High-throughput forward-osmosis membrane containing a-C3N4/Ag3PO4 composite material and preparation method thereof

A composite material and forward osmosis membrane technology, applied in the field of forward osmosis membranes, can solve problems such as membrane fouling and restricting the development of forward osmosis membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

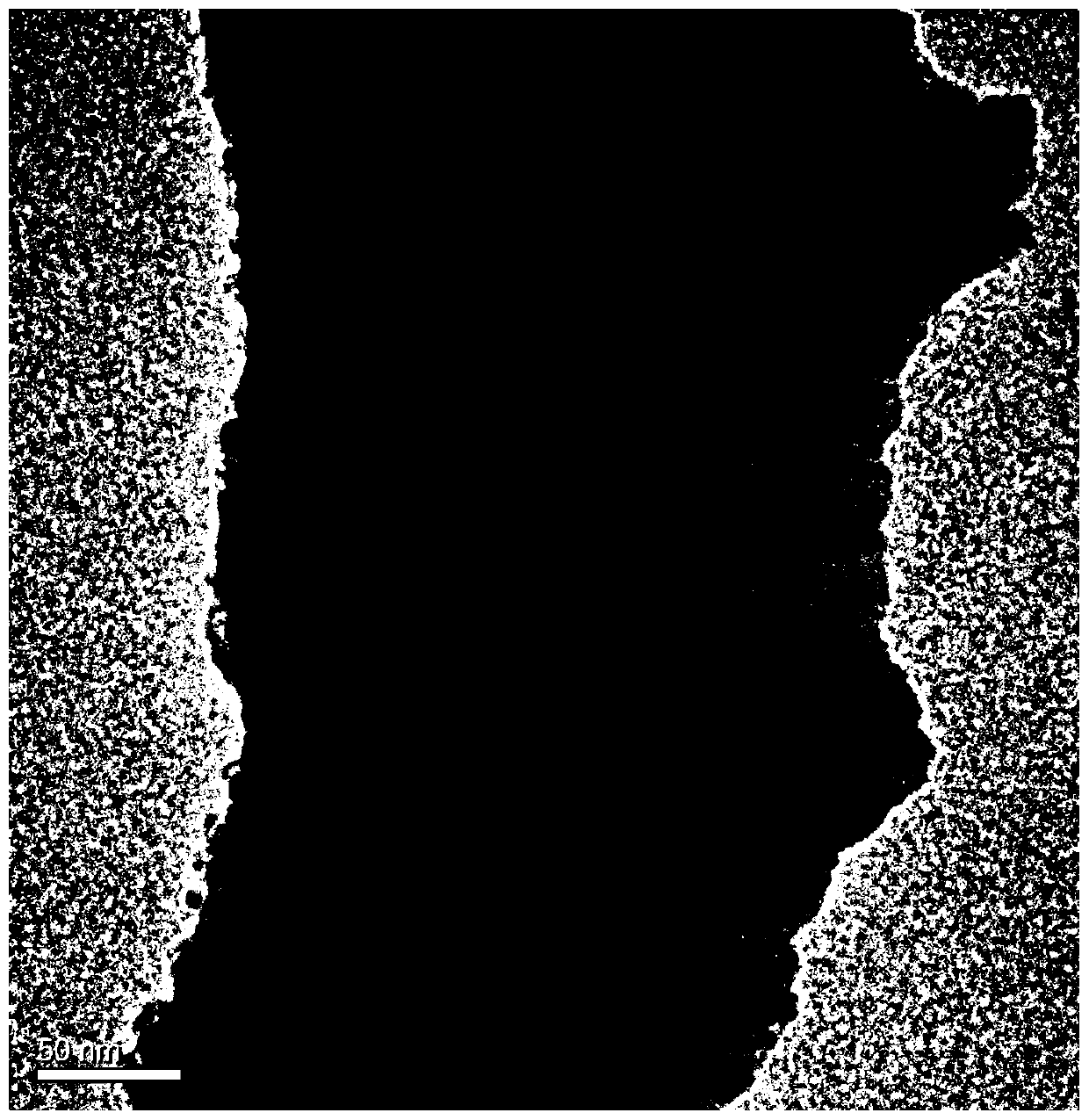

Image

Examples

Embodiment 1

[0056] A high-throughput a-C containing 3 N 4 / Ag 3 PO 4 The preparation method of forward osmosis membrane comprises steps as follows:

[0057] (1) Preparation of CNT dispersion: 10 mg of carbon nanotubes and 100 mg of sodium dodecylbenzenesulfonate were added to 100 ml of deionized water, and ultrasonically treated with a 300W power ultrasonic cleaner for 30 min to disperse the solute evenly in the solution. Then sonicate for 10 h with an ultrasonic cell pulverizer. Centrifuge the mixed solution for 30 minutes, take the supernatant and dilute 1 time with pure water to obtain a diluted solution; then add dopamine to the diluted solution under heating and stirring, add 10 mg of dopamine to every 150 mL of the diluted solution, keep stirring at 40°C for 1 hour, and add to the diluted solution. Add Tris-HCl buffer solution (pH=8.5) to the system, keep stirring at 40°C for 24 hours, add 10 mL of Tris-HCl buffer solution to every 150 mL of diluent, centrifuge the reacted dispe...

Embodiment 2

[0066] The high throughput containing a-C described in embodiment 1 3 N 4 / Ag 3 PO 4 The preparation method of the forward osmosis membrane, the difference is that,

[0067] In step (3), a-C in the aqueous phase solution 3 N 4 / Ag 3 PO 4 The concentration of composite material is 0.3g / L.

Embodiment 3

[0069] The high throughput containing a-C described in embodiment 1 3 N 4 / Ag 3 PO 4 The preparation method of the forward osmosis membrane, the difference is that,

[0070] In step (3), a-C in the aqueous phase solution 3 N 4 / Ag 3 PO 4 The concentration of composite material is 0.4g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com