Method for preparing composite hollow fibre membrane

A fiber membrane and composite membrane technology, used in the field of preparing composite hollow fiber membranes, can solve the problems of easy biodegradation (poor biological stability, narrow pH range, poor acid and alkali resistance, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

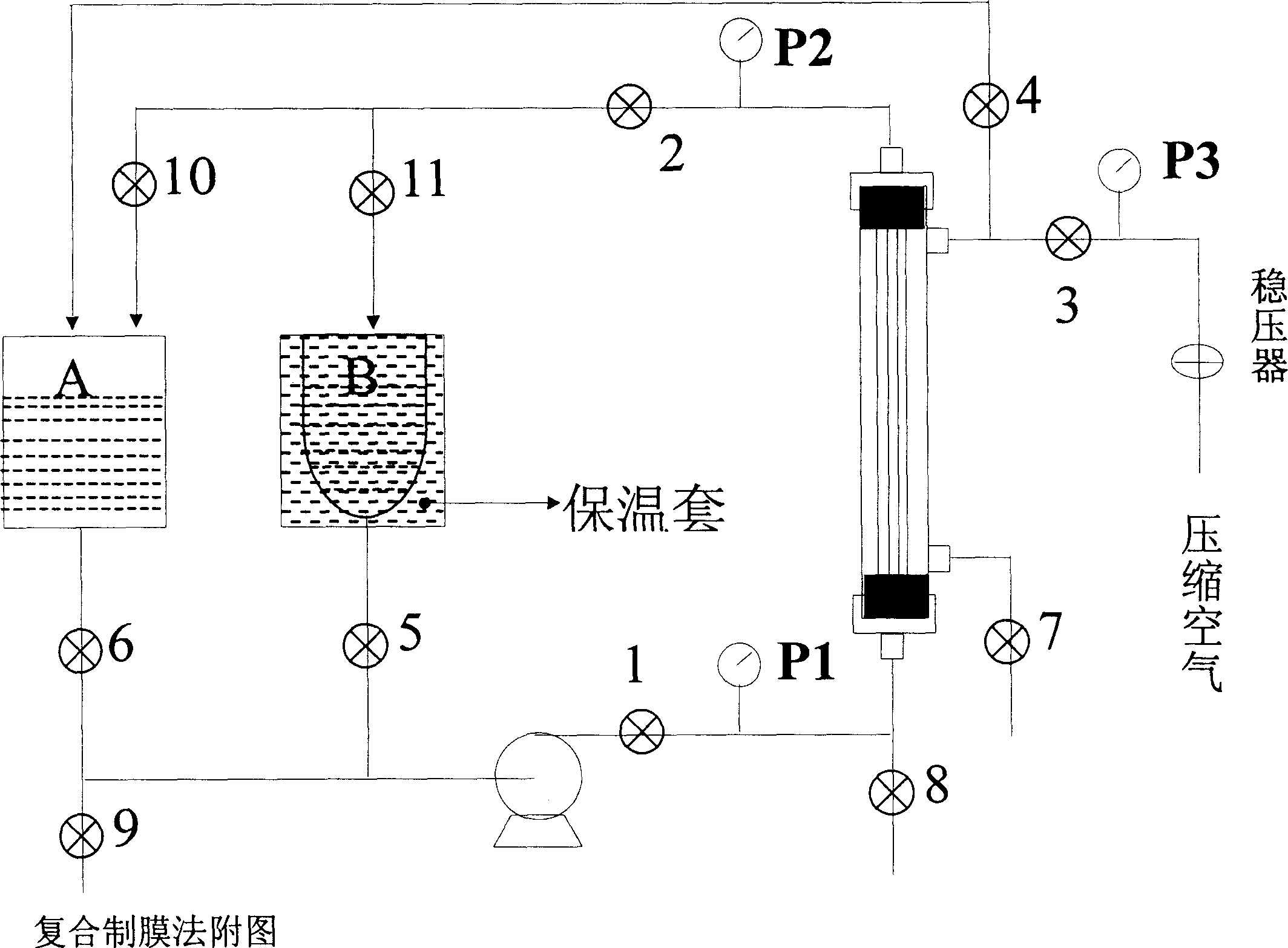

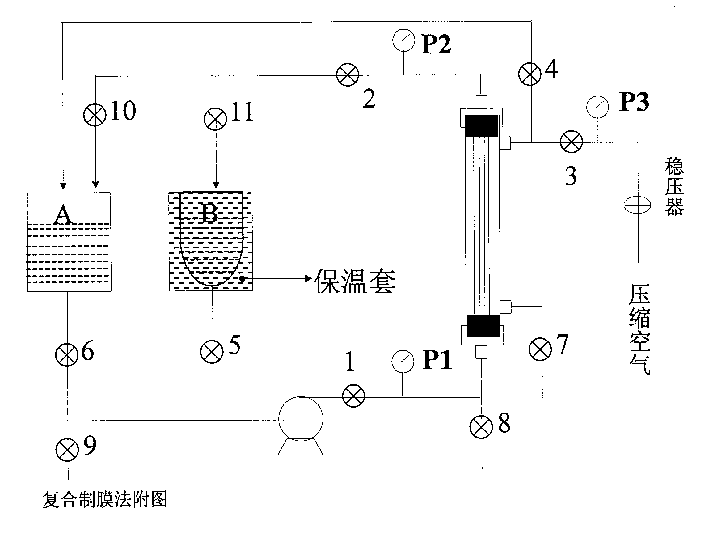

Method used

Image

Examples

Embodiment 4-10

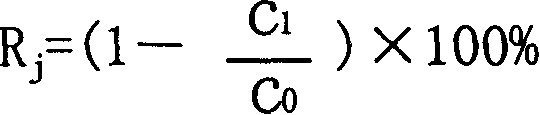

[0031] i. Example 4-10 composite process conditions: polyvinyl alcohol aqueous solution 2%, water bath 60 ° C, HCl 0.2%, 15min

[0032] serial number

[0033] From the data in Table 2, it can be seen that with the increase of the concentration of glutaraldehyde, the uniformity of the reaction film formation gradually increases, the compactness of the composite membrane also increases, and the PEG-4000 rejection rate of the hollow fiber membrane increases accordingly. The permeable flux also gradually decreased. When the concentration of glutaraldehyde is about 6%, the reaction film is basically uniform, and the water permeability of the membrane is also large. When the concentration of glutaraldehyde is too high, the thickness of the composite membrane is too large, so that the water permeability of the hollow fiber membrane The drop is larger.

[0034] ii. Example 11-17 Composite process conditions: glutaraldehyde aqueous solution 6%, water bath 60°C, HCl 0.2%, 15...

Embodiment 22-28

[0040] iv. Example 22-28 Composite process conditions: PVA aqueous solution 2%, glutaraldehyde aqueous solution 6%, water bath 60°C, HCl 0.2%

[0041] serial number

[0042]From the data in Table 5, it can be seen that with the increase of the reaction time, the uniformity of the reaction film formation gradually increases, the compactness of the composite membrane also increases, the PEG-4000 rejection rate of the hollow fiber membrane increases gradually, and the water permeability of the hollow fiber membrane increases. Flux also gradually decreased. When the reaction time is about 10 minutes, the reaction film formation is basically uniform, and the water permeation flux of the film is also relatively large.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap