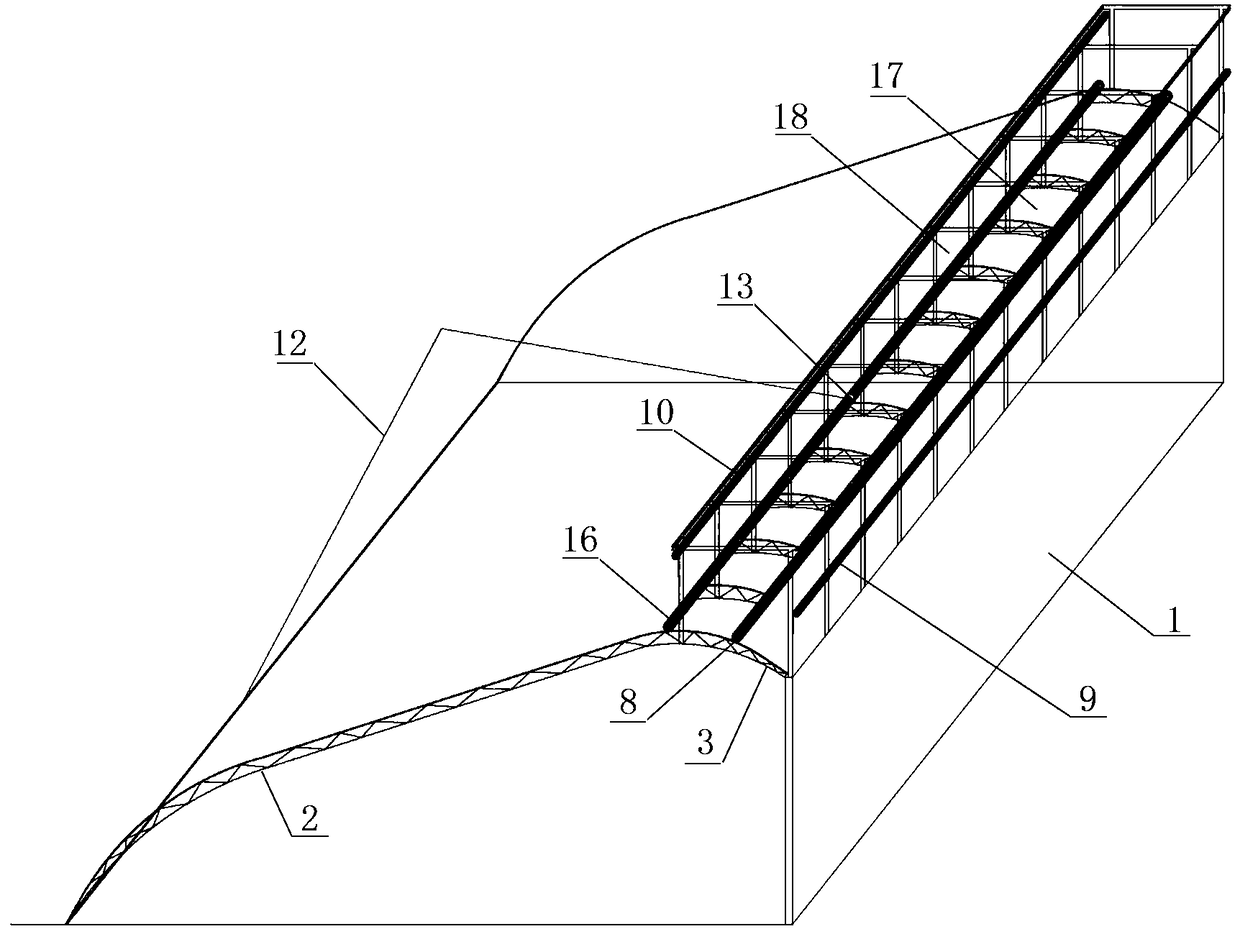

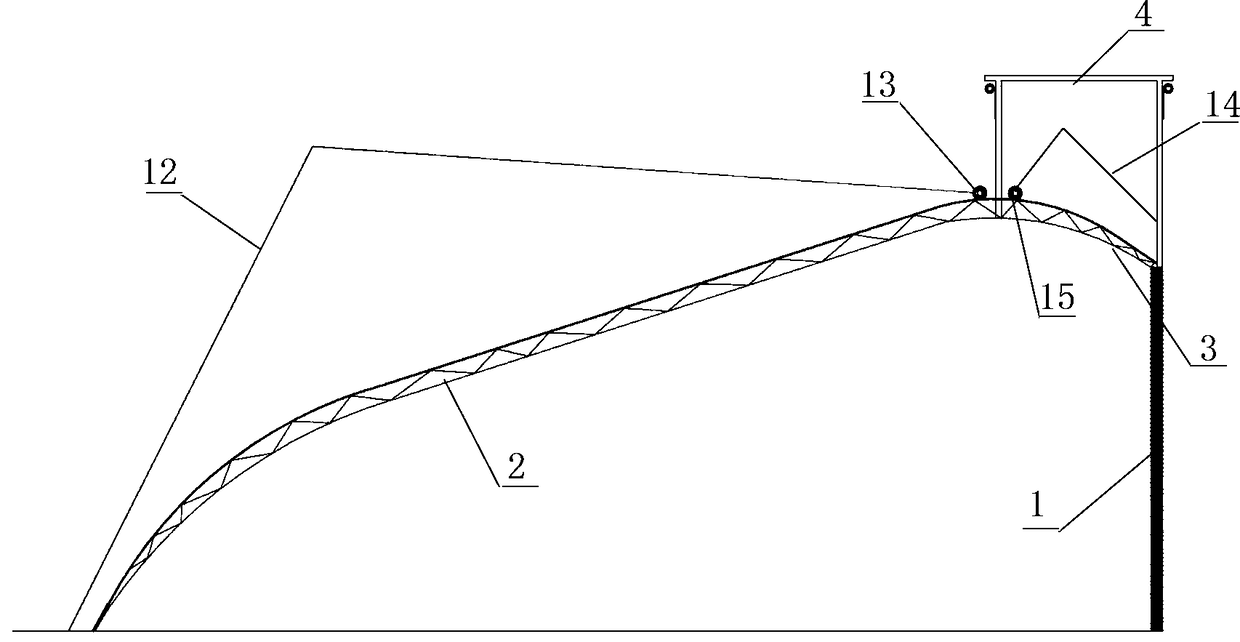

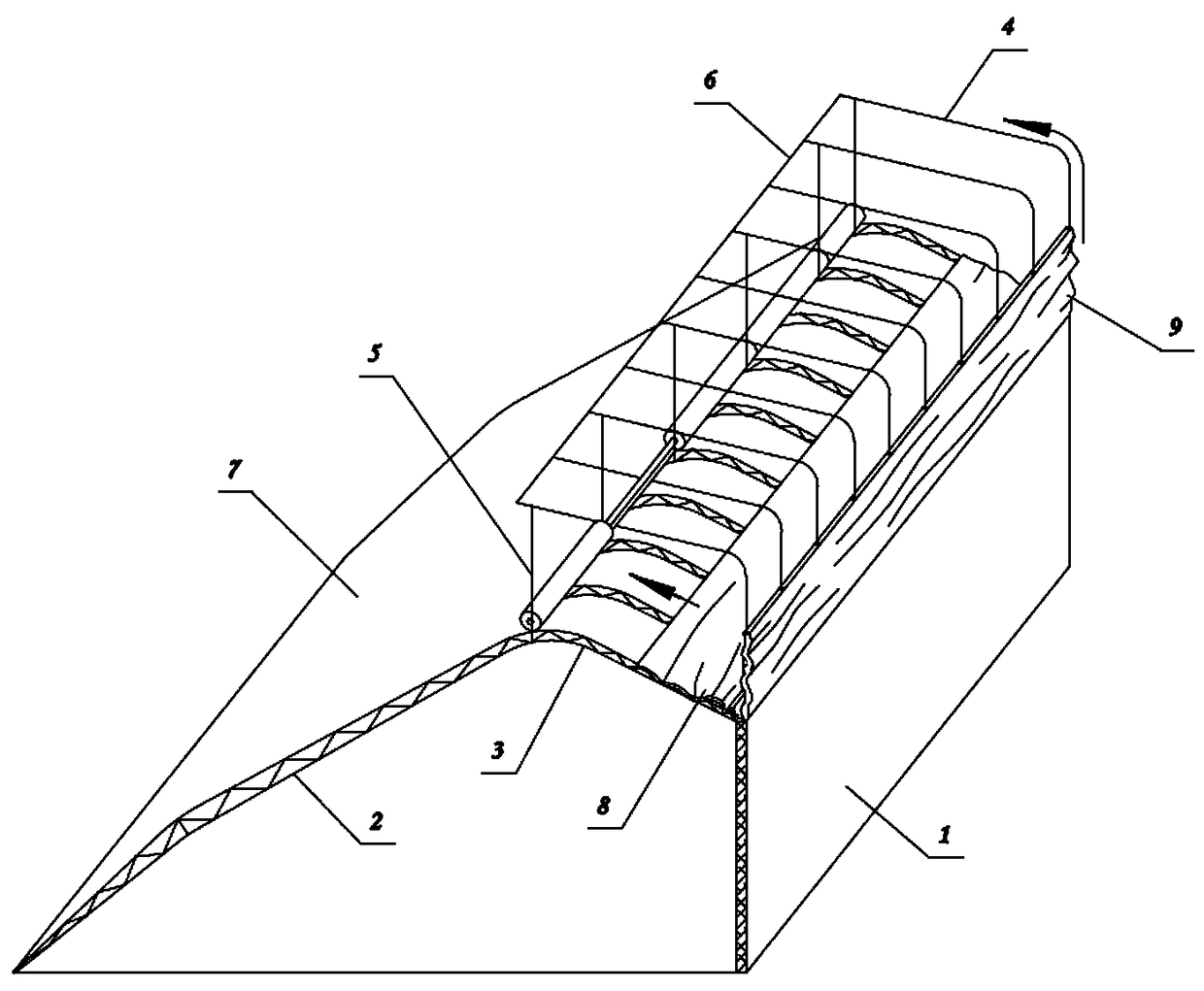

[0023] Embodiment 1: A kind of vegetable greenhouse with ventilation buffer function, see figure 1 , image 3 with Image 6 As shown, it includes the rear wall 1 of the greenhouse, the skeleton of the greenhouse and the film 7 of the greenhouse. As well as the necessary structures or components such as greenhouse entrances, doors and fixed ropes (not shown in the picture).

[0024] Such as figure 2 As shown, the thermal insulation rewinding system is prior art equipment, including the thermal insulation rewinding system folding rod 12, the thermal insulation rewinding system rewinding motor 13 and the thermal insulation quilt 16, and the thermal insulation quilt 16 is covered on the outside of the greenhouse film 7. One end of the folding rod 12 of the heat preservation rewinding system is fixed on the ground, and the other end is installed with a rewinding motor 13 of the heat preservation rewinding system. Rewind and unwind. In like manner, the wind-releasing system is...

Embodiment 2

[0033] Embodiment 2: On the basis of Embodiment 1, an insect-proof net is installed on the upper side between each pillar 5 on the front side of the ventilation support. The insect-proof net is a roller shutter type, and its upper end is provided with a curtain shaft or a card slot. The air inlet of the ventilation structure is equipped with an anti-insect attachment, which can effectively isolate pests from entering the greenhouse and reduce the risk of vegetables in the greenhouse being attacked by diseases and insect pests, so as to minimize or even eliminate the use of pesticides and provide support for the cultivation of green and environmentally friendly vegetables.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com