Method for measuring relative velocity between medium and surface of metal, and device utilized

A metal surface and relative flow velocity technology, applied in measuring devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve problems such as the method of measuring the scalar flow velocity of the medium that has not been seen, and achieve the simple and easy method of force measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

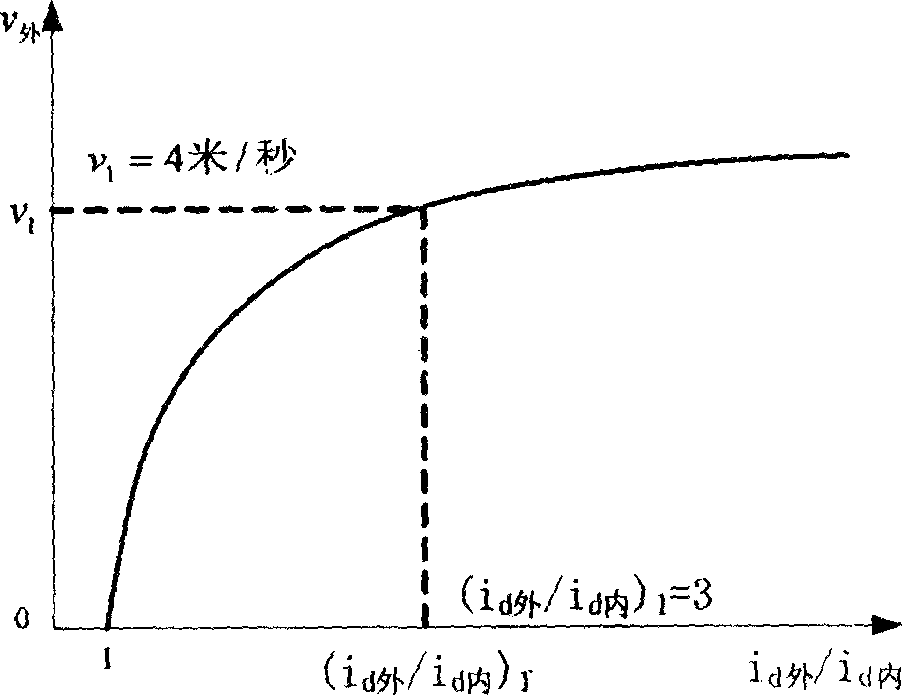

[0011] The limiting current density of the oxygen reduction reaction in the medium is

[0012] i d = nFDδ -1

[0013] where, δ=f(v)i d n is the number of electrons in the oxygen reduction reaction; F is the Faraday constant; D is the diffusion coefficient of oxygen molecules in the medium; δ is the thickness of the diffusion layer, which is a function of the flow rate v. In the formula, n, F, and D are all constants, so the limiting current density i d It is only related to the thickness of the diffusion layer δ. Since the thickness of the diffusion layer δ decreases with the increase of the medium flow rate, the limiting current density i can be determined by d To calculate the thickness δ of the diffusion layer, and then calculate the relative flow velocity on the surface of the medium. The limiting current density i can be obtained by measuring the cathodic polarization curve of the platinum electrode in the medium d .

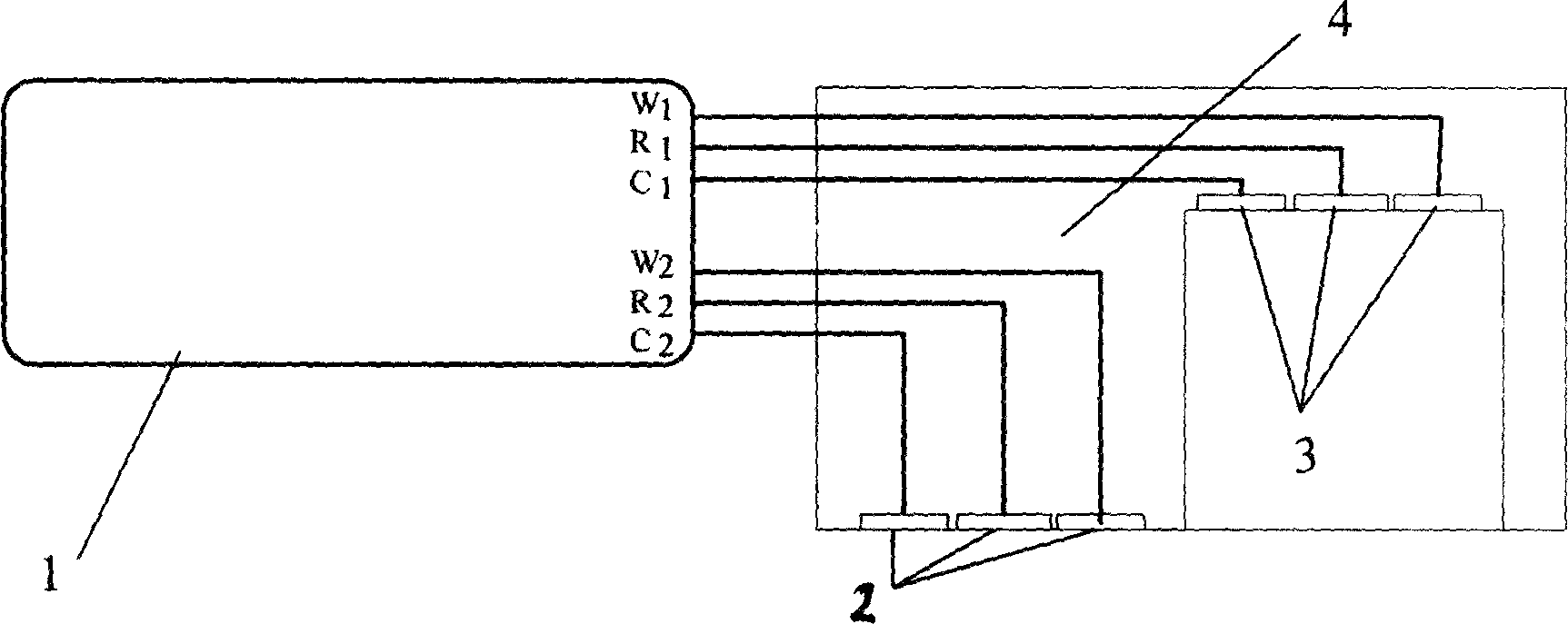

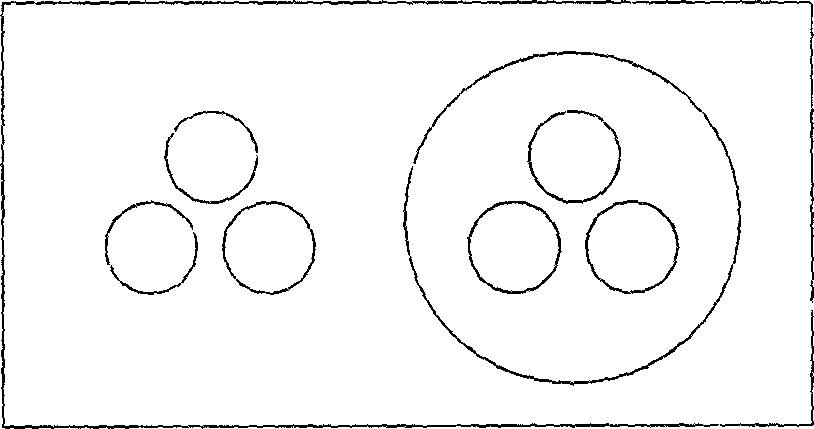

[0014] The device for m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap