Needle rod driving mechanism

A driving mechanism and needle bar technology, which is applied to the mechanism of embroidery machines, embroidery machines, sewing machine components, etc., can solve the problems of large space, large space, and increased load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

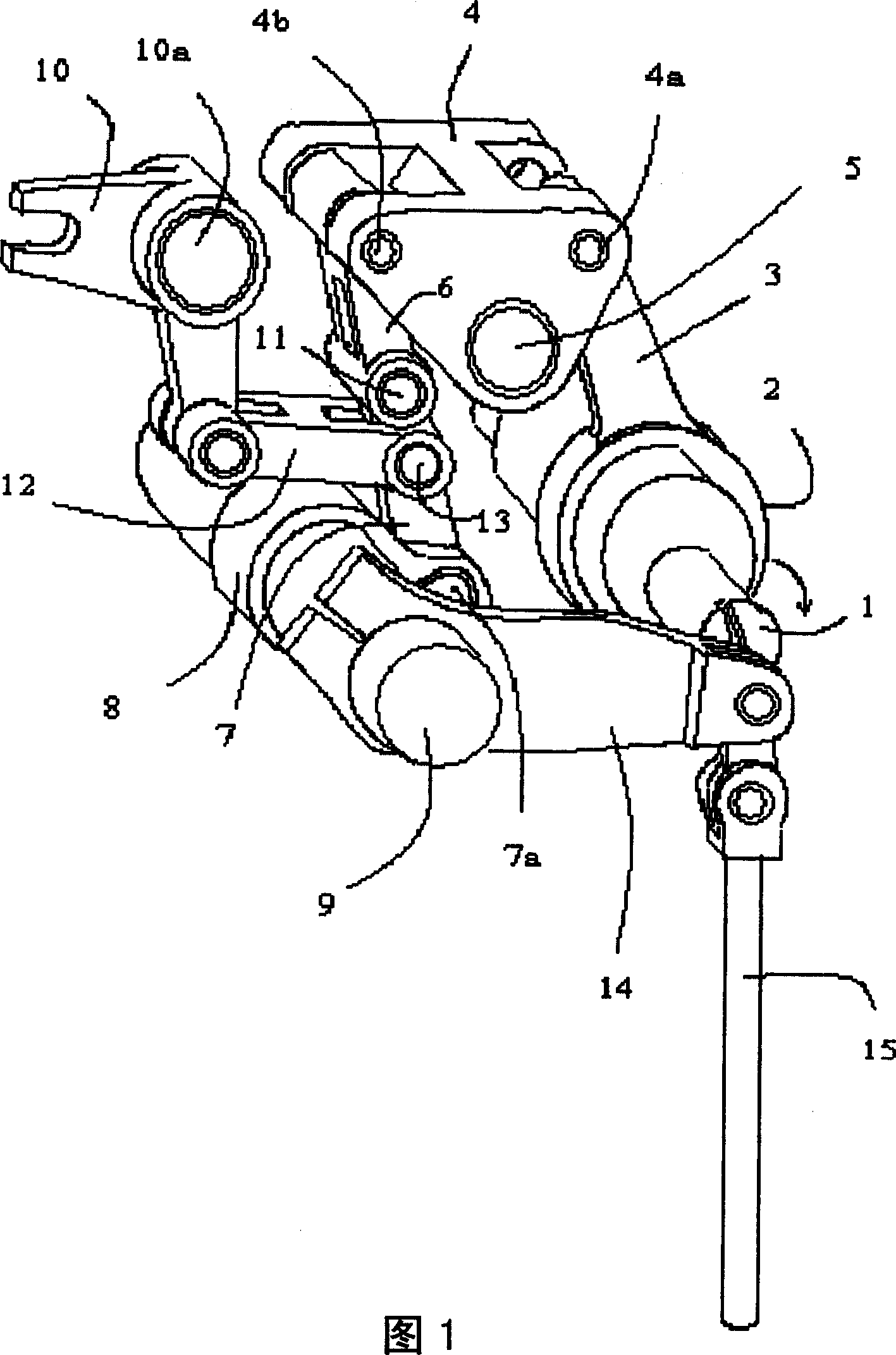

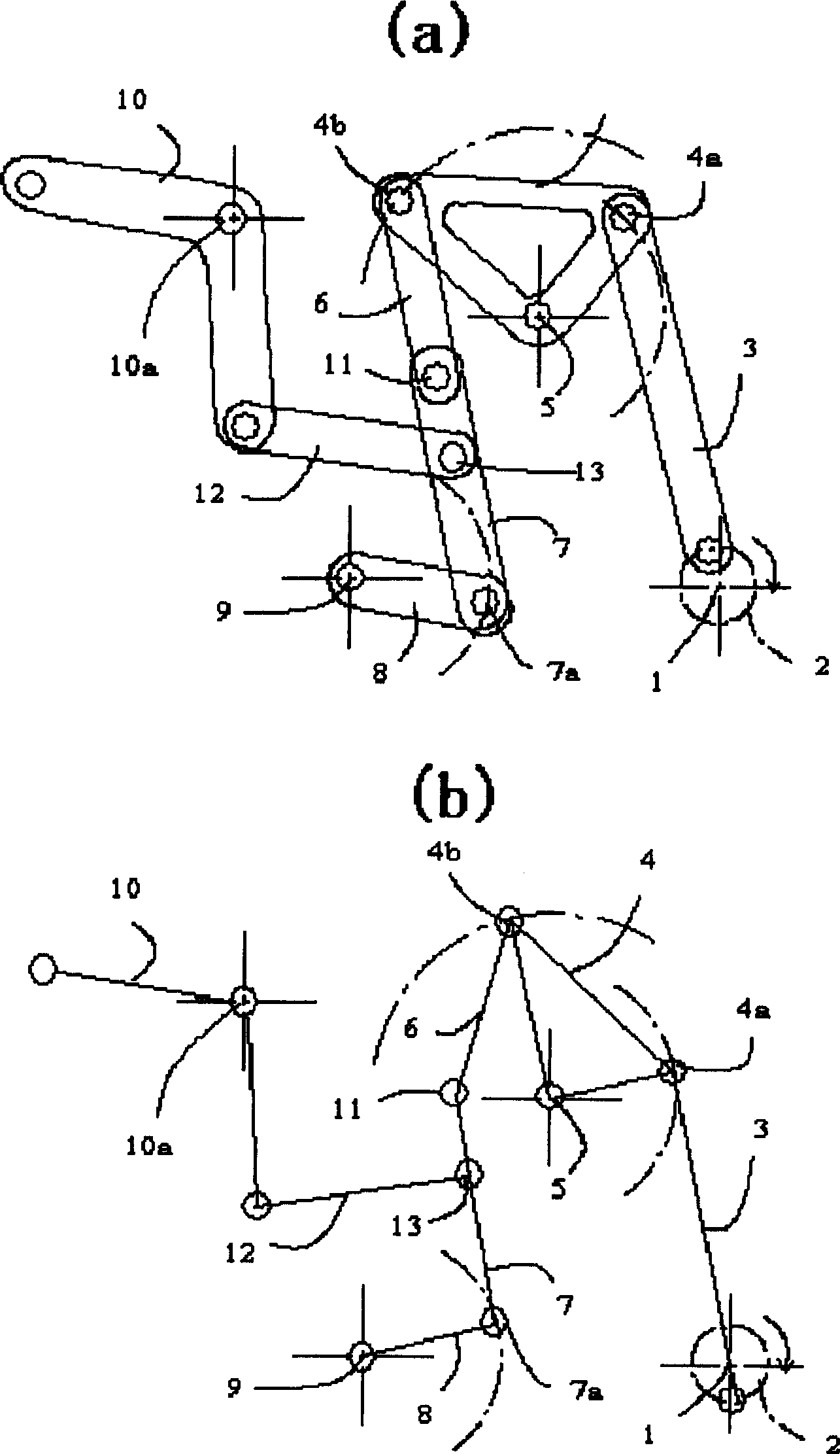

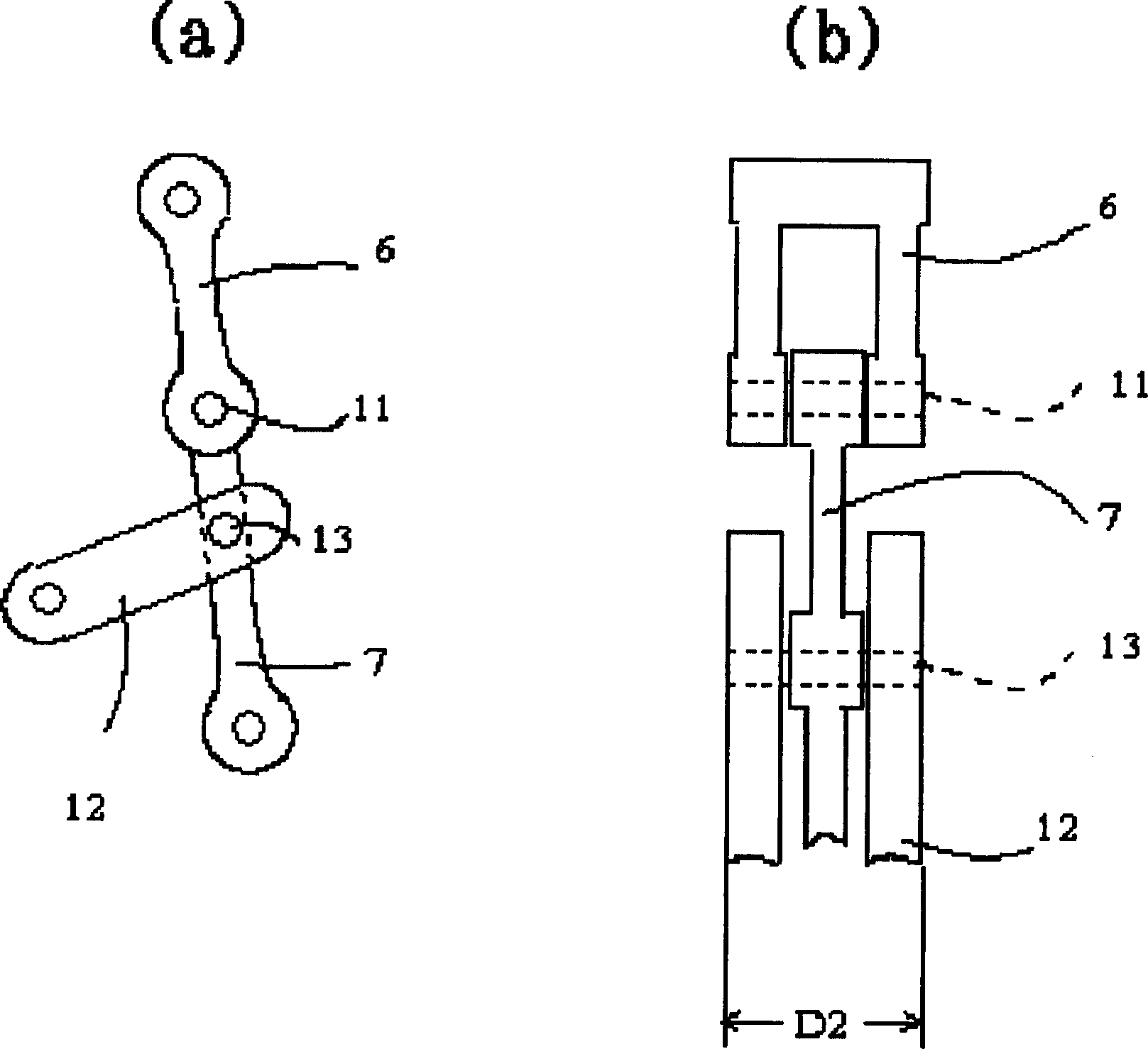

[0022] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0023] First, referring to Figure 1 and figure 2 (a) The structure of the needle bar drive mechanism of this embodiment will be described. The needle bar driving mechanism includes a sewing machine main shaft 1 and a needle bar driving shaft 9 rotatably supported on an unshown sewing machine frame, and a support shaft 5 and a lever shaft 10a respectively fixed on the sewing machine frame.

[0024] The eccentric cam 2 is fixed on the main shaft 1 of the sewing machine. The rocking arm 3 that one end is installed on this eccentric cam 2 with a shaft, rocks along with the movement of the sewing machine main shaft 1 . The middle part of the rocking body 4 is rockably supported on a support shaft 5 supported on the sewing machine frame. The rocking body 4 is rotatably connected to the other end of the rocking arm 3 at the first connecting point 4a at one end thereof, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com