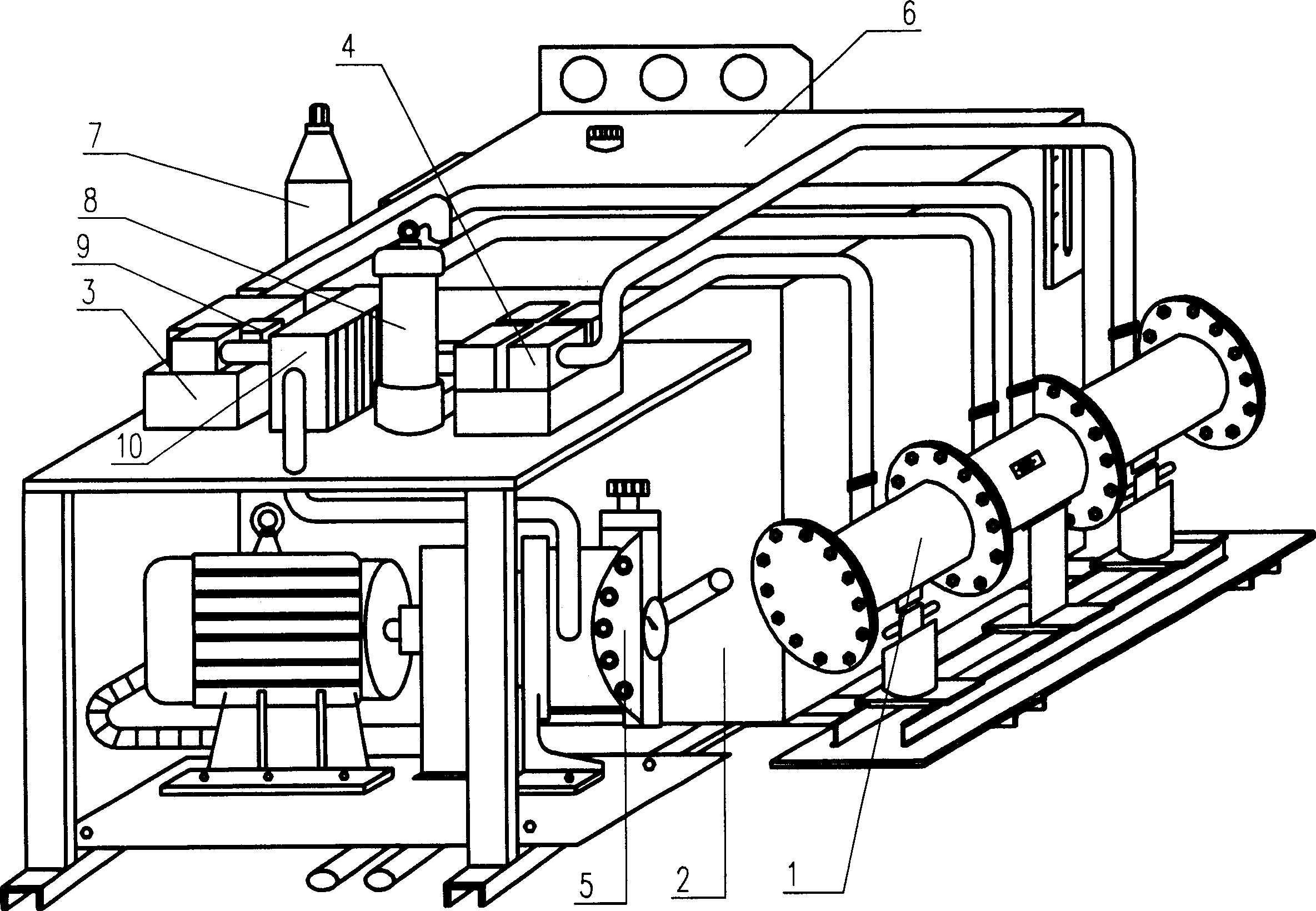

Boosting water injector for oil field

A technology for oil fields and booster cylinders, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., to achieve the effect of improving service life, reducing the requirements for installation piston deviation, and having broad development prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

