Multi-cylinder rotary compressor

A rotary compressor and rotary compression technology, applied in rotary piston machinery, rotary piston pumps, rotary piston/swing piston pump components, etc. Reliability problems and other issues, to achieve the effect of improving compression efficiency and mechanical efficiency, improving reliability and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. The "screws" mentioned in this manual also include small screws and bolts.

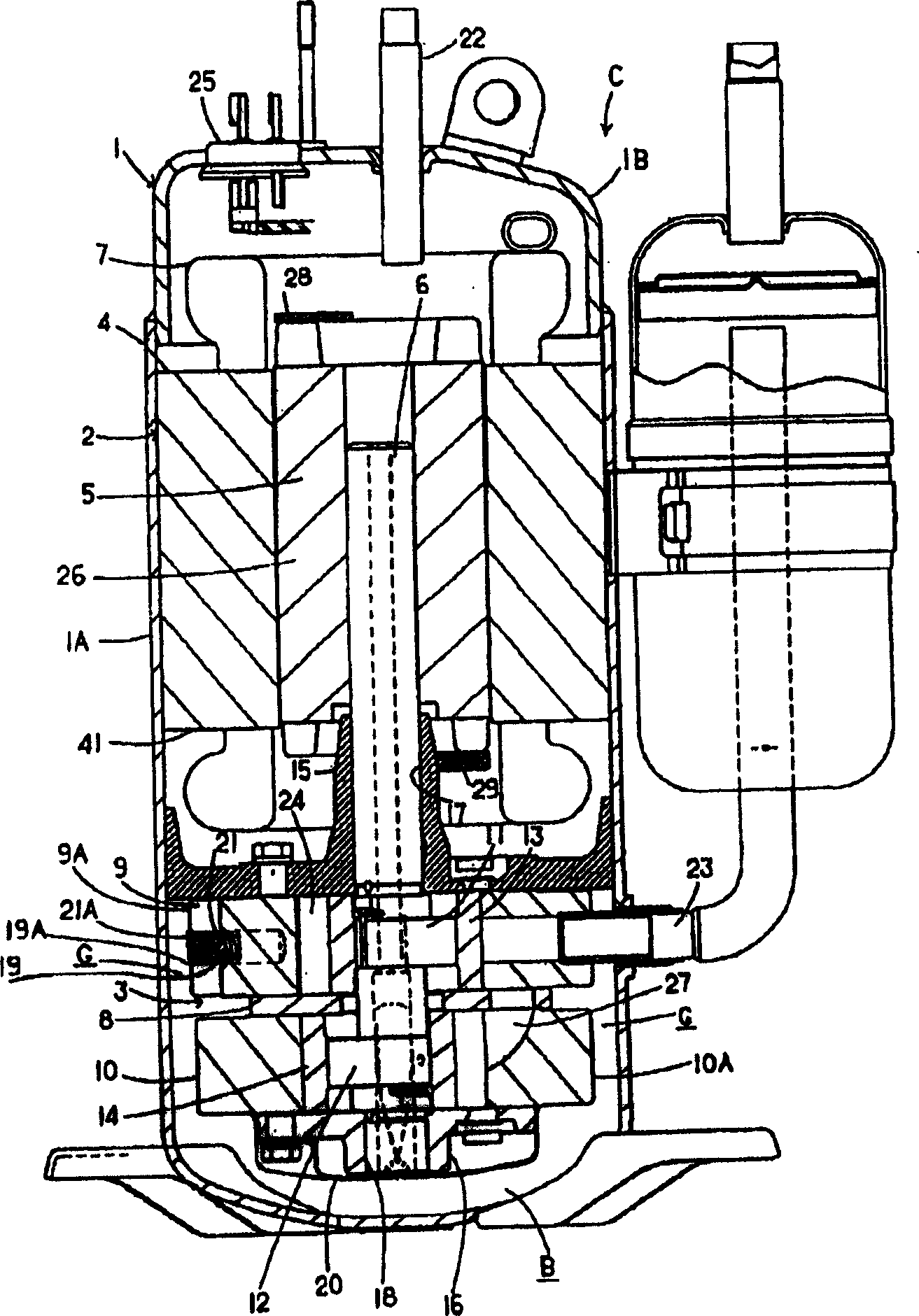

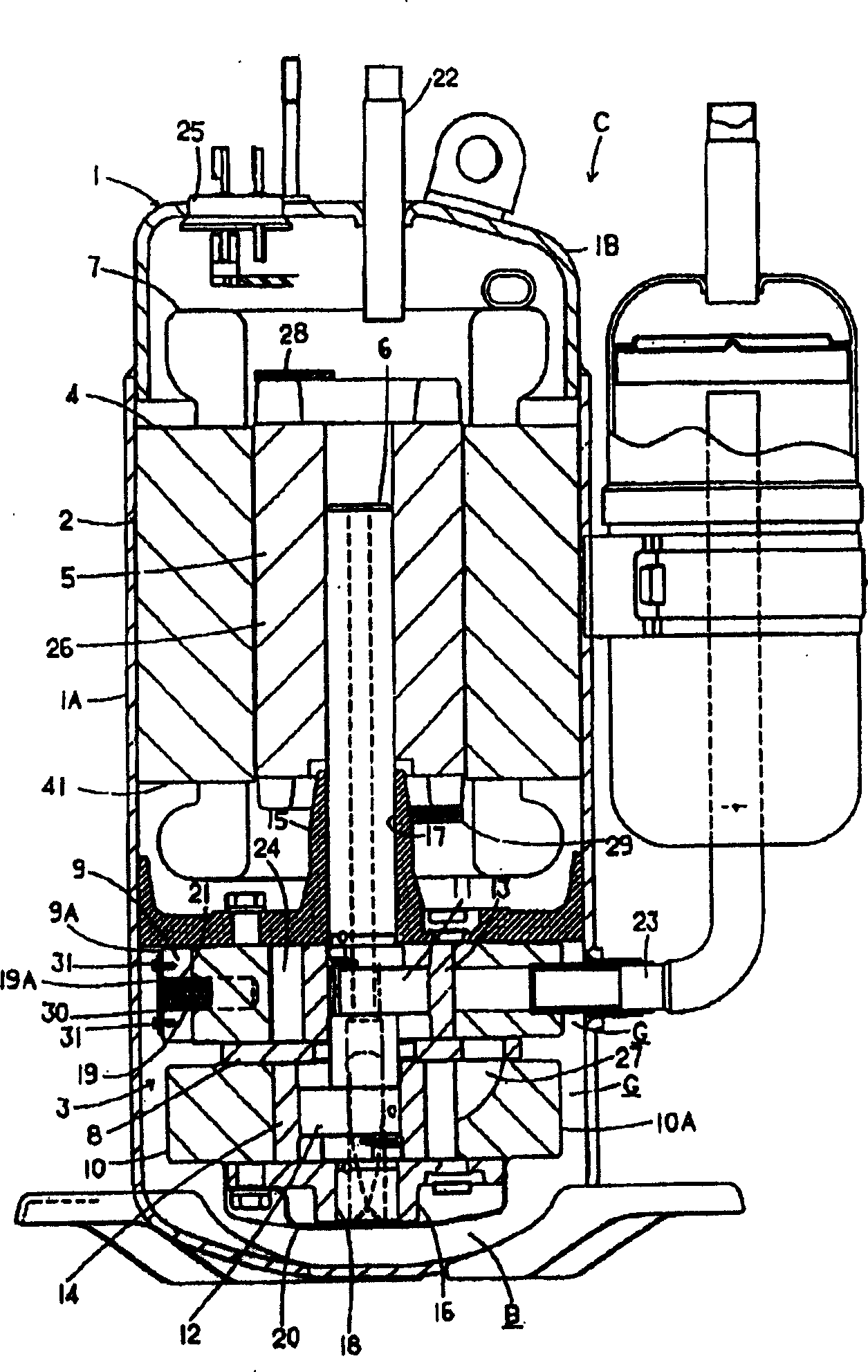

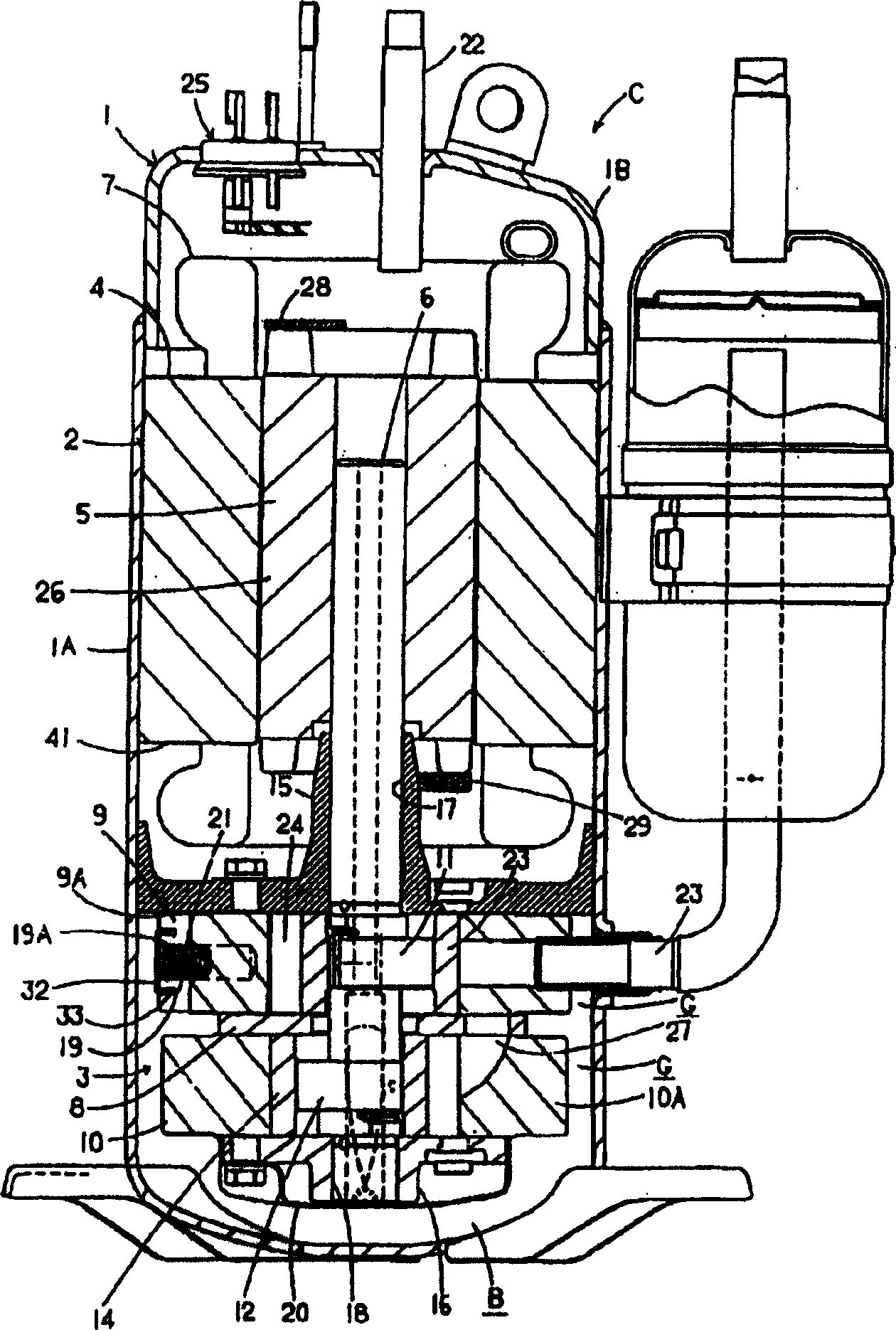

[0028] figure 1 It is a vertical side sectional view of a multi-cylinder rotary compressor C according to an embodiment of the present invention. In the figure, 1 is a cylindrical airtight container, and an electric motor 2 as an electric element is housed in the upper side thereof, and a compression element 3 driven to rotate by the motor 2 is housed in the lower side. The airtight container 1 is composed of two divided parts: a cylindrical case part 1A with an open upper end and an end cap part 1B closing the upper end opening of the case part 1A. After housing the electric motor 2 and the compression element 3 in the casing 1A, the casing 1A is covered with the end cap 1B, and sealed by high-frequency welding or the like. The bottom of the casing portion 1A of the airtight contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com