Automatic cutting device for sewing machine

A sewing machine and driving device technology, applied in the field of sewing machines, can solve the problems of large volume, complex overall structure, power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Please refer to figure 1 To Fig. 7, the utility model is described in detail.

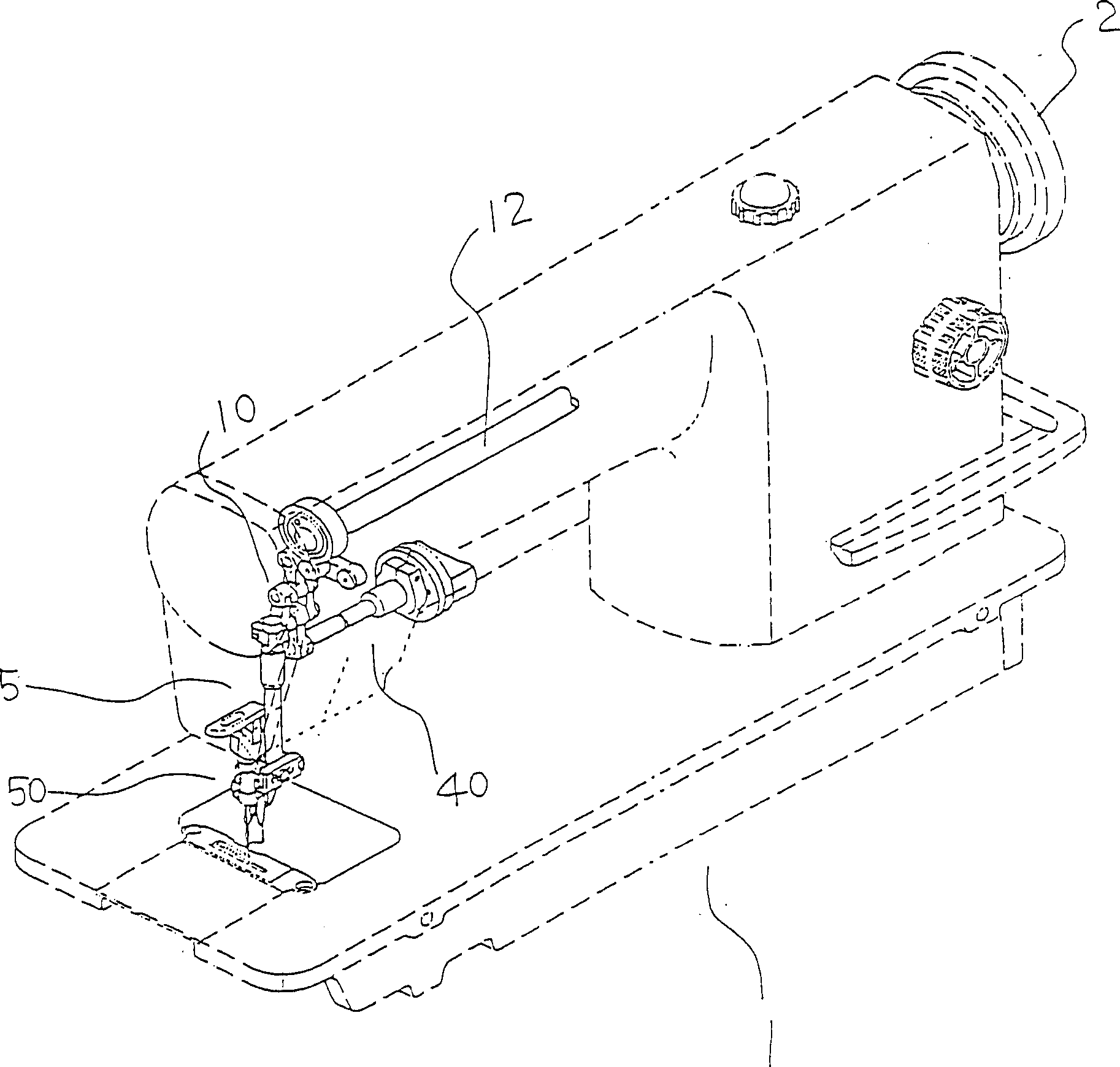

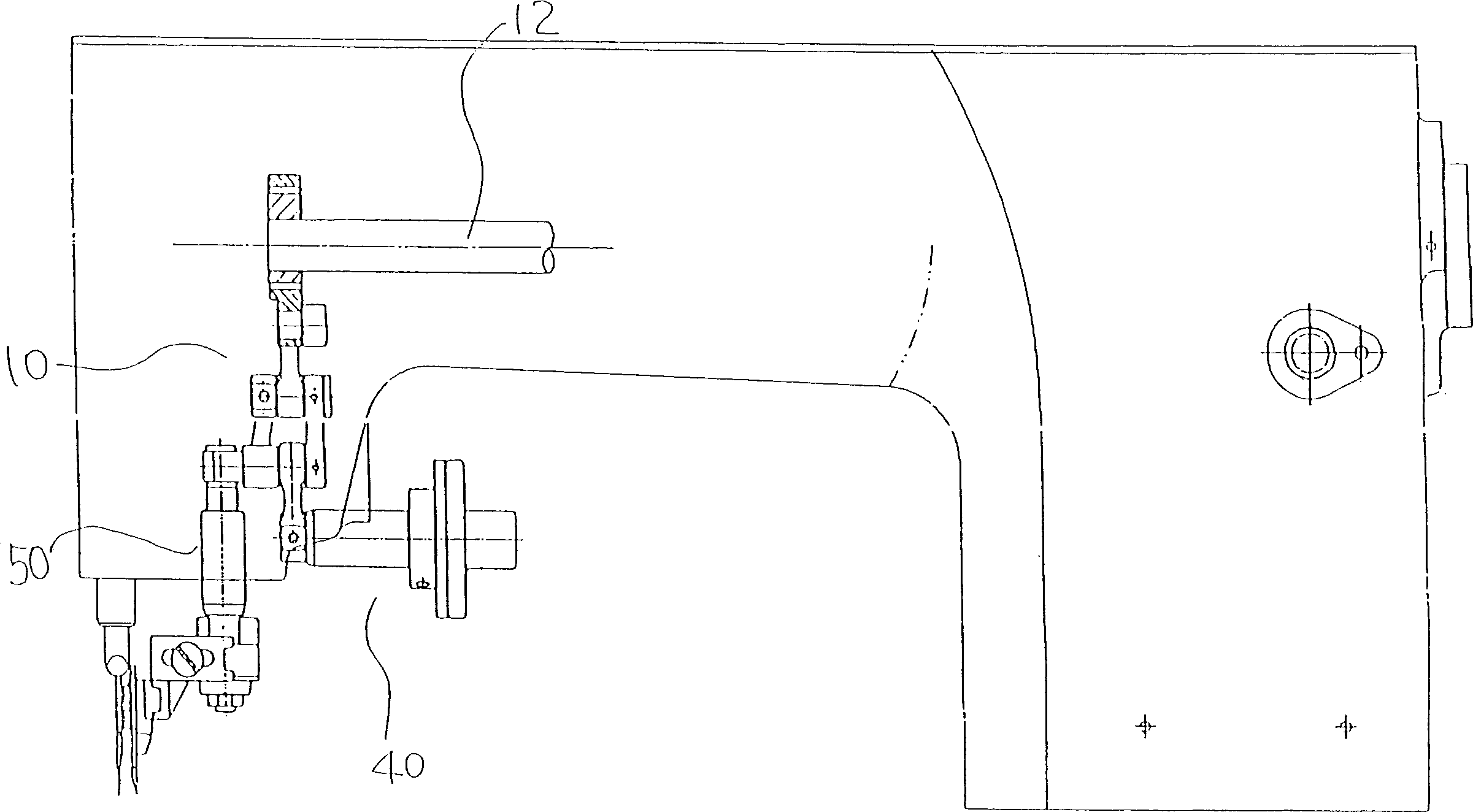

[0056] The automatic cloth cutting device 5 of sewing machine of the present invention, as figure 1 and figure 2 As shown, a driving device 10, a control device 40 and a cutter moving device 50 are included.

