Stereo electronic packaging structure containing conduction support base material

A technology of electronic packaging and conductive support, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, circuits, etc., and can solve the problems that heat energy is not easy to be removed, and it is not stackable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The aforesaid and other objects, features and advantages of the present invention will be made clearer through the following detailed description with reference to the illustrated preferred embodiments.

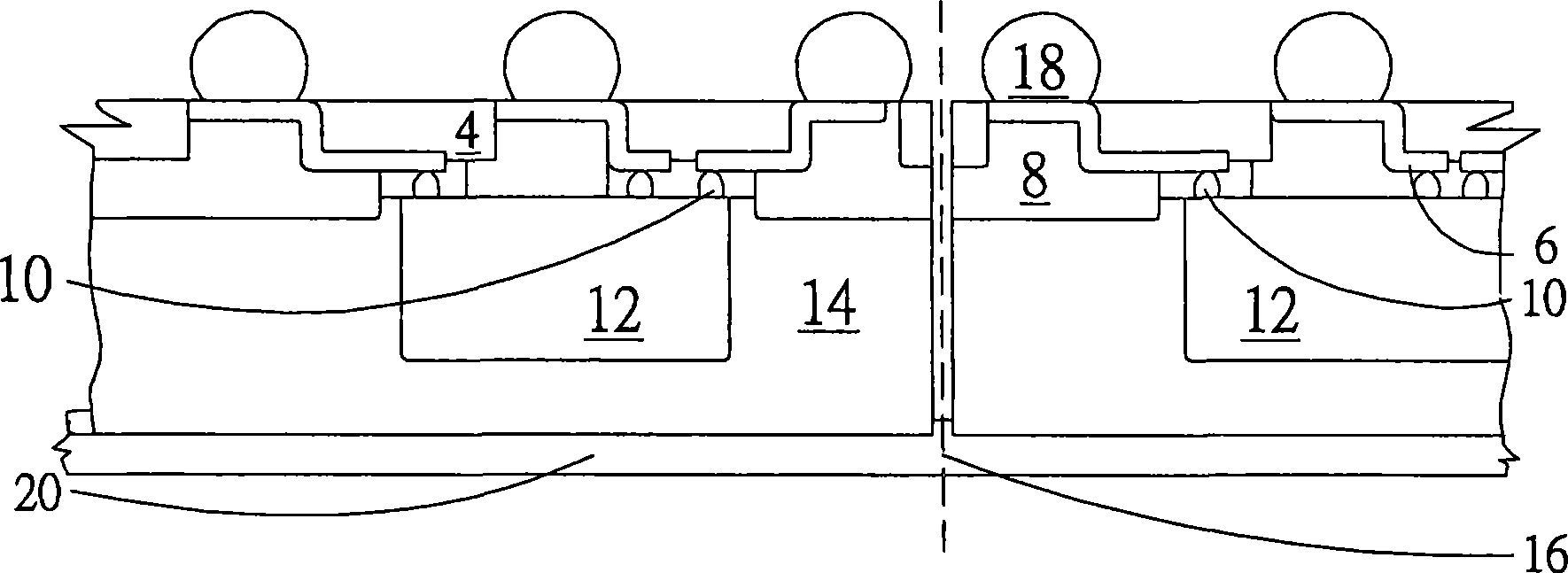

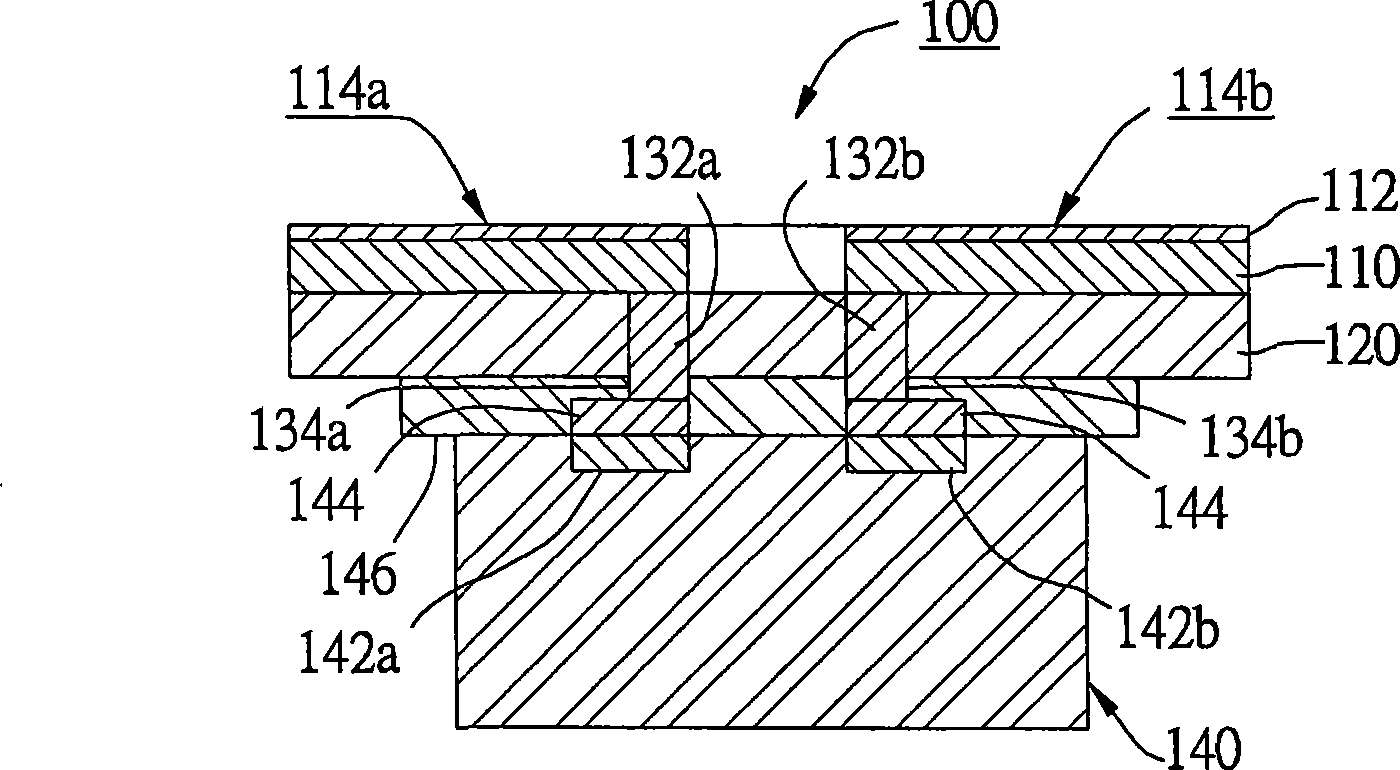

[0073] The invention discloses an electronic packaging structure. More specifically, the present invention provides a packaging unit with a conductive support base plate. The packaging unit can achieve the purpose of multi-chip stacking through the telecommunication contacts on both sides. The embodiments of the invention are described in detail as follows, but the preferred embodiments described are only for illustration and are not intended to limit the invention.

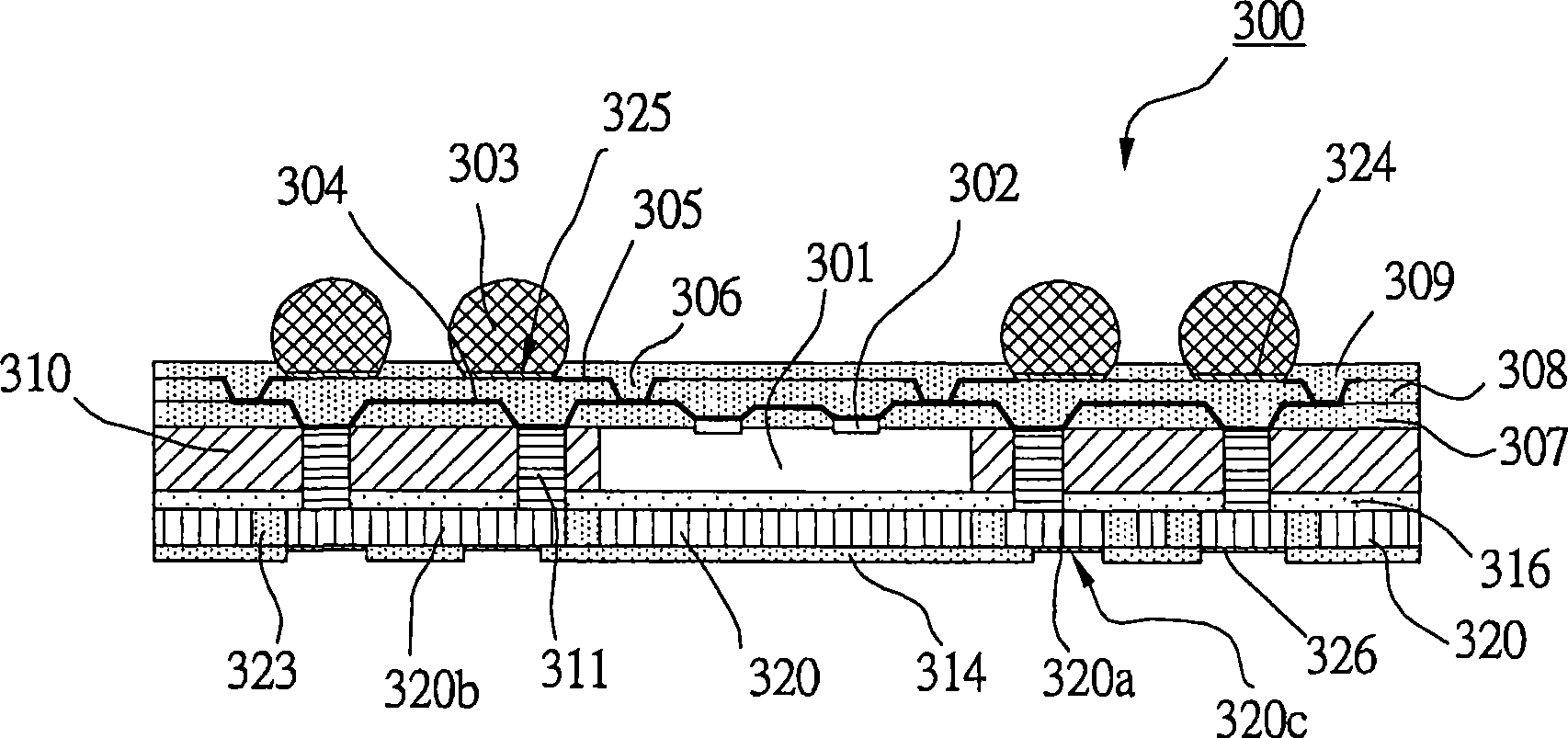

[0074] Figure 3a It is a cross-sectional view of the packaging unit of the present invention. The first packaging unit body 300 uses a supporting base plate 320 as a structural skeleton. The supporting base plate 320 with conductive properties can be copper, nickel, iron, aluminum, cobalt, gold or the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com