Electric drop bolt with slidable drive mechanism

A latch and joint technology, applied in the field of safety locks, can solve problems such as jamming and asynchronous driving mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

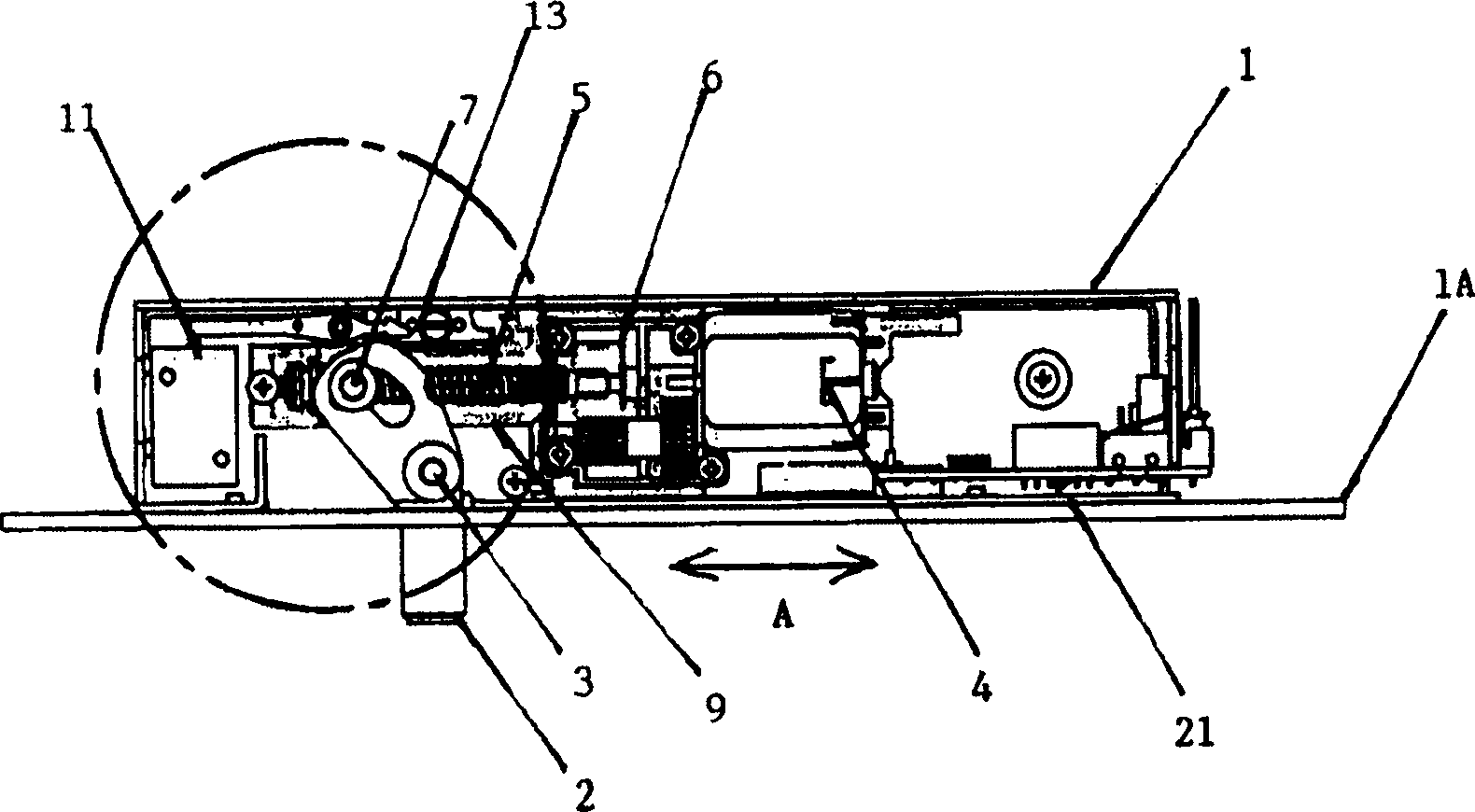

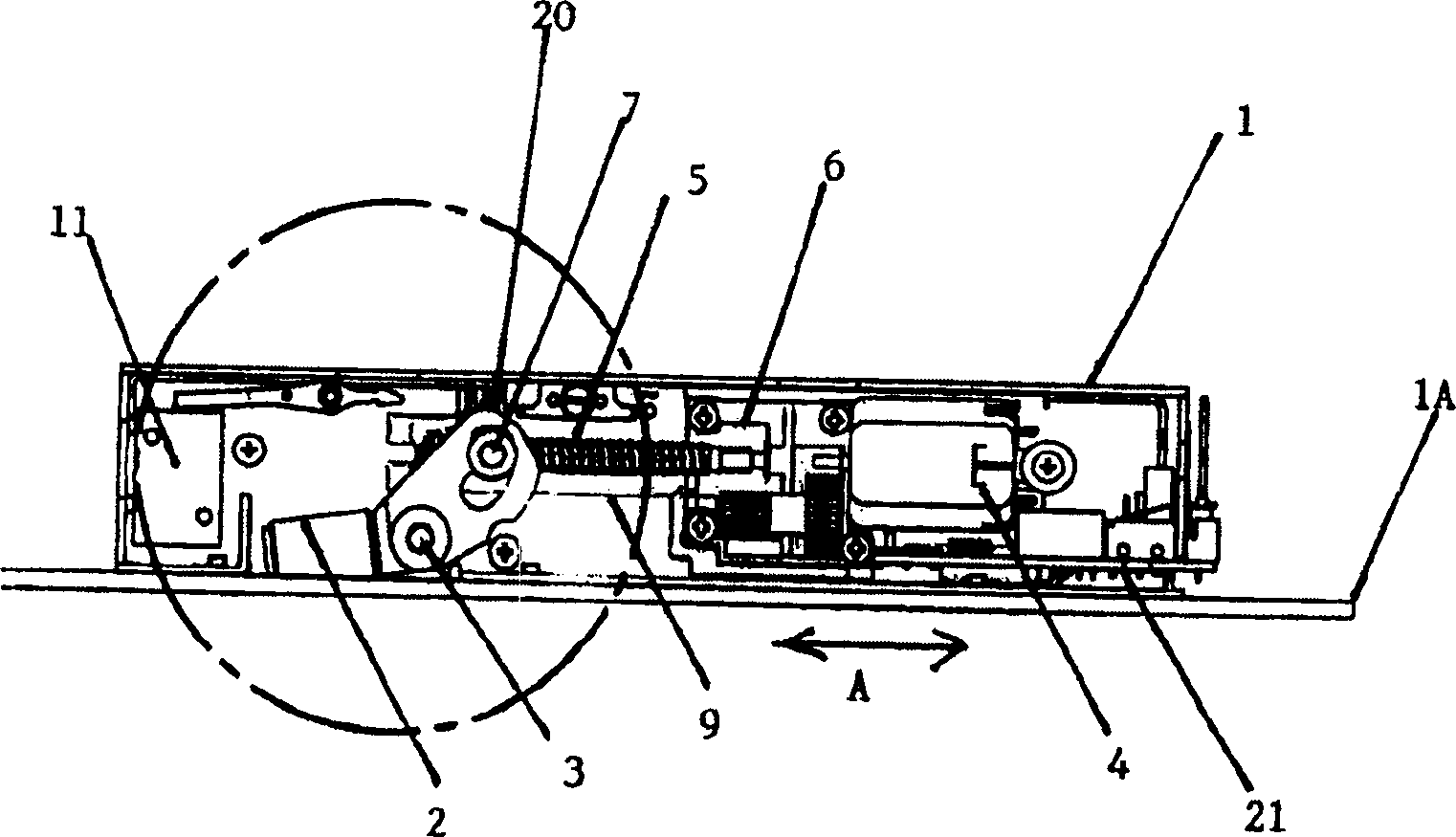

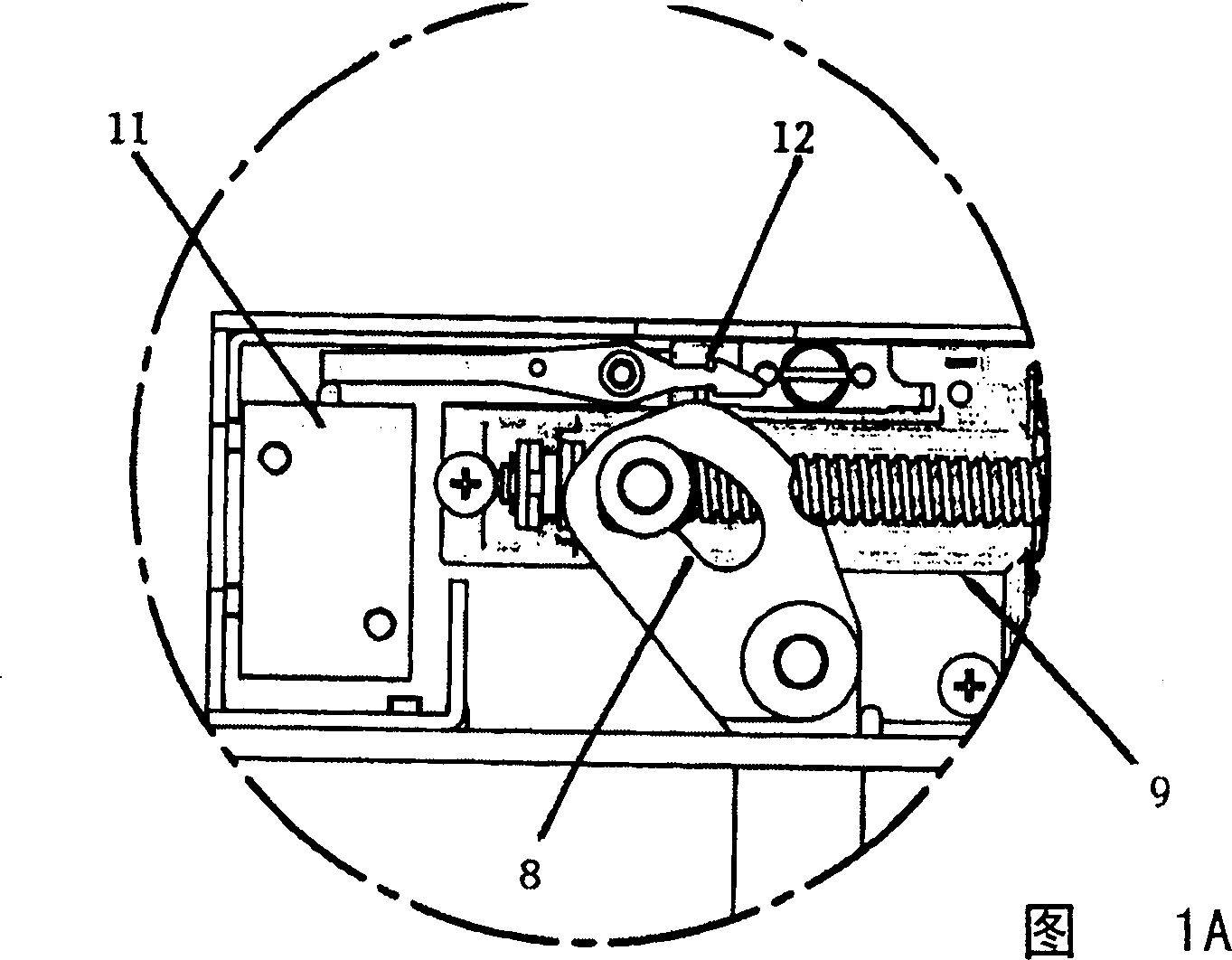

[0015] see first figure 1 , shows an electric lock comprising a casing 1 suitable for being installed in a door frame with an outward facing panel 1A. The housing has a latch 2 which is pivotable about a pin 3 so that it can be figure 1 Movement between a locked configuration shown in and an unlocked configuration in which the latch 2 protrudes out of the frame and in the unlocked configuration the latch 2 is substantially inside the housing. The mechanical drive assembly for the latch consists of an electric motor 4 rotating a screw shaft 5 via a reduction gear 6 . A roller nut 7 is mounted on the screw shaft 5, and when said shaft is turned by the motor, the roller nut 7 moves along the length of the shaft. The roller nut 7 in turn engages a closed cam surface 8 formed as part of the latch 2 . When the mechanical drive assembly is in figure 1 In the normal operating position shown in , the roller nut moves to figure 1 The left end or the right end (not shown) of the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com