An opening-force-maximizing device of an underpressure-activated valve for a drinking container

A technology for drinking containers and low-pressure starting, which is applied in packaging, transportation and packaging, thin material handling, etc., and can solve the problems of weakened functionality and user-friendliness, small effective membrane area, and impracticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

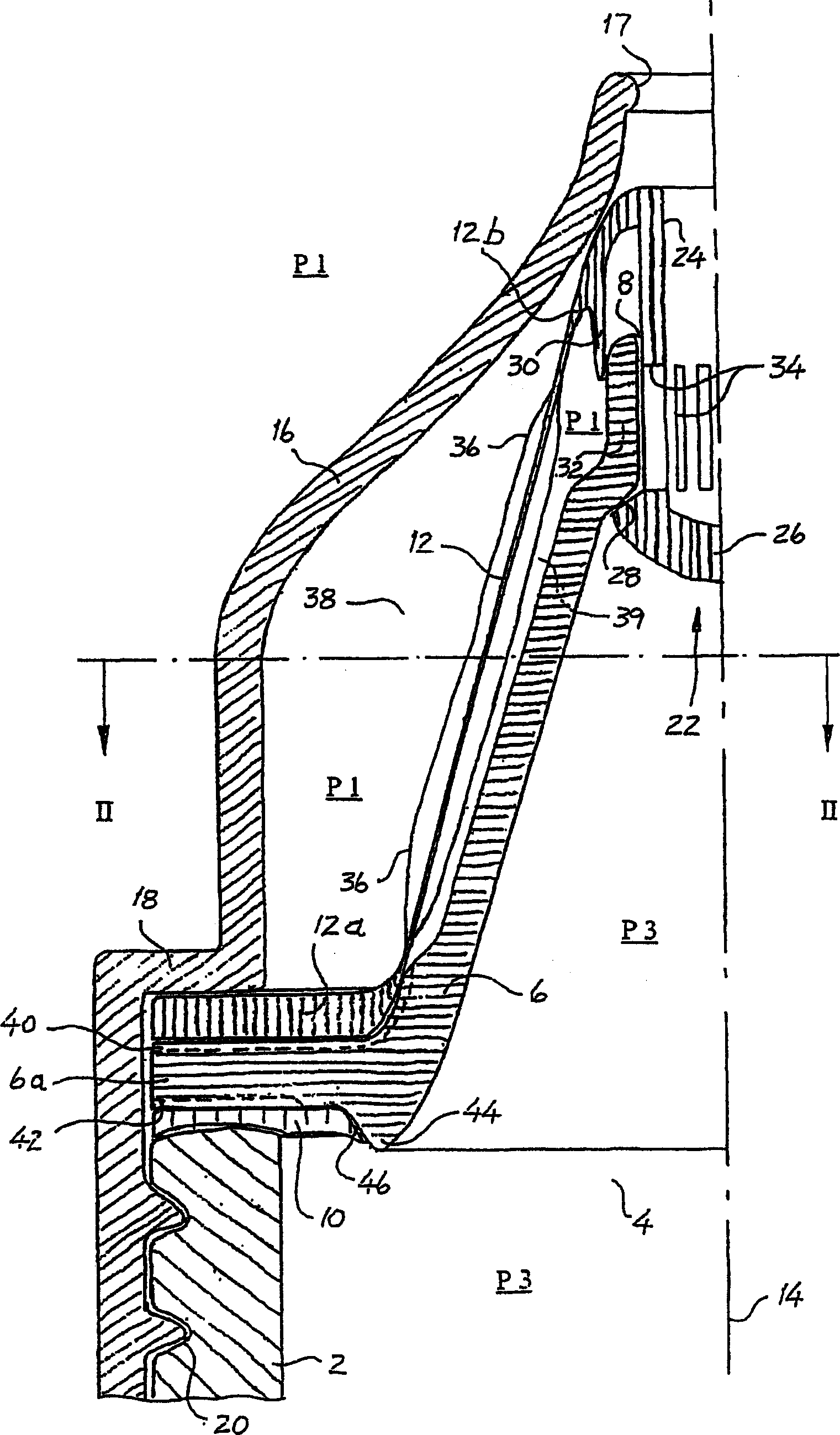

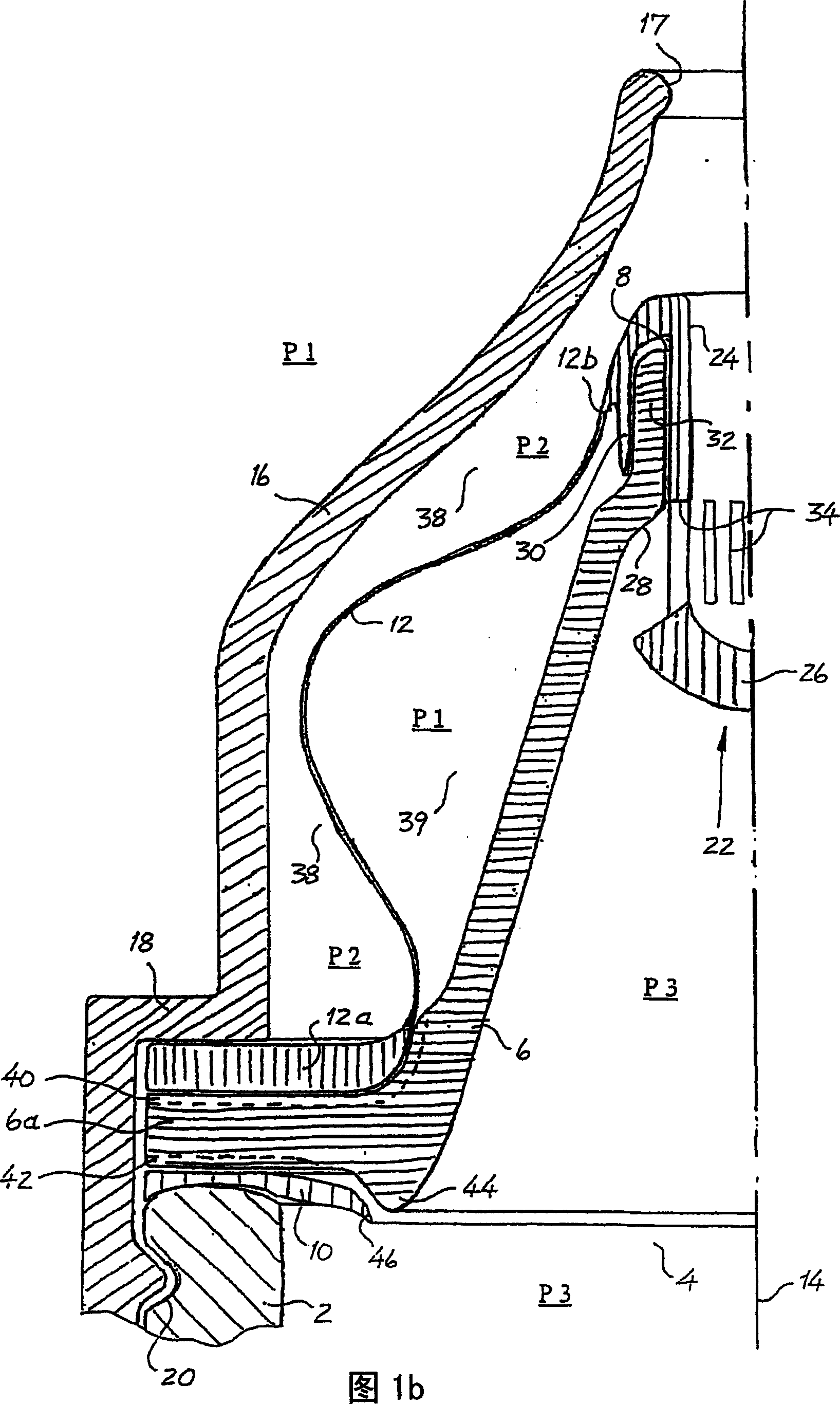

