Gear shifting operator for speed variator

A technology for shifting actuators and transmissions, which is applied to components with teeth, belts/chains/gears, mechanical equipment, etc., and can solve the problem of increased overshoot, increased device weight, and reliability may not be satisfied, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

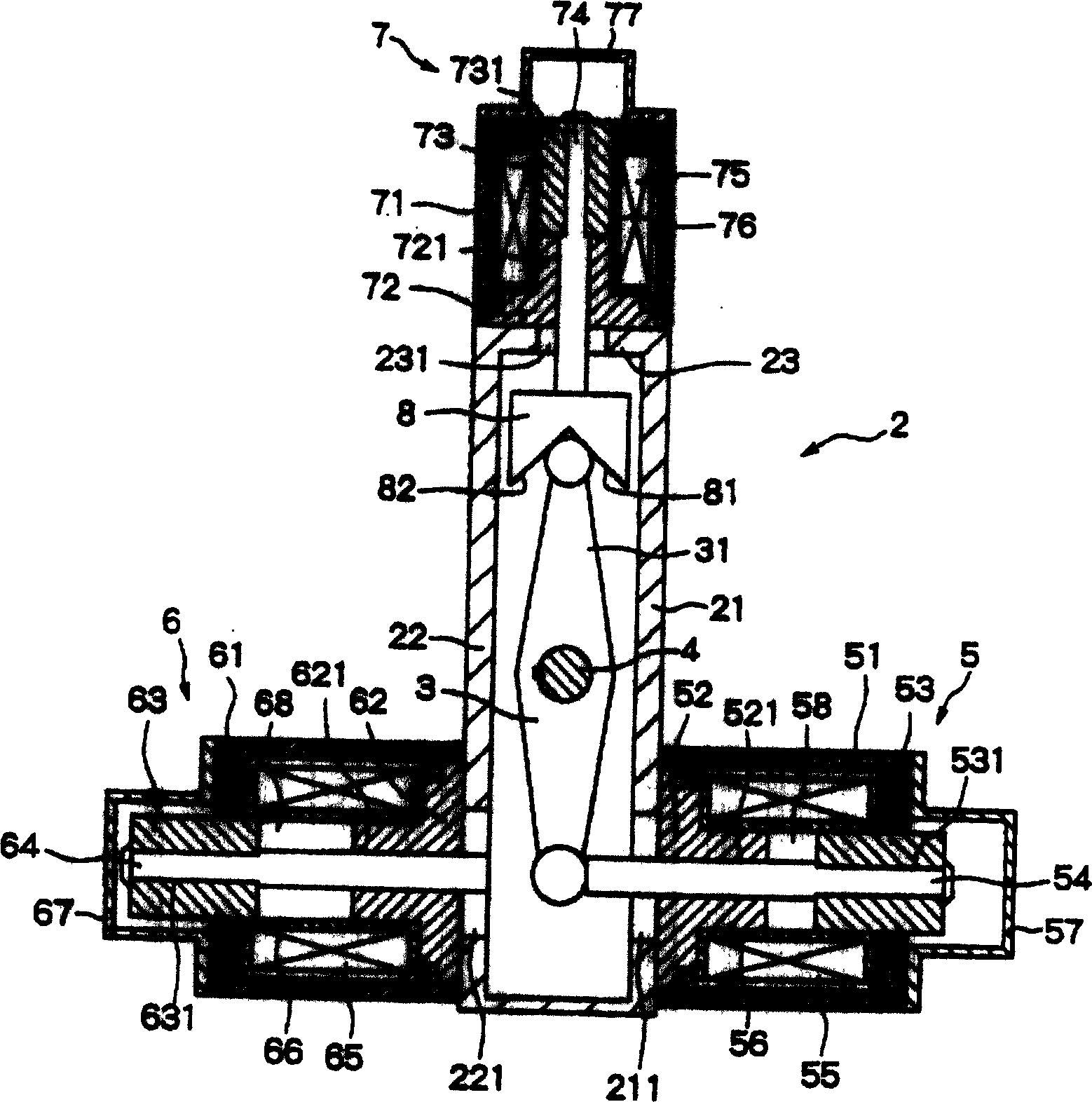

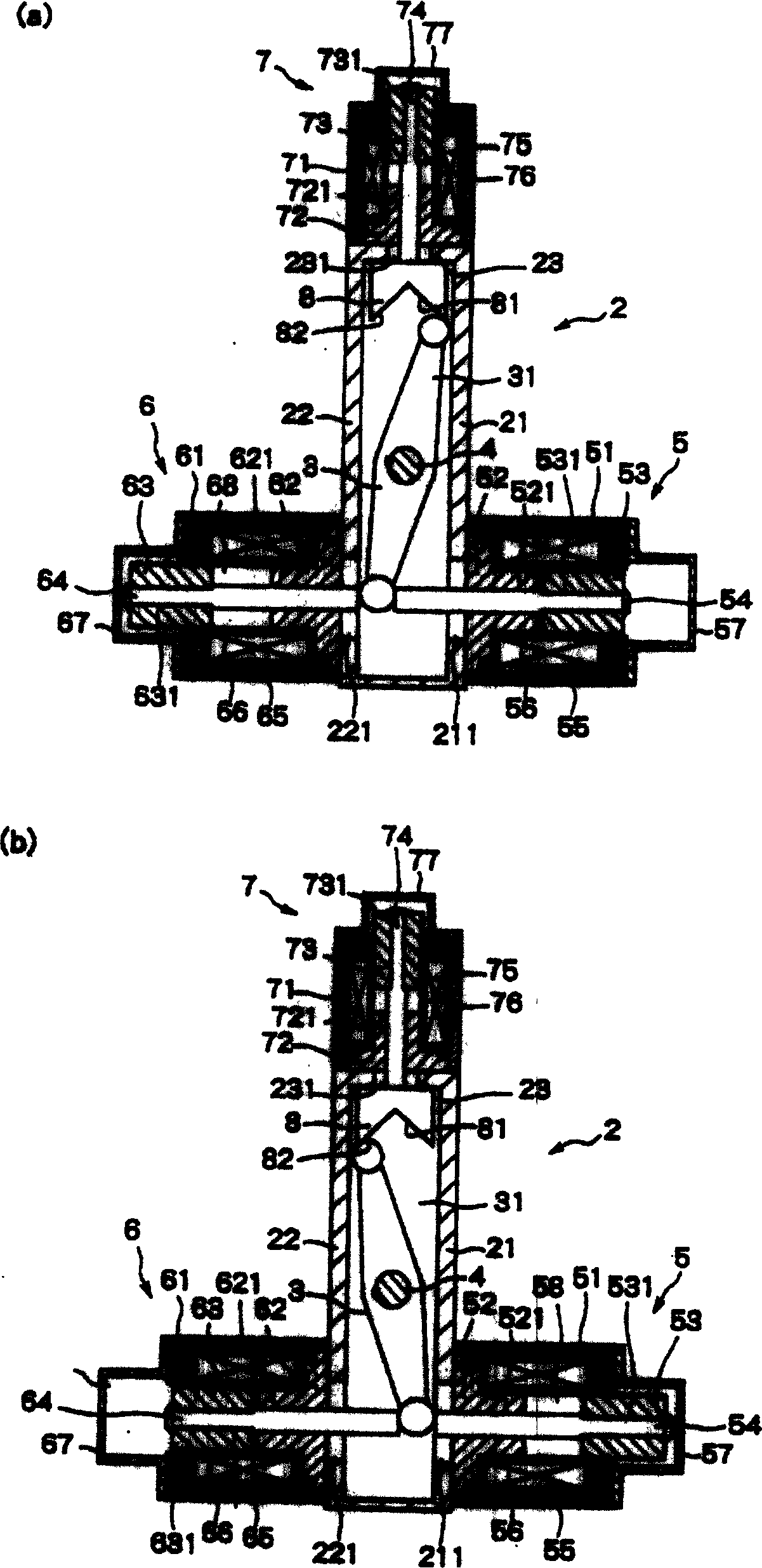

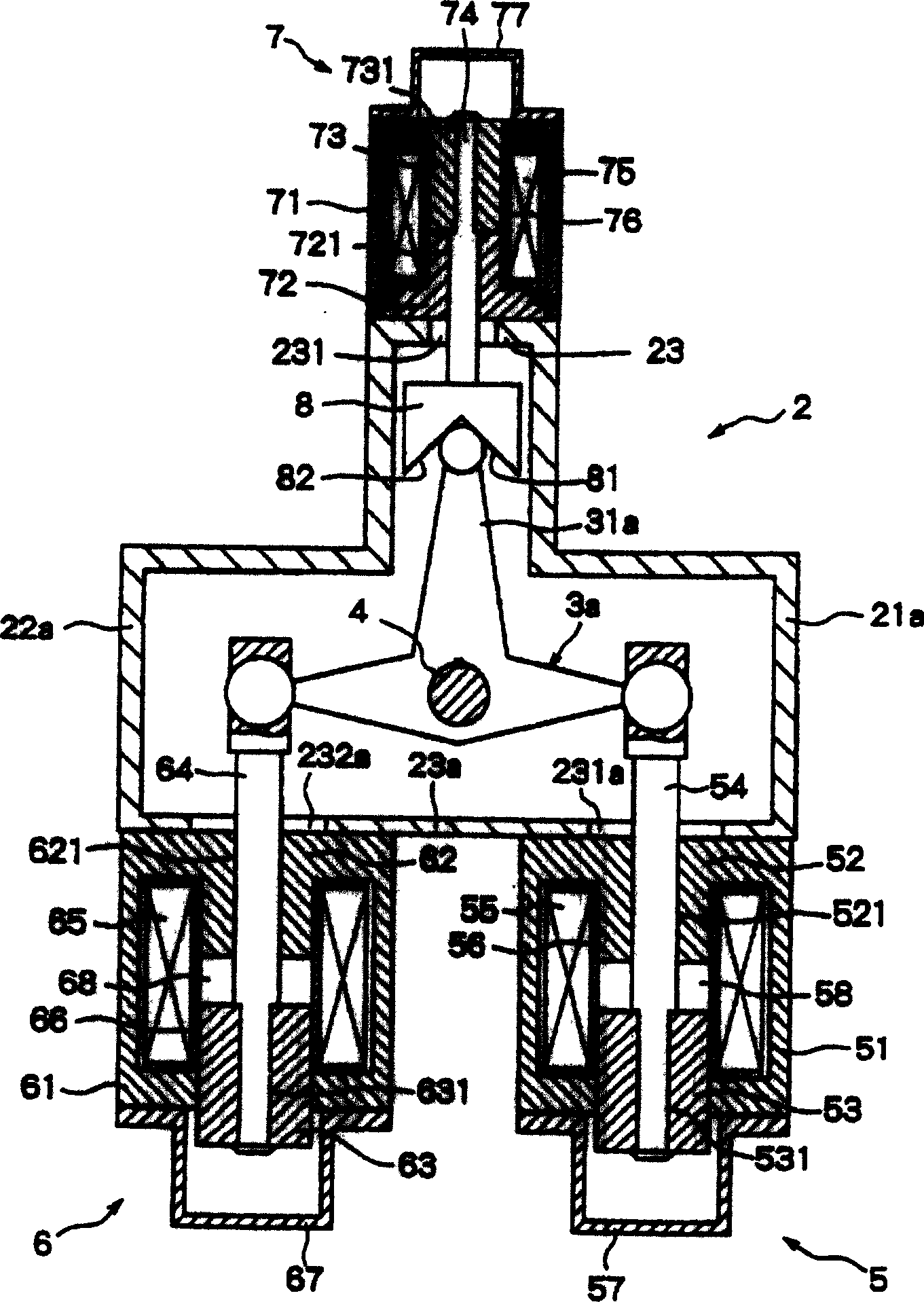

[0032] Hereinafter, embodiments of the shift actuator of the transmission according to the present invention will be described in detail with reference to the accompanying drawings.

[0033] figure 1 The first embodiment of the shift actuator of the transmission configured according to the present invention is shown. figure 1 The shift actuator shown has a housing 2 . Inside the housing 2, an actuating lever 3 that operates a shift shaft 4 constituting a shift mechanism of the transmission is arranged. The middle portion of the actuating lever 3 is attached to the shift shaft 4 . The first electromagnetic solenoid 5 and the second electromagnetic solenoid 6 are attached to the lower portions of the both side walls 21 and 22 of the casing 2, respectively. The first electromagnetic solenoid 5 actuates the actuating lever 3, that is, the shifting mechanism of the transmission to the first shifting position, and the second electromagnetic solenoid 6 actuates the actuating lever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com