Front shipping hook assembly for vehicle

A component and car body technology, applied to vehicle parts, motor vehicles, accessories for easy propulsion, etc., can solve problems such as damage to the front tow hook

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A preferred embodiment of the present invention will be specifically described below with reference to the accompanying drawings.

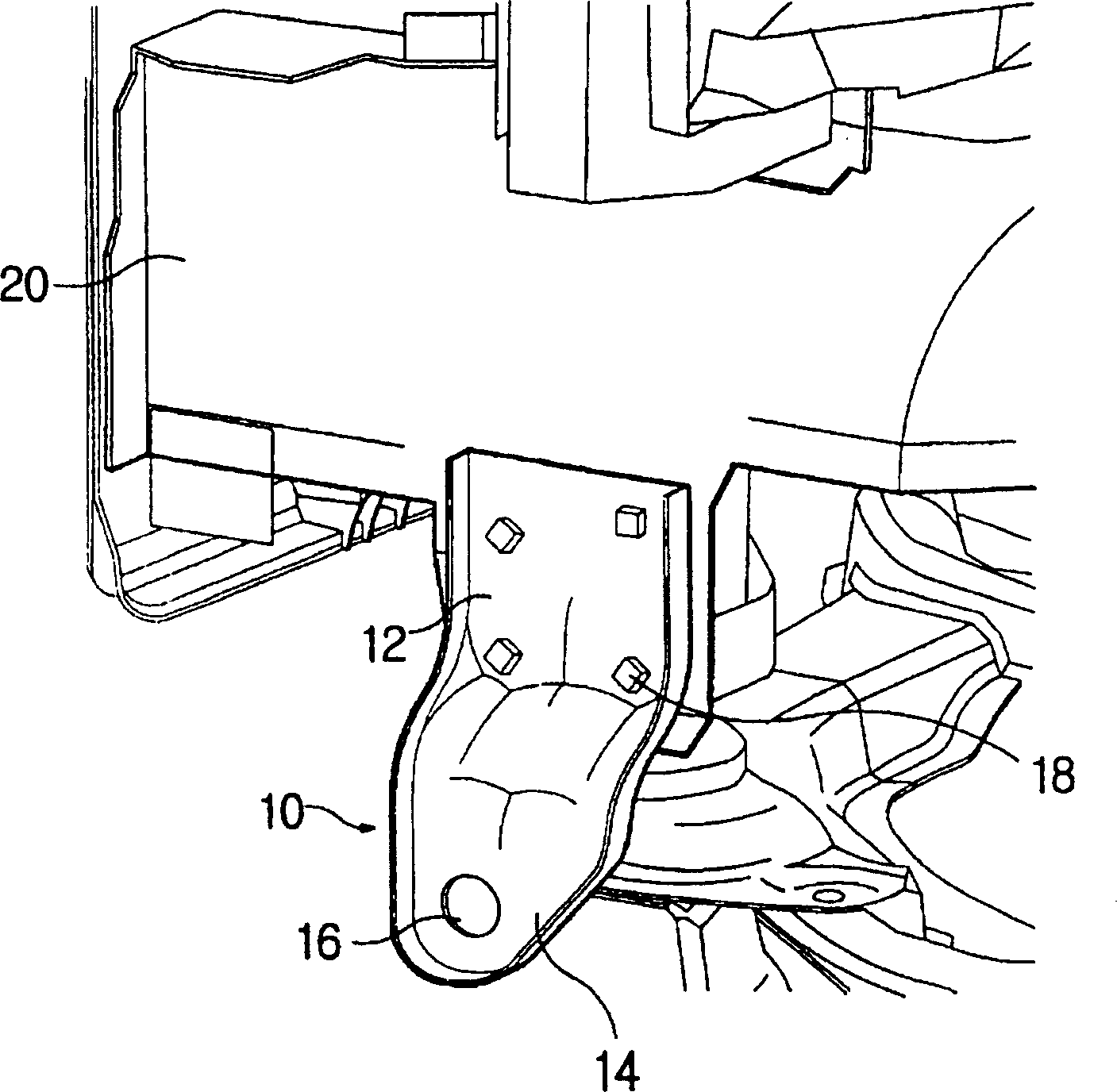

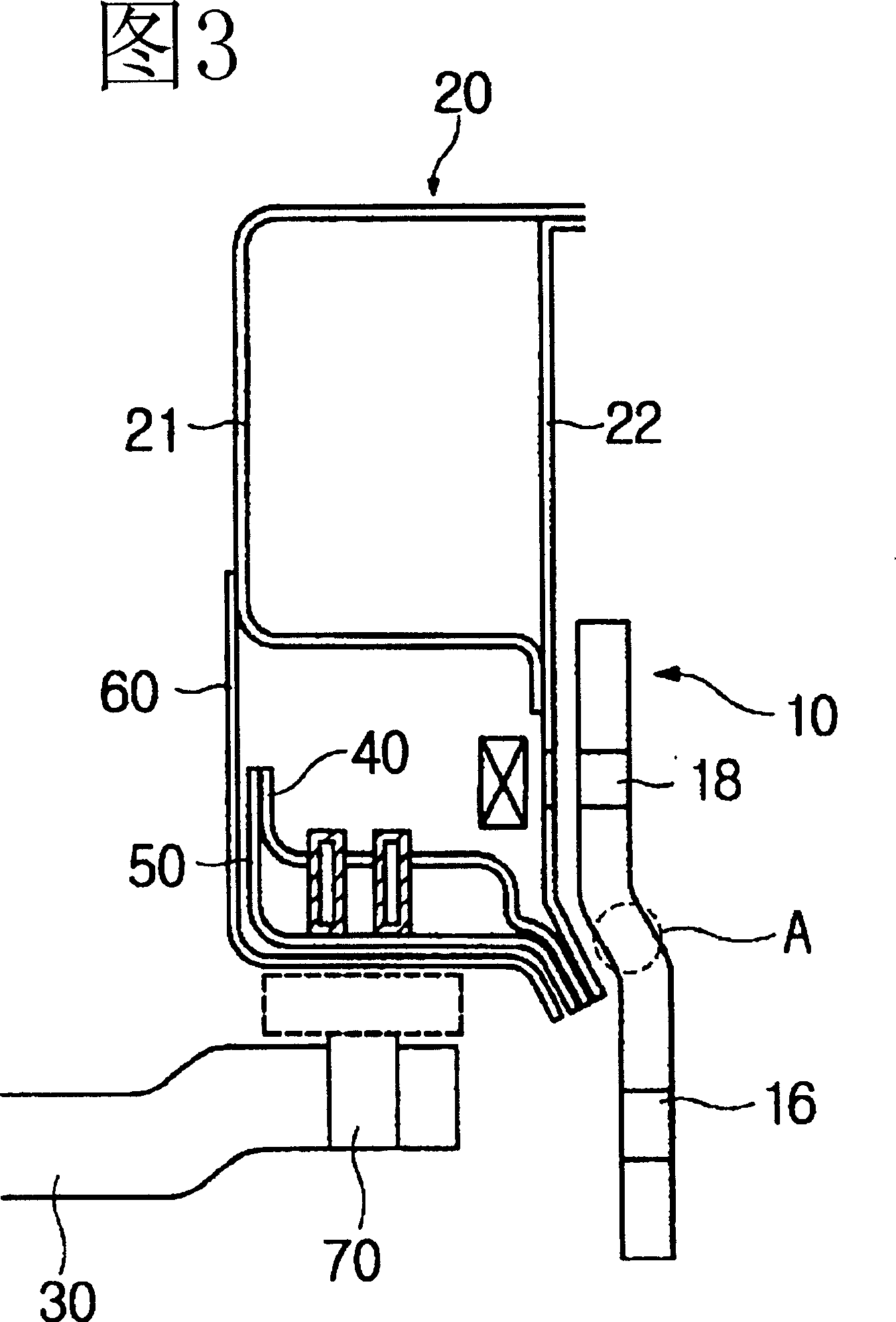

[0028] As shown in FIG. 4 , a front tow hook assembly 100 according to an embodiment of the present invention includes a front tow hook 110 and an installation unit 120 .

[0029] Such as Figure 5 As shown, the front tow hook 110 includes a connecting portion 111 , a vertical support 112 and a horizontal support 113 . The connection portion 111 is plate-shaped, and the connection portion 111 is at a position perpendicular to the lateral direction of the vehicle (Y direction in FIG. 4 ).

[0030] A hook hole 114 is formed on the connecting portion 111, and the hook hole 114 is configured to be hooked by a hook-shaped device for towing or tying the vehicle.

[0031] The vertical support 112 extends from the connection portion 111 in an oblique direction and then extends vertically. The vertical support 112 has a shape of a rectangular pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com