Driving device capable of switching speed reduction ratio

A technology of transmission and reduction ratio, which is applied in the direction of transmission, transmission control, and components with teeth, etc., which can solve the problems of large space and unfavorable miniaturization of scanning devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

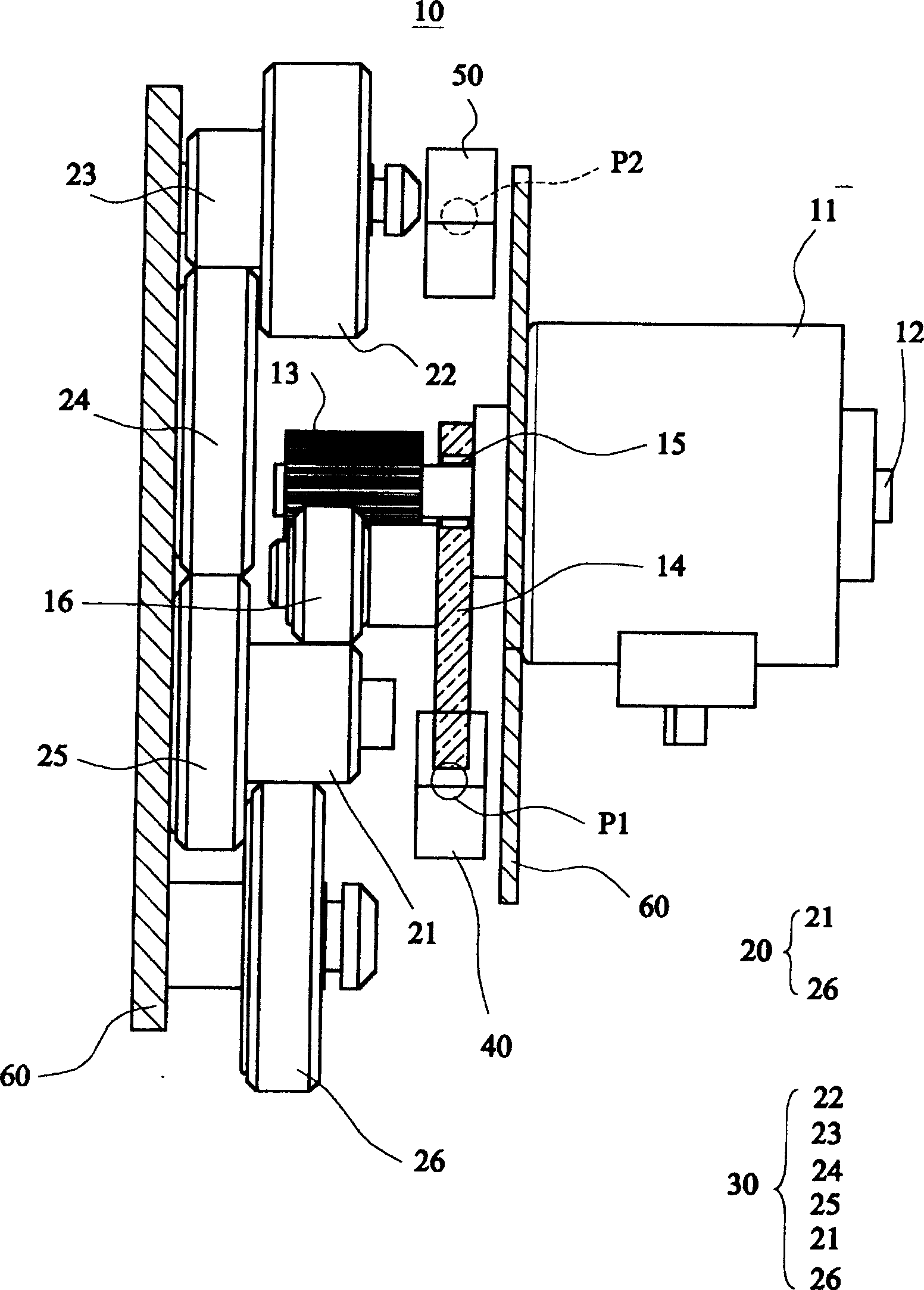

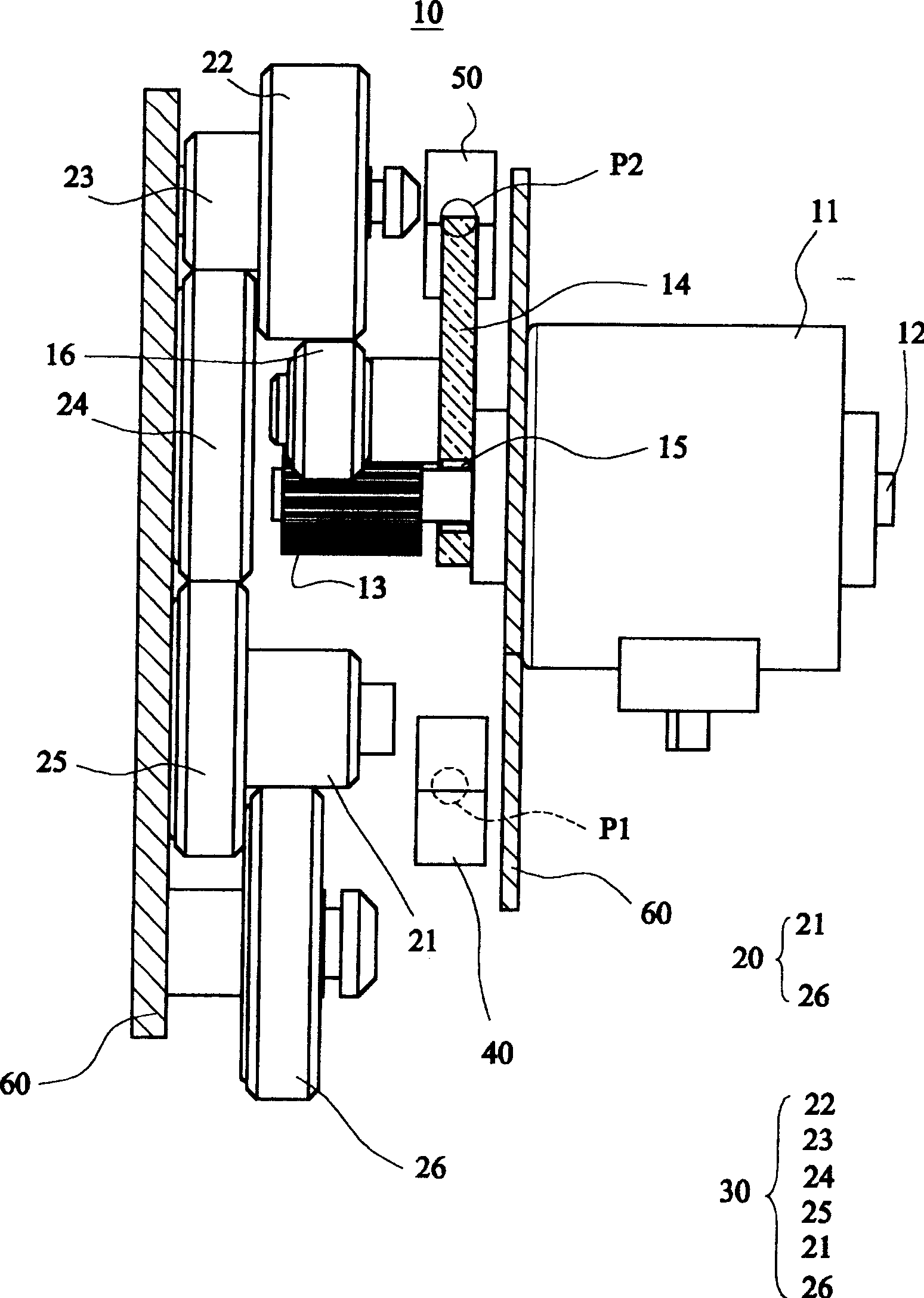

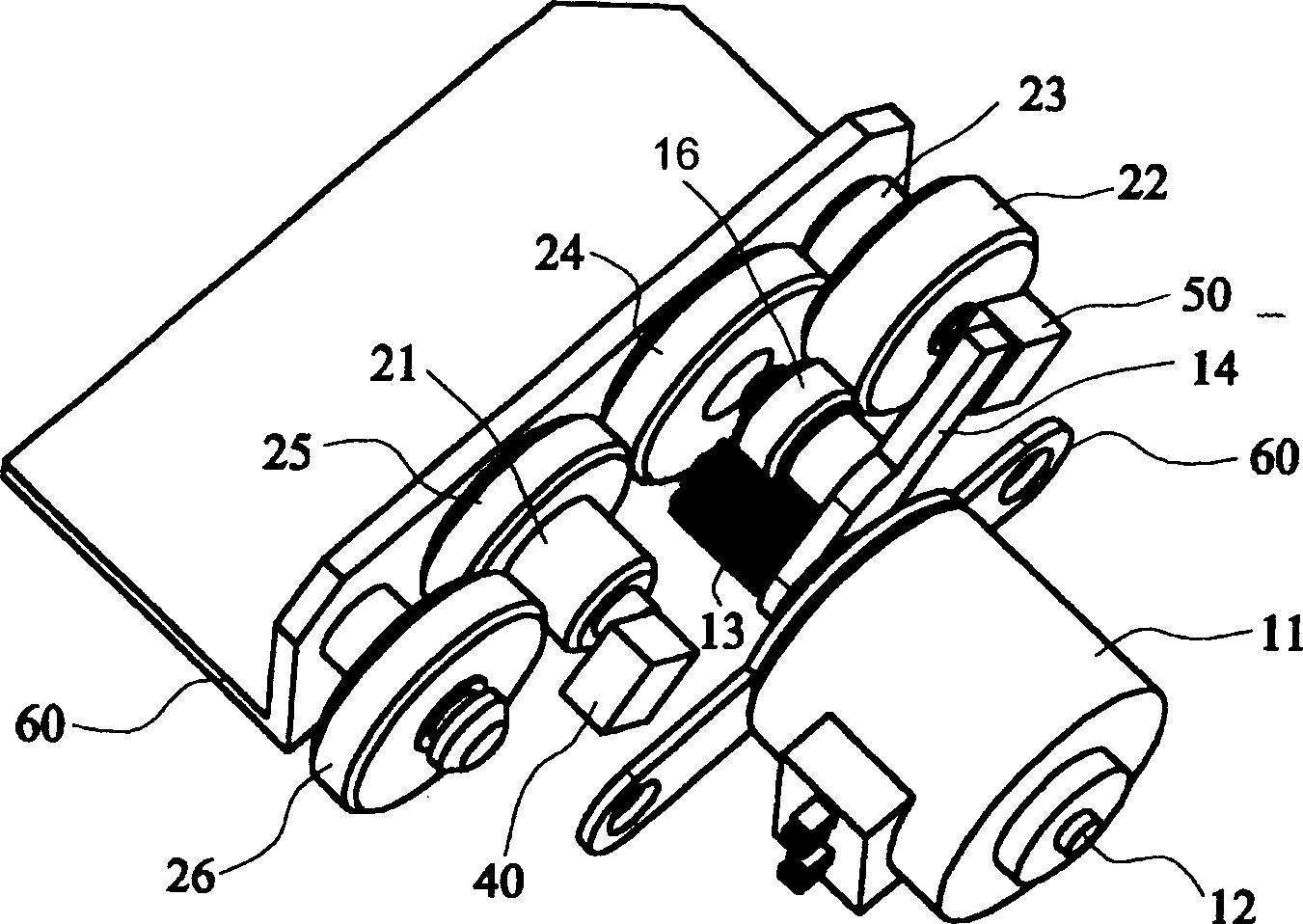

[0022] Figure 5 A schematic top view showing a transmission device with a switchable reduction ratio in a high-speed state according to the second embodiment of the present invention. Such as Figure 5 As shown, the transmission device 10 with switchable reduction ratio of this embodiment includes a motor 11, a driving gear 13, a swing arm 14', a swing arm gear 16, a first gear set 20, a second gear set 30, and a first solenoid valve 41 And the second solenoid valve 51. Some of the above-mentioned components are similar to the first embodiment, so only the differences from the first embodiment will be described below.

[0023] Different from the first embodiment, the swing arm 14' is directly pivoted on the output shaft 12. The first solenoid valve 41 is used to attract the swing arm 14' at the first position P1. The second solenoid valve 51 is used to attract the swing arm 14' at the second position P2. Therefore, this embodiment uses the action principle of the planeta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com