Guide bar

A technology of guide rods and protruding parts, applied in the field of guide rods, can solve the problems of increasing friction, increasing wear of guide rod saw chains, increasing lateral movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

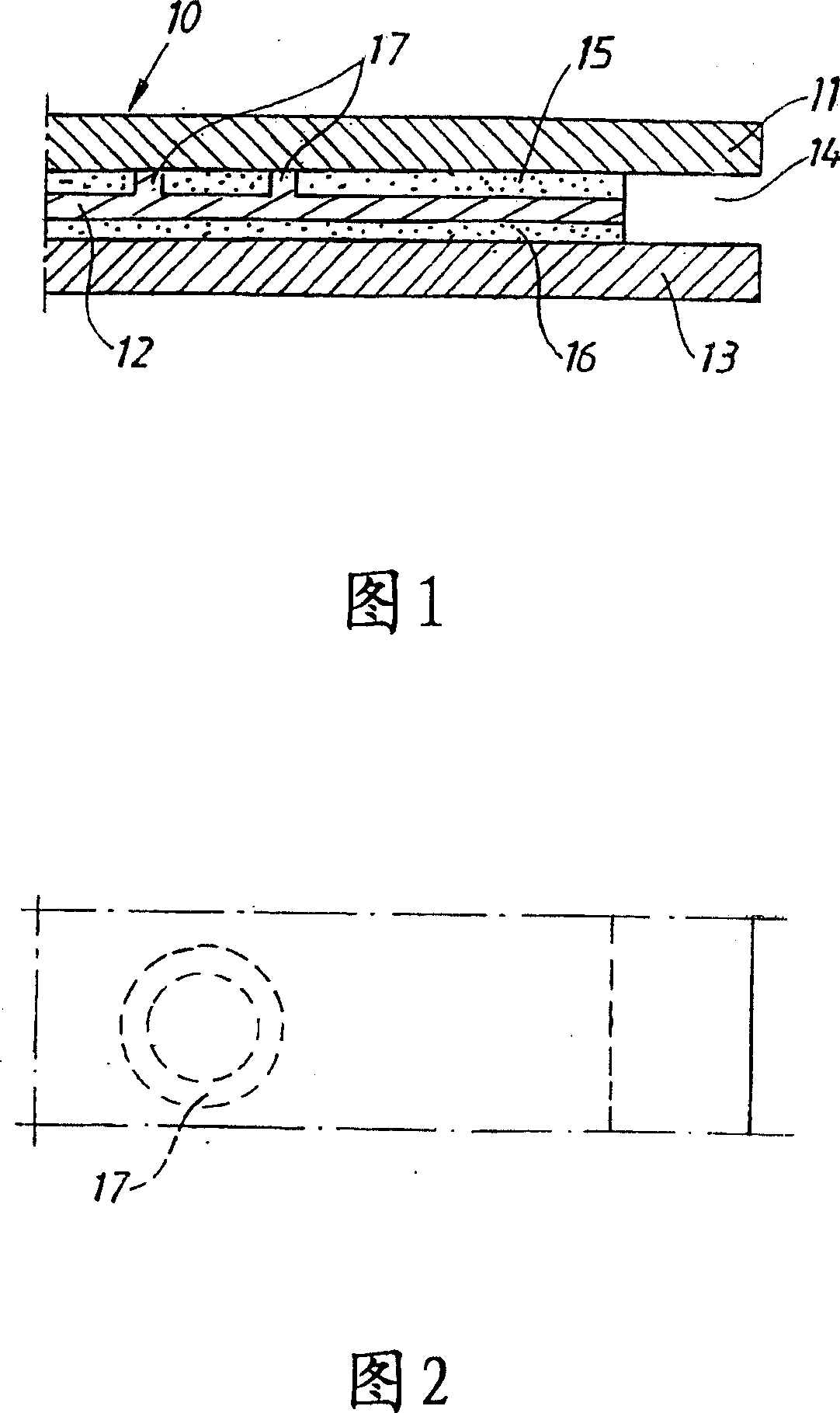

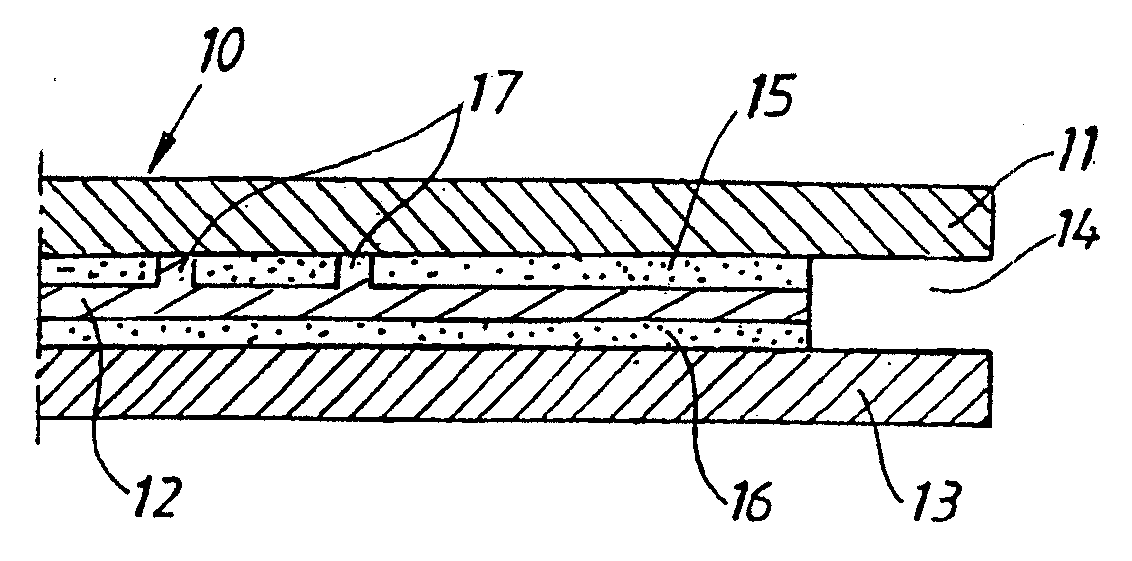

[0025] The guide rod 10 comprises three layers 11 , 12 , 13 . The first layer 11 and the third layer 13 are identical in shape, while the middle layer 12 is shorter and slightly smaller in width. When these three layers 11 , 12 , 13 are put together, a groove 14 is defined around the guide rod 10 due to the smaller size of the middle layer 12 . Slot 14 is used for a saw chain, not shown.

[0026] The guide rod 10 comprises three different layers 11 , 12 , 13 bonded together by two layers of adhesive material 15 , 16 acting on almost the entire surface in contact with each other.

[0027] The intermediate layer 12 is provided with a plurality of protrusions 17 . When the layers are brought together, the protrusion 17 creates a slot between the layers. The protrusion 17 controls the width of the slot and thus the thickness of the adhesive layer so that the maximum strength of the two bonds is achieved. The constant and precise width of this slot is important to ensure that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com