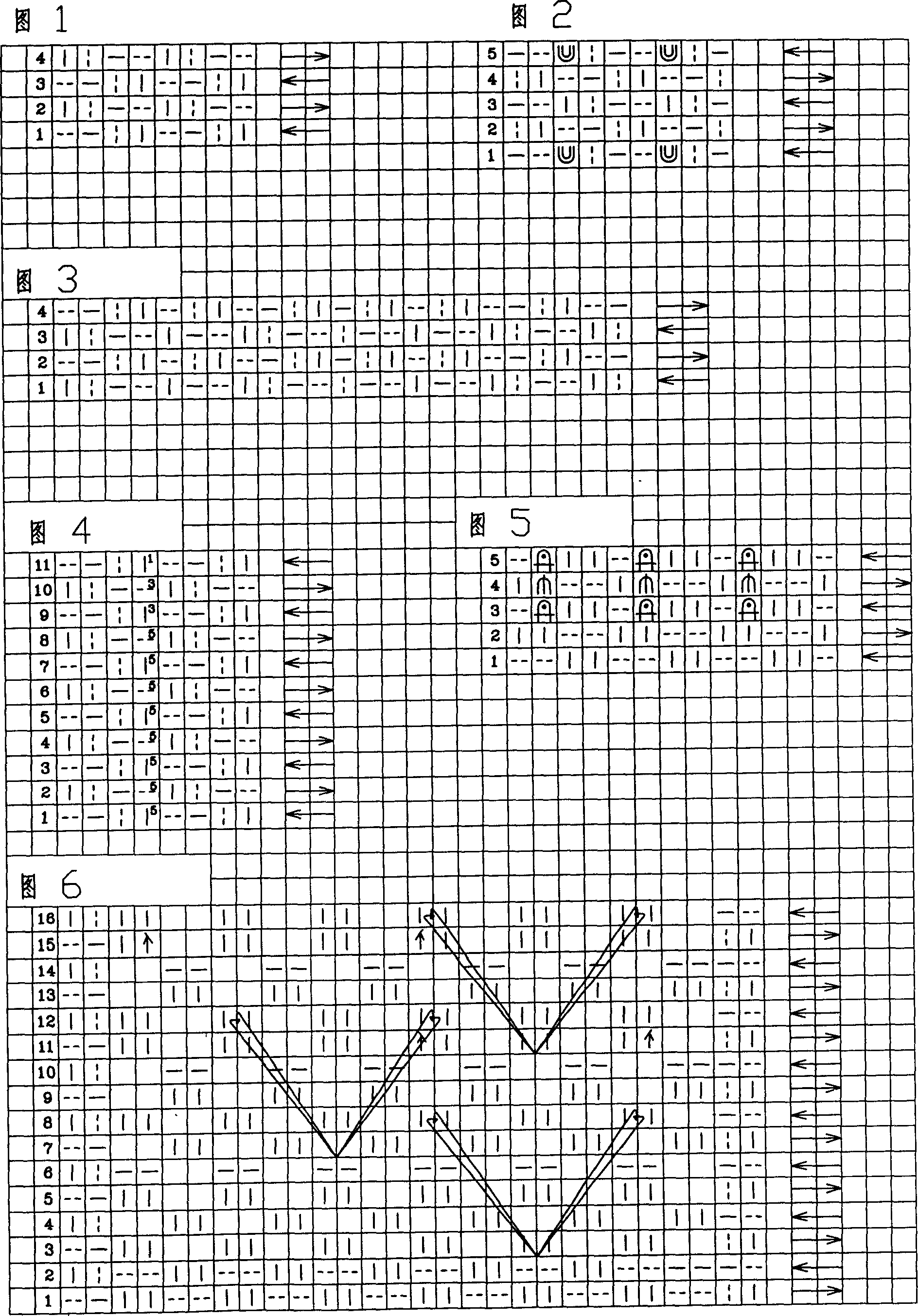

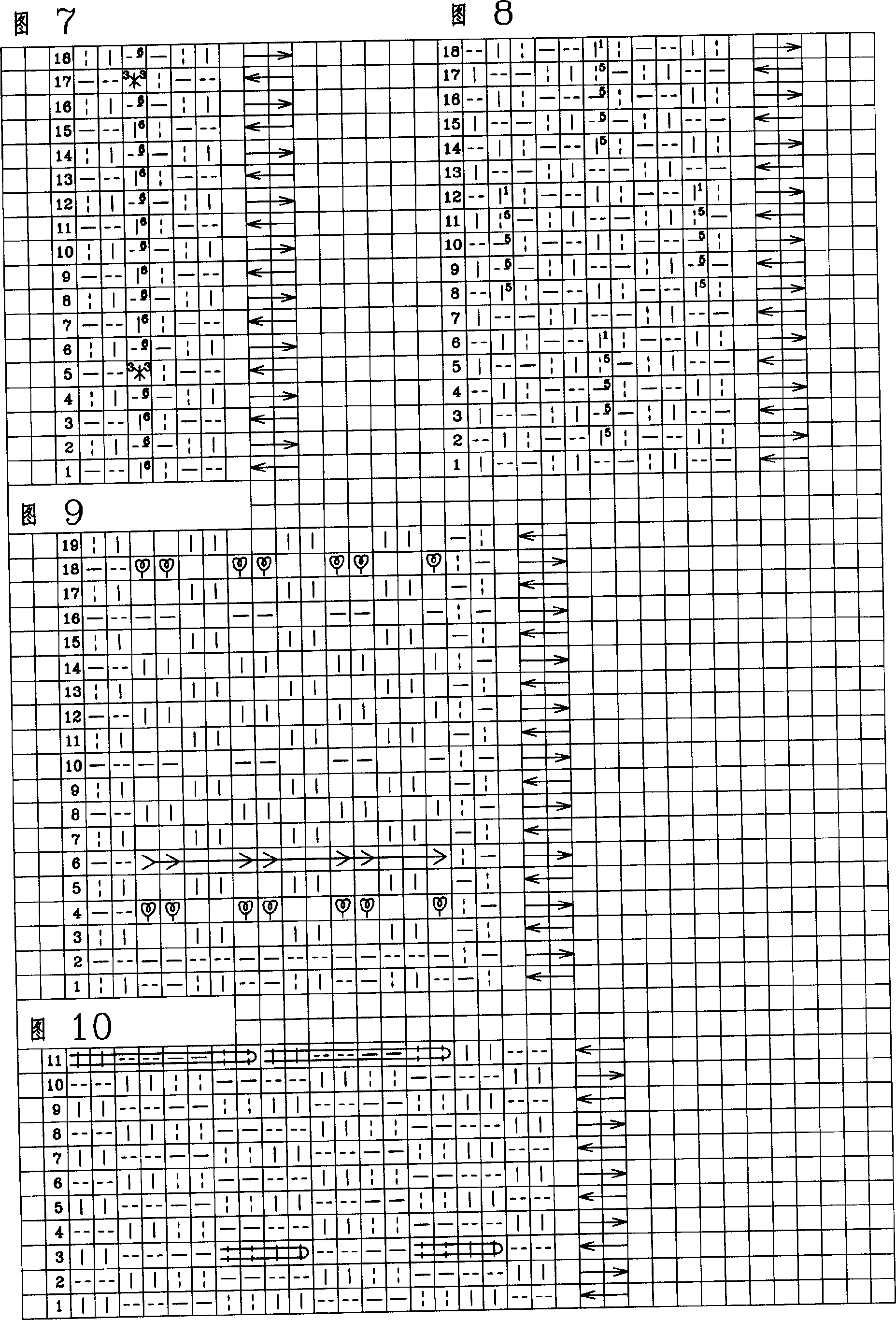

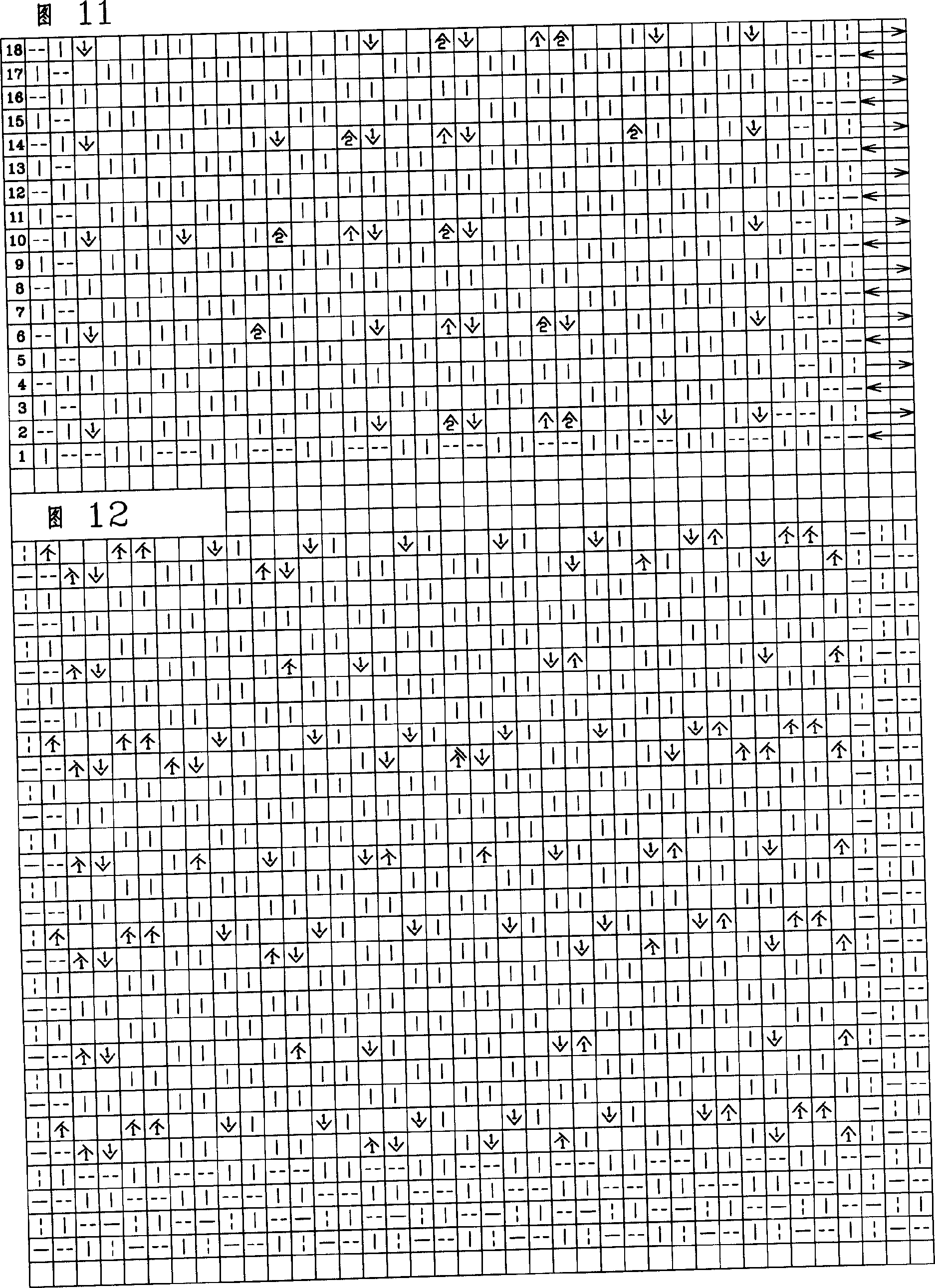

Method for braiding compound rib double-layer and double-side fabric by bar needles

A technology for weaving composite and knitted fabrics, which is applied in the direction of knitted fabrics, hand-woven fabrics, textiles and papermaking, etc., and can solve problems such as stiff hand feeling, inappropriate wearing, and inability to weave.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0659] Under normal circumstances, for weavers, whether weaving sheet fabrics or cylindrical fabrics, weaving is done from right to left, and the present invention is the same, and no matter single-color or double-color double-colored fabrics described in the present invention For double-sided fabrics, use the same number of needles as usual, 2 needles for sheet fabrics and 4 needles for cylindrical fabrics.

[0660] Because the present invention is simple in equipment (all production main tools are stick needles and crochet needles), it does not need a fixed and huge factory building, as long as there is a fixed warehouse, thus the production cost is low. Because it is knitted with stick needles, it can be produced at home after training, which not only takes care of the family, but also reduces traffic pressure and production costs. Generally, older laid-off female workers who can knit can do this work. The invention can produce wearing articles, decorative articles, bedding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com