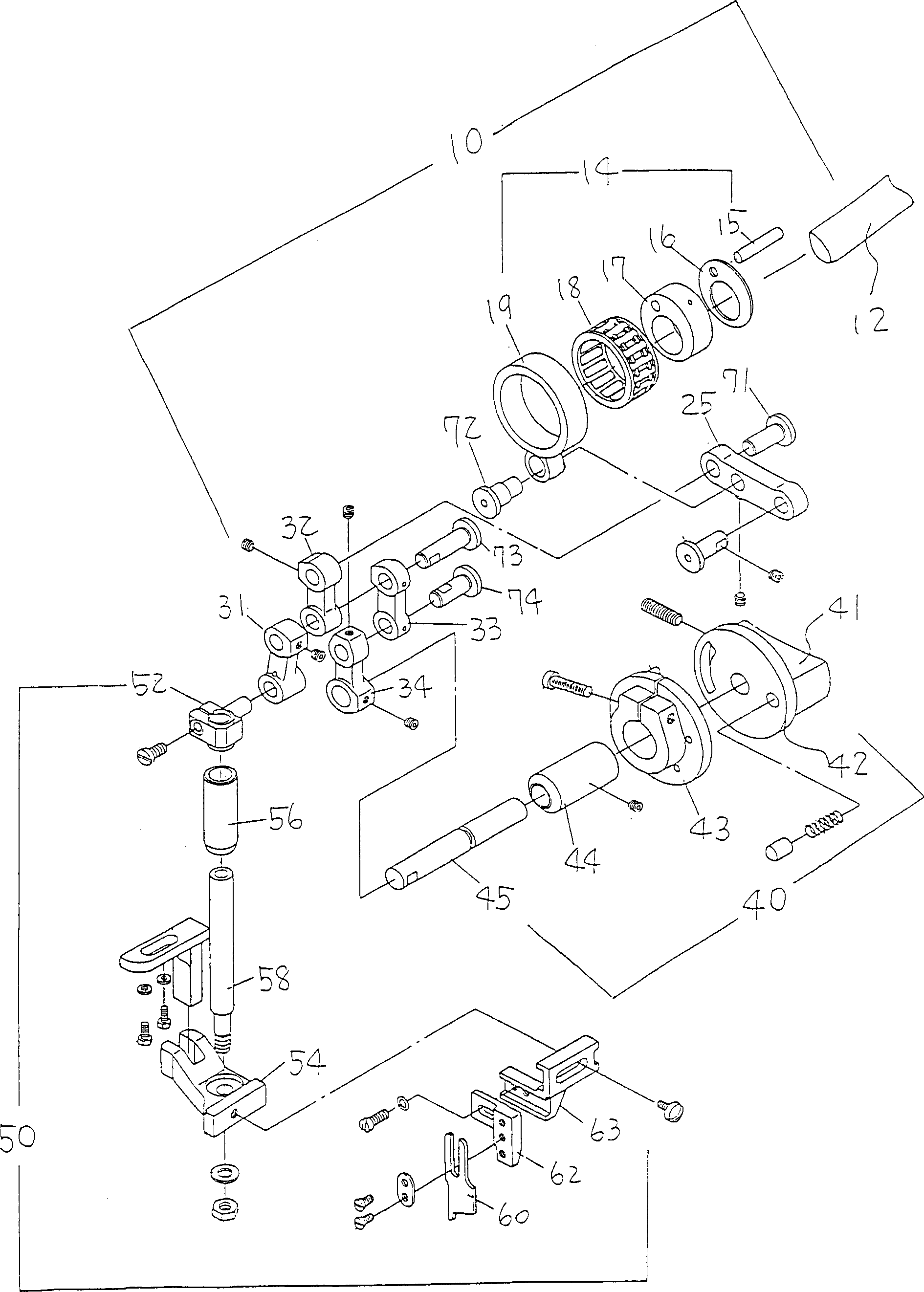

[0057] image 3It is an exploded view of the automatic cloth cutting device of the sewing machine according to the present invention. The driving device 10 mainly includes a driving shaft 12 , an eccentric wheel set 14 , a connecting rod set 30 , and a fixed rocker 25 . One end of the drive shaft 12 is connected to a pulley 2 to drive the action of the entire sewing machine 1, such as cloth cutting action and single-needle sewing, while the other end is inserted into the hollow of the eccentric wheel set 14 to drive the entire cloth cutting device. action. The composition of the eccentric wheel group 14 is that the gasket 16 is connected and fixed to the eccentric block 17 by th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap