Studying-type detecting and fixing system and method

A maintenance system and learning technology, applied in error detection/correction, instruments, electrical and digital data processing, etc., can solve problems such as reducing customer satisfaction, detecting and repairing quality differences, and increasing inspection and maintenance manpower and material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

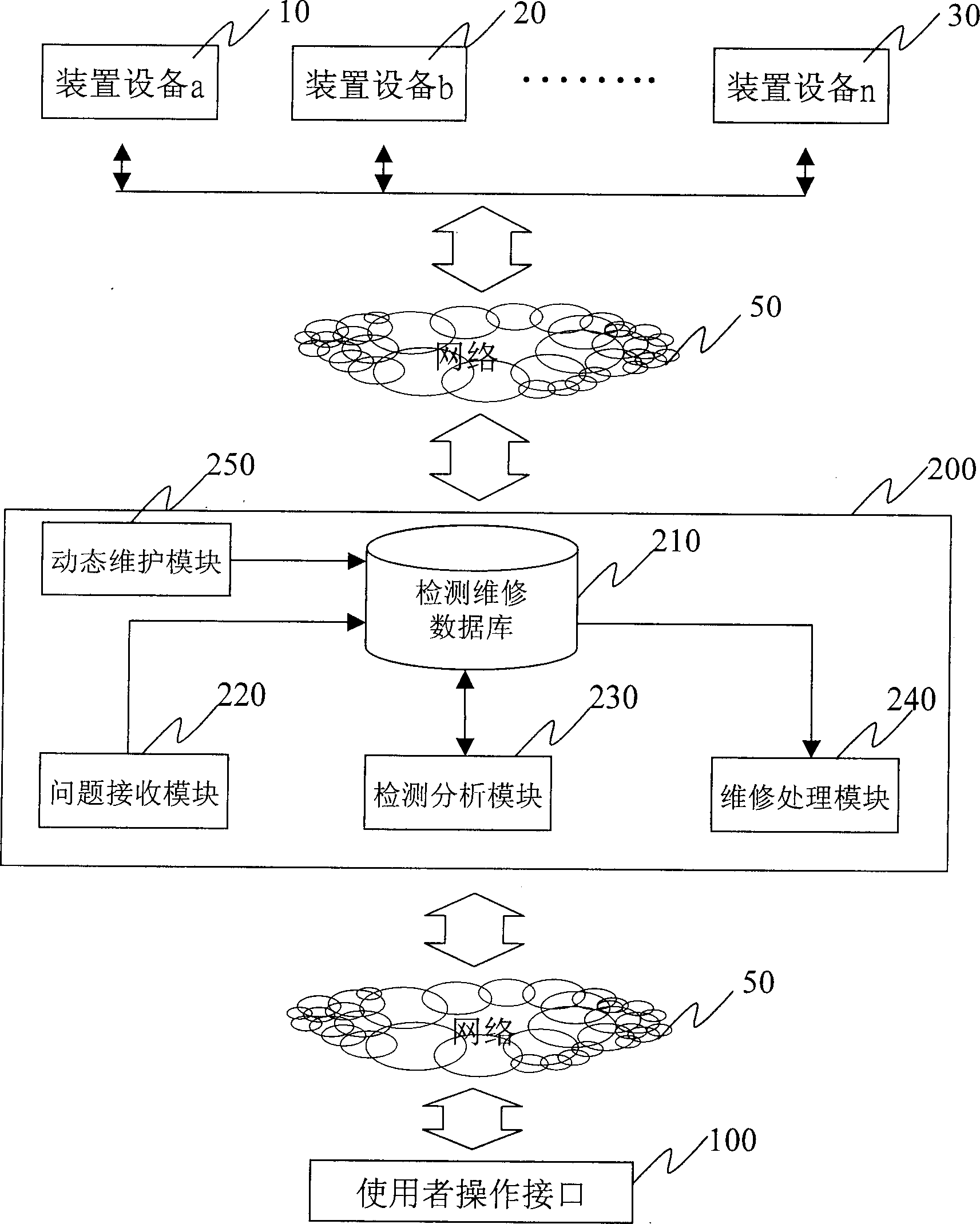

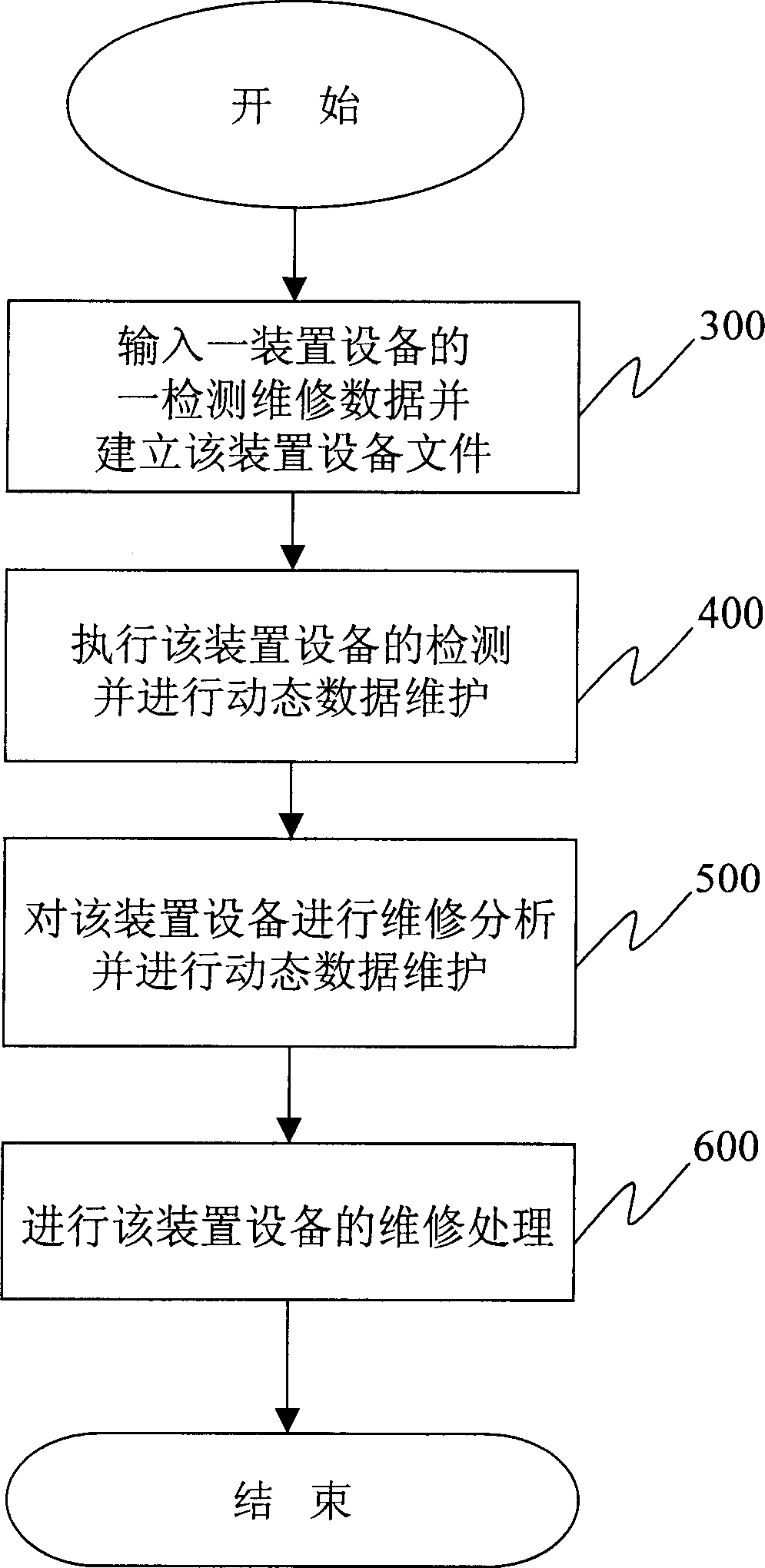

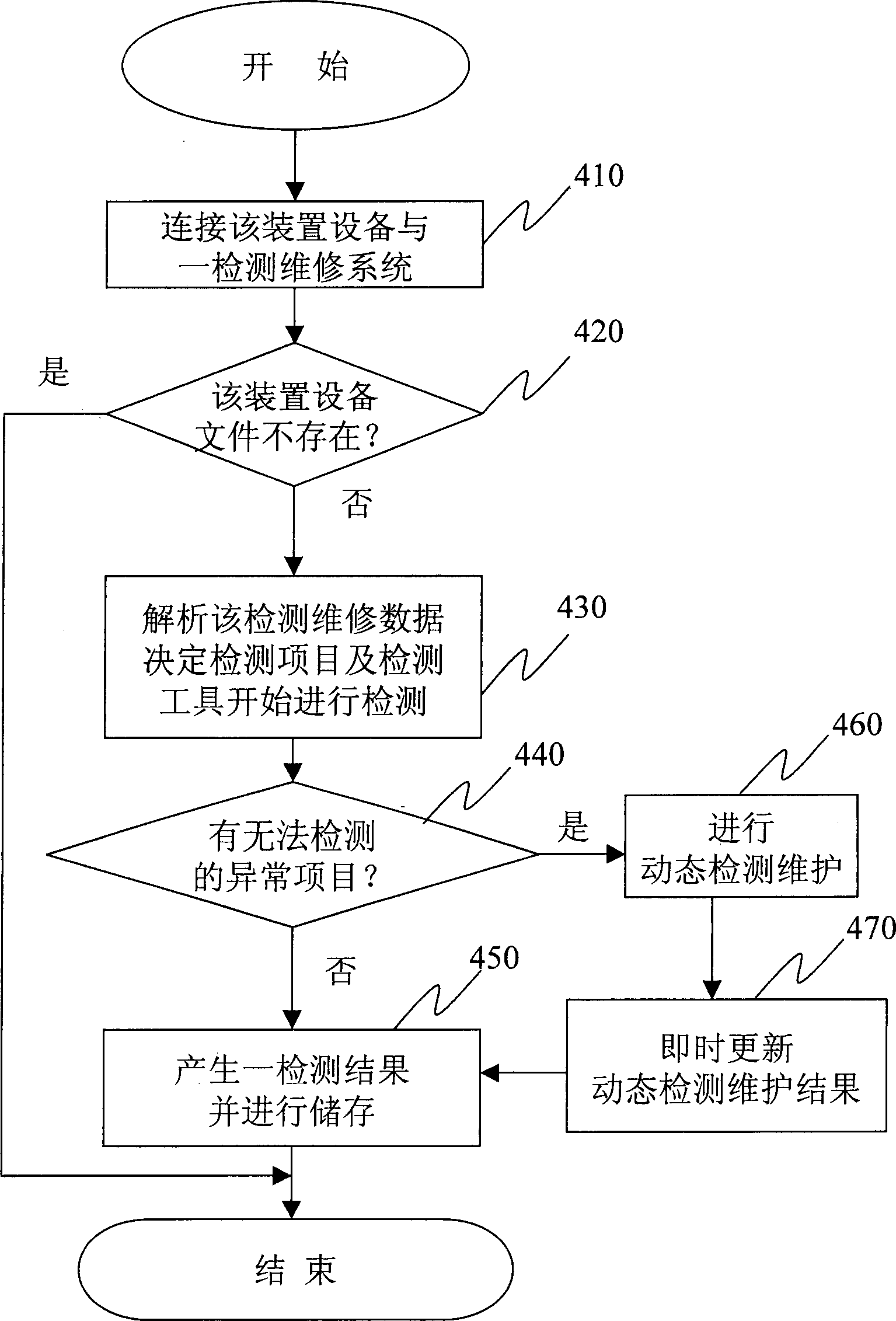

[0075] The present invention is a learning type detection and maintenance system and its method, please refer to figure 1 , which is a system operation framework diagram of the learning-type inspection and maintenance system and its method proposed by the present invention, which are described as follows:

[0076] In terms of the framework of system operation, it can basically be divided into three parts: one is the user operation interface 100; the other is the inspection and maintenance system 200 itself; part of the device n30...). The three are operated through the connection of the network 50. The customer can use the user operation interface 100 in a wired or wireless manner through the network 50 to input the inspection and maintenance data of the product to be inspected and repaired into the system and create a file in advance. Afterwards, when the inspection and maintenance personnel receive the device to be inspected and maintained, they only need to connect the dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com