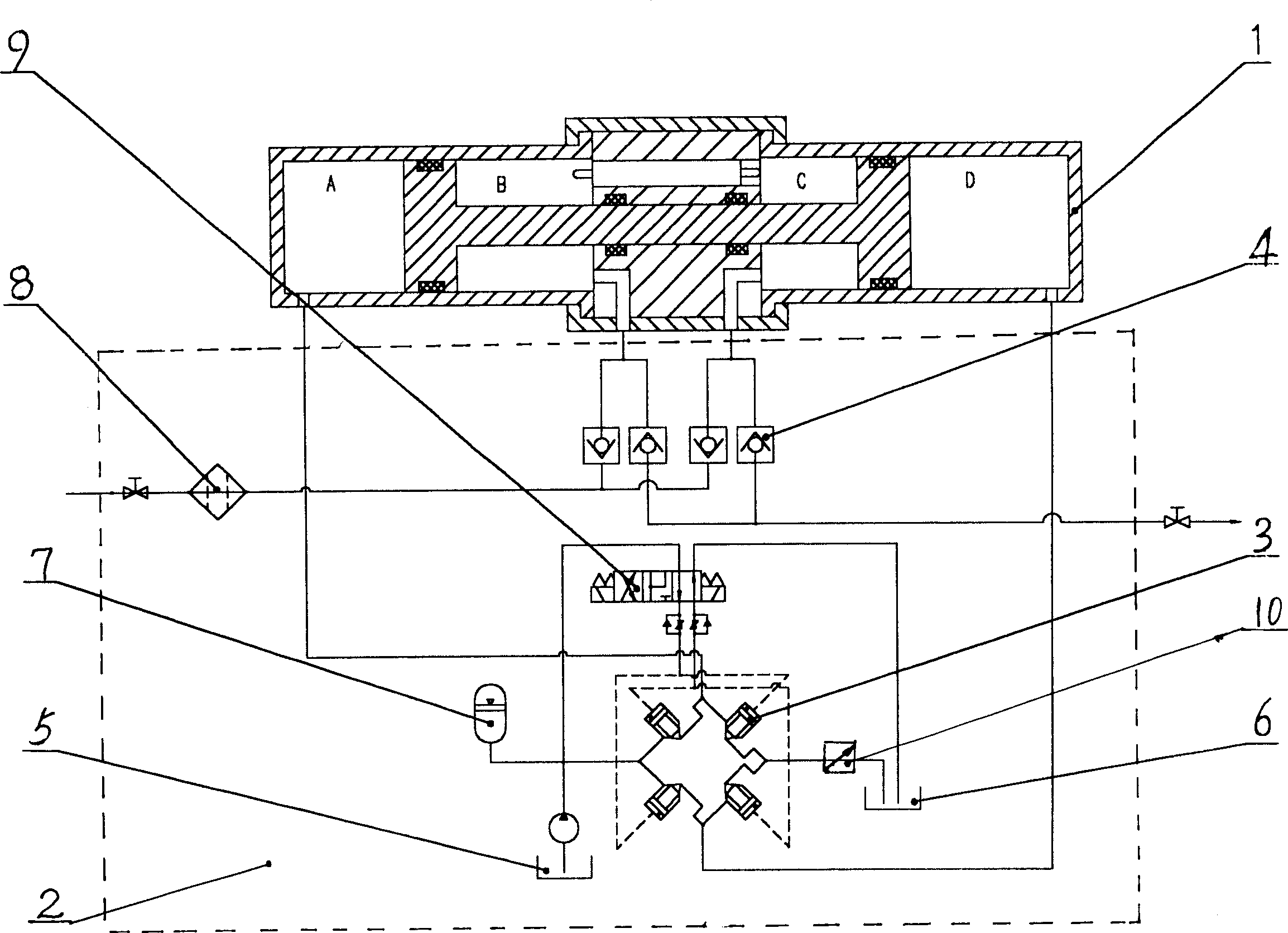

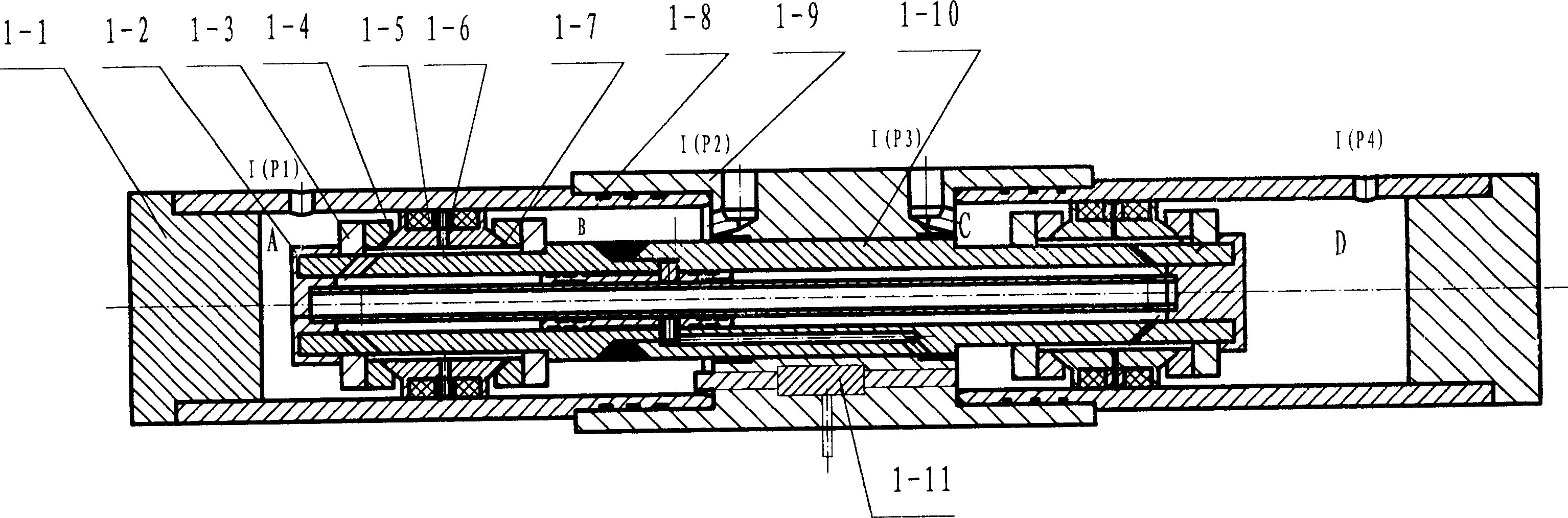

[0018] Embodiment 1, using the present invention to use the pressure of the water itself and the pressure of the circulating oil to pressurize the water injection through the booster cylinder of the water injection device, the piston of the booster cylinder adopts a spherical plug body self-positioning anti-deflection piston structure, and the piston The reversing adopts the piston touch-sensitive reversing mechanism and the oil field pressurized water injection device adopts the ball valve structure of the circulating oil oil valve group. The incoming water pressure is 11MPa, and the pressurized water injection device in the oil field injects water into the formation, and the outlet pressure of the high-pressure water injection is 26MPa, which can continuously inject water for 5 months. The water injection work meets the water injection requirements. The energy is greatly saved, the cost is reduced, the water injection operation is convenient, and it is easy to popularize and...

Embodiment 2

[0019] Embodiment 2, using the present invention to use the pressure of the water inlet itself and the pressure of the circulating oil to pressurize the water injection through the booster cylinder of the water injection device, the piston of the booster cylinder adopts an oval plug body self-positioning and anti-deflection piston structure, and the piston of the booster cylinder The reversing adopts the piston touch-sensitive reversing mechanism and the oil field pressurized water injection device adopts the ball valve structure of the circulating oil oil valve group. The incoming water pressure is 15MPa, and the pressurized water injection device in the oil field injects water into the formation, and the outlet pressure of the high-pressure water injection is 27MPa, which can continuously inject water for 4 months without failure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com