High-low pressure zone separation mechanism for vortex compressor

A technology of scroll compressor and isolation mechanism, which is applied in the direction of rotary piston machinery, machine/engine, rotary piston pump, etc., and can solve the problems of installation error, installation error, and defect of rotating sheet 7a and fixed sheet 8a

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

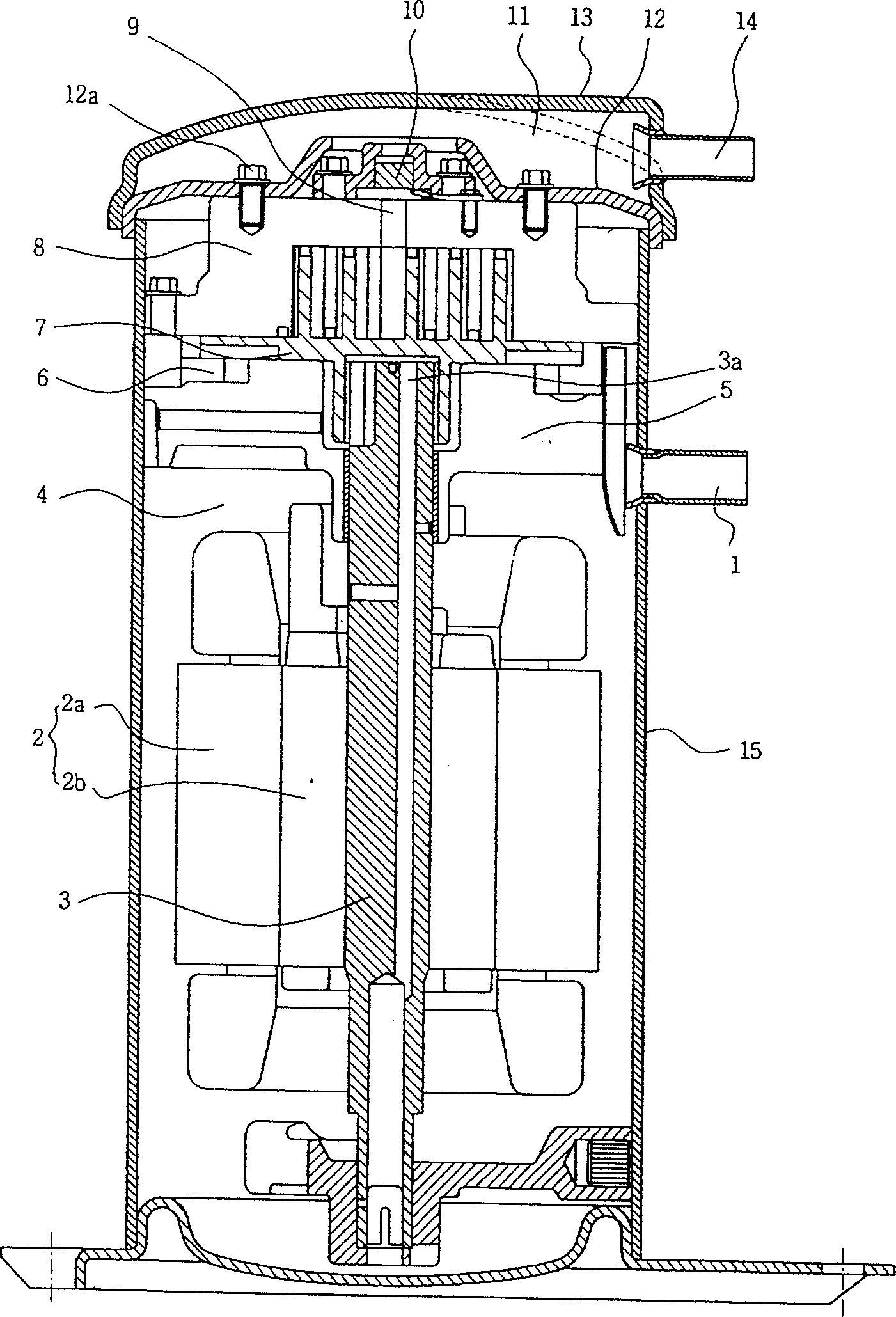

[0041] Attached below Figure 5 and the specific embodiment The high and low pressure area isolation mechanism of the scroll compressor of the present invention will be further described in detail.

[0042] Isolation frame 29 is oblate cylindrical, and the outer peripheral surface of flat cylindrical isolation frame 29 is in close contact with the inner peripheral surface of airtight housing 15, and the upper plane of flat cylindrical isolation frame 29 is screwed with fixed scroll 8. The lower plane is connected and in close contact. There is an air suction hole 29a in the isolation frame 29. The air suction hole 29a communicates with the suction chamber 4 and the suction pipe 1 below, and communicates with the compression zone of the fixed scroll 8 and the movable scroll 7 above.

[0043]In the technical scheme of the present invention, instead of installing the upper partition 12 provided by the traditional scroll compressor in order to separate the high-pressure fluid and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com