Workpiece holding device

A technology for holding devices and workpieces, applied in the direction of work accessories, manufacturing tools, stone processing tools, etc., can solve the problems of enlarged diameter, deterioration of perforation accuracy, and increase of slack.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

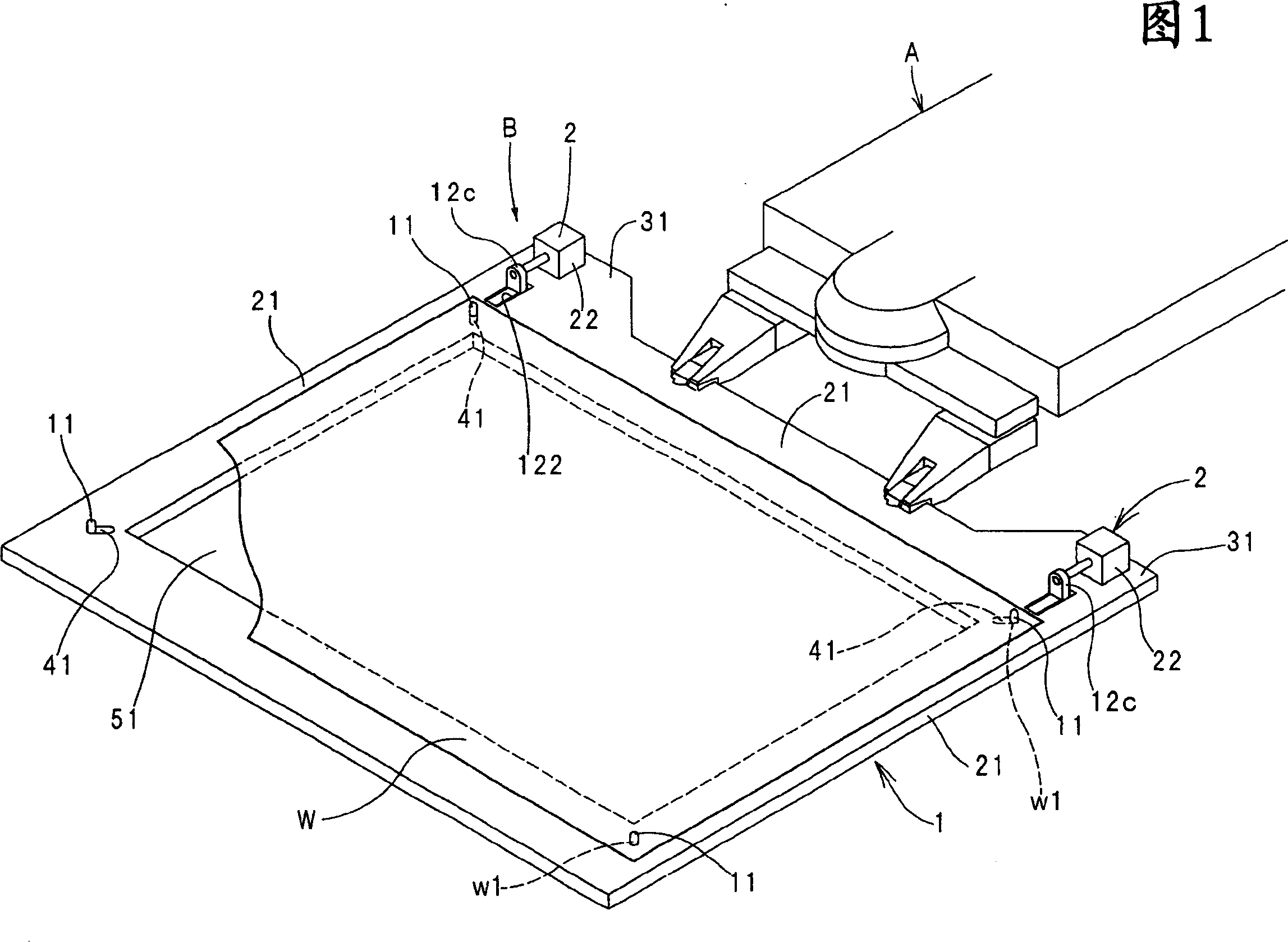

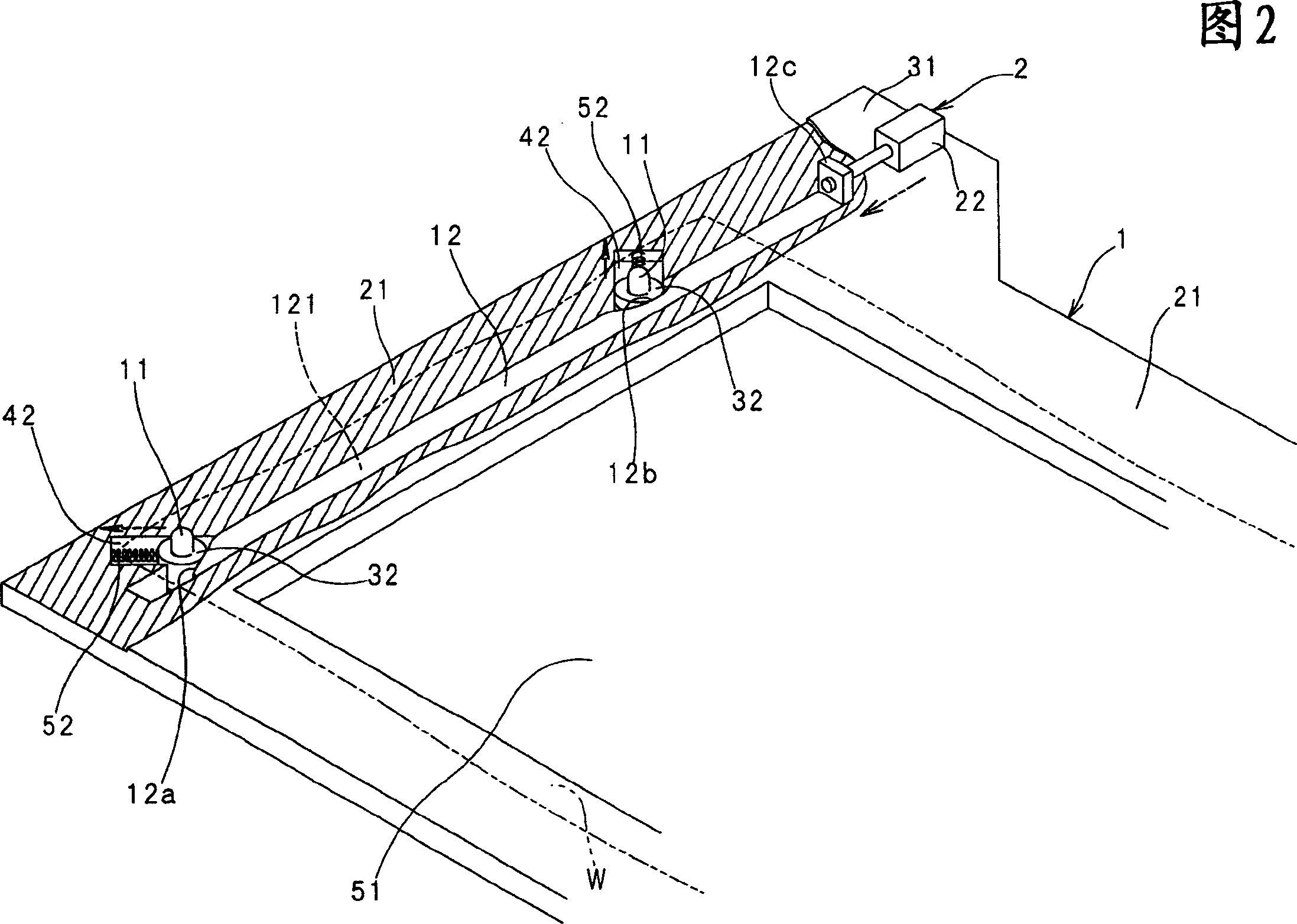

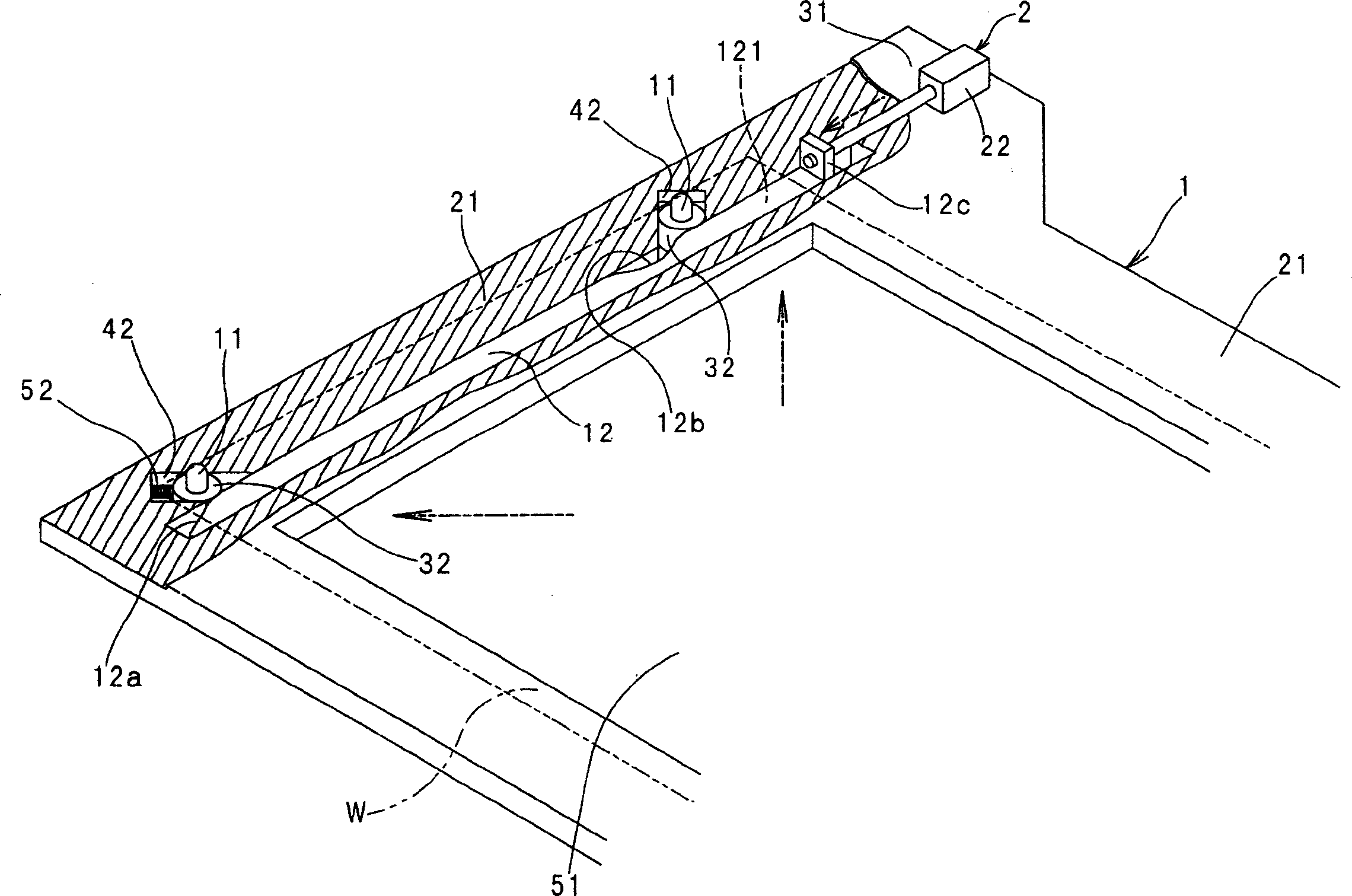

[0080] Embodiments of the workpiece holding device according to the invention will be described below. Figure 1~ Figure 5 The first embodiment is shown, and Fig. 6 to Fig. 11 show the second embodiment, Figure 12 ~ Fig. 15 shows the third embodiment, Fig. 16 shows the fourth embodiment, Fig. 17 ~ Fig. 21 shows the fifth embodiment, Figure 22 ~ Fig. 25 shows the sixth embodiment, Fig. 26 and Fig. 27 show the seventh embodiment, Fig. 28 and Fig. 29 show the eighth embodiment, Figure 30 ~ Figure 34 Showing the ninth embodiment, Figure 35 and Figure 36 A tenth embodiment is shown.

[0081] First, the first embodiment will be described. Symbol 1 is a workpiece support, and symbol B is a tension applying mechanism provided on the workpiece support 1 .

[0082] This tension applying mechanism B includes positioning pins 11 provided at positions corresponding to the four corners of the workpiece W so as to be movable in the diagonal direction of the workpiece W in the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com