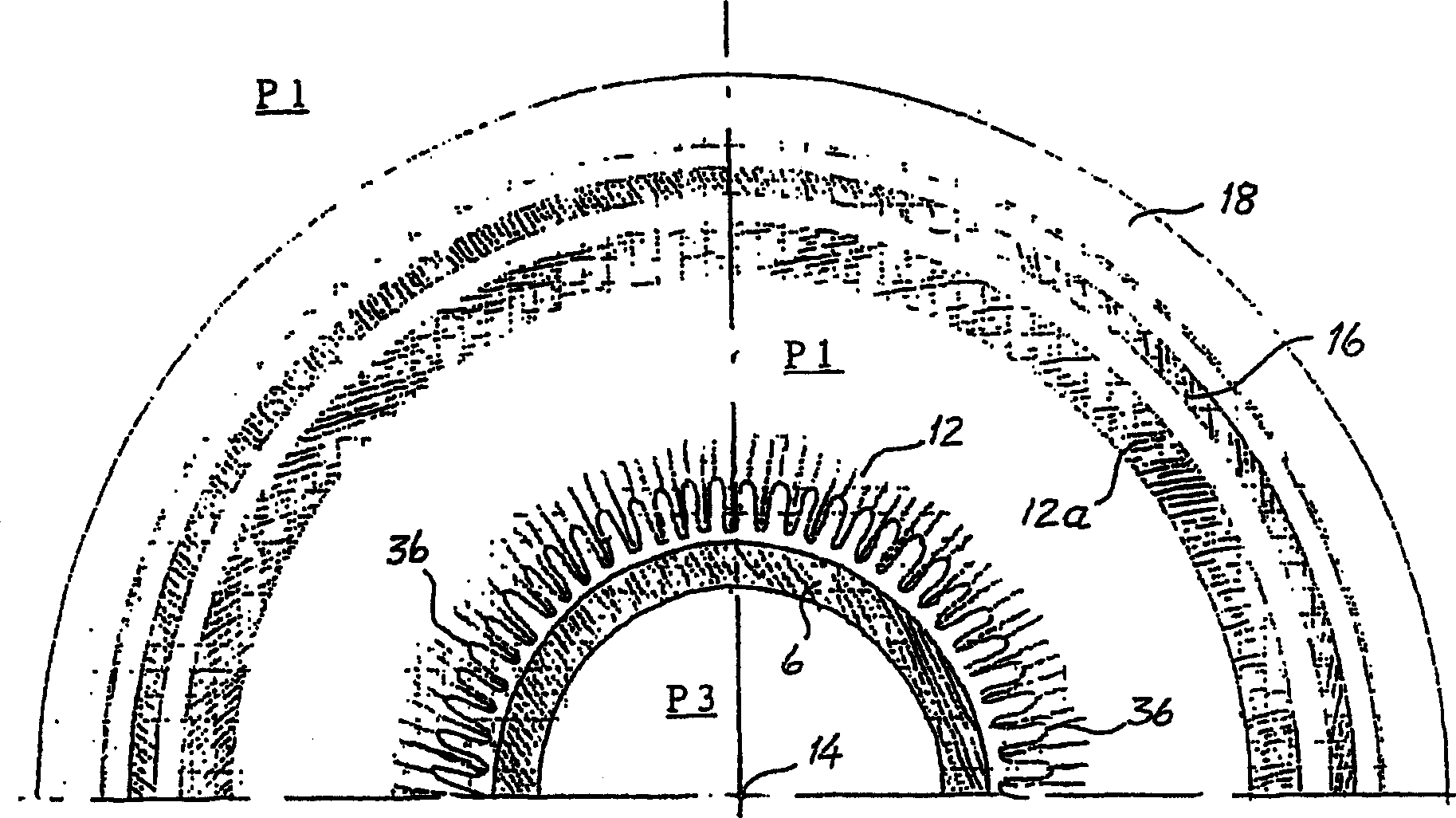

[0042] Figure 1a and FIG. 1 b shows a bottle 2 with a mouth 4 to which a maximum opening force valve arrangement according to the invention is attached. A pressure P3 exists inside the bottle 2, while the bottle is surrounded by an ambient pressure P1. Therein, the valve device comprises a conical partition wall 6 with a peripheral circumferential rim 6 a and a wall opening 8 , which is connected to the bottle 2 and surrounds the bottle mouth 4 in a pressure-tight manner via a gasket 10 .

[0043] The valve means also comprises a peripheral continuous conical membrane 12 . The membrane 12 is arranged on the outside of the bottle 2 and is concentric about a valve axis 14 passing through the valve opening 8 on the partition wall 6 . Furthermore, all valves in the described and subsequent exemplary embodiments are concentric about the valve axis 14 . Also, the membrane 12 has an axial length with respect to the valve shaft 14, whereby the membrane 12 has two axial terminations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com