Jelly-roll type electrode assembly, lithium secondary battery having the same, and method for manufacturing the same

A lithium secondary battery and component technology, applied in the field of manufacturing the lithium secondary battery, can solve the problems that cannot be easily installed, the battery cannot be operated well, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

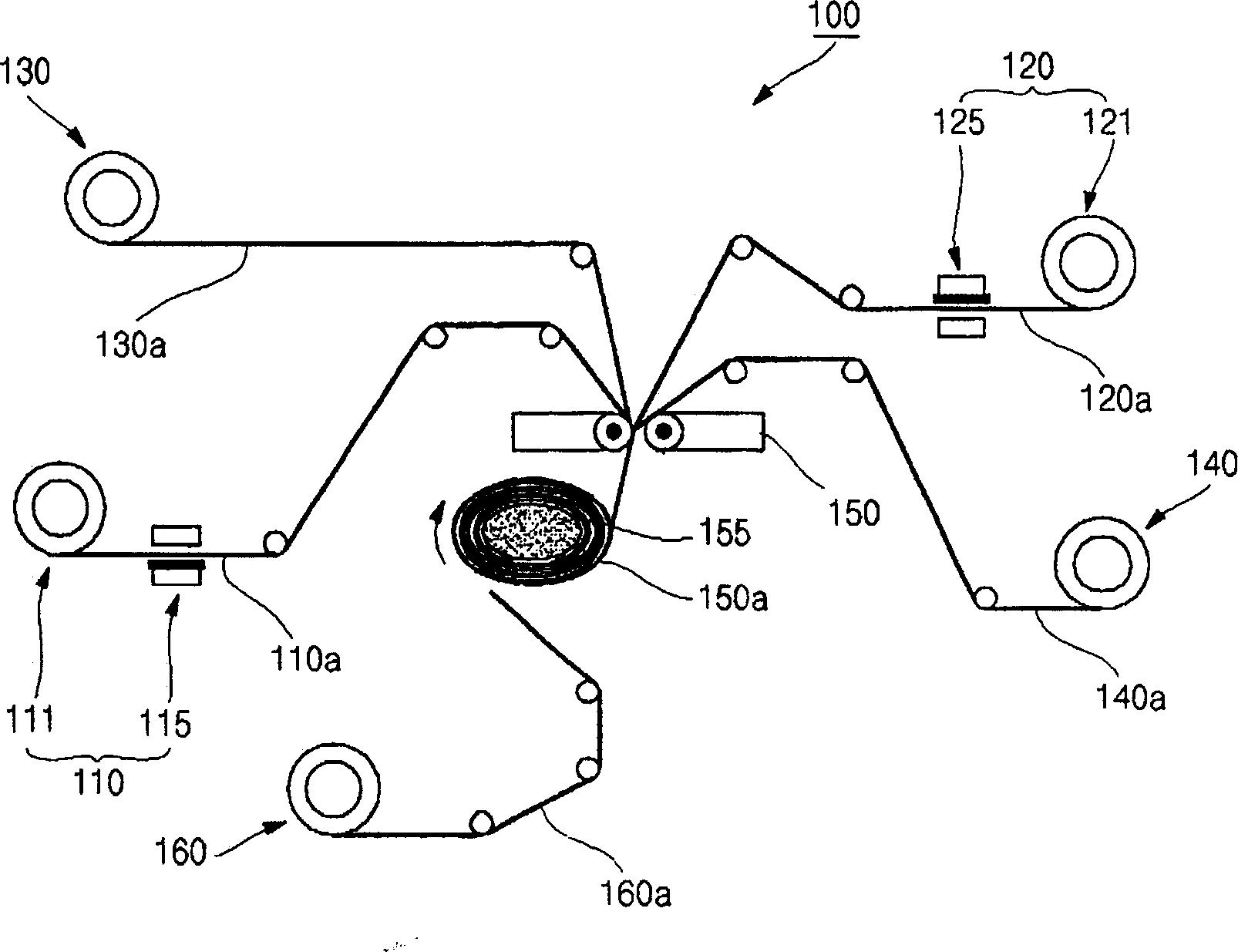

[0031] figure 1 is a schematic diagram of a manufacturing method of a lithium secondary battery according to an embodiment of the present invention. Such as figure 1 As shown, the method includes: first forming the electrode assembly 150a by winding the positive electrode plate 110a, the negative electrode plate 120a, the first separator 130a and the second separator 140a. The positive source 110 provides the positive plate 110a, the negative source provides the negative plate 120a, the first separator source 130 provides the first separator 130a, and the second separator source provides the second separator 140a. The electrode assembly winding device 150 winds the electrode assembly 150 .

[0032] The positive electrode source 110 includes a positive electrode reel 111 for providing a positive electrode plate 110a and a positive electrode tab connection device 115 for connecting a positive electrode tab to the positive electrode plate 110a.

[0033] The negative electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com