Driving circuit and driving method for an electrophoretic display

A technology of electrophoretic display and driving circuit, which can be applied to static indicators, instruments, etc., and can solve problems such as appearance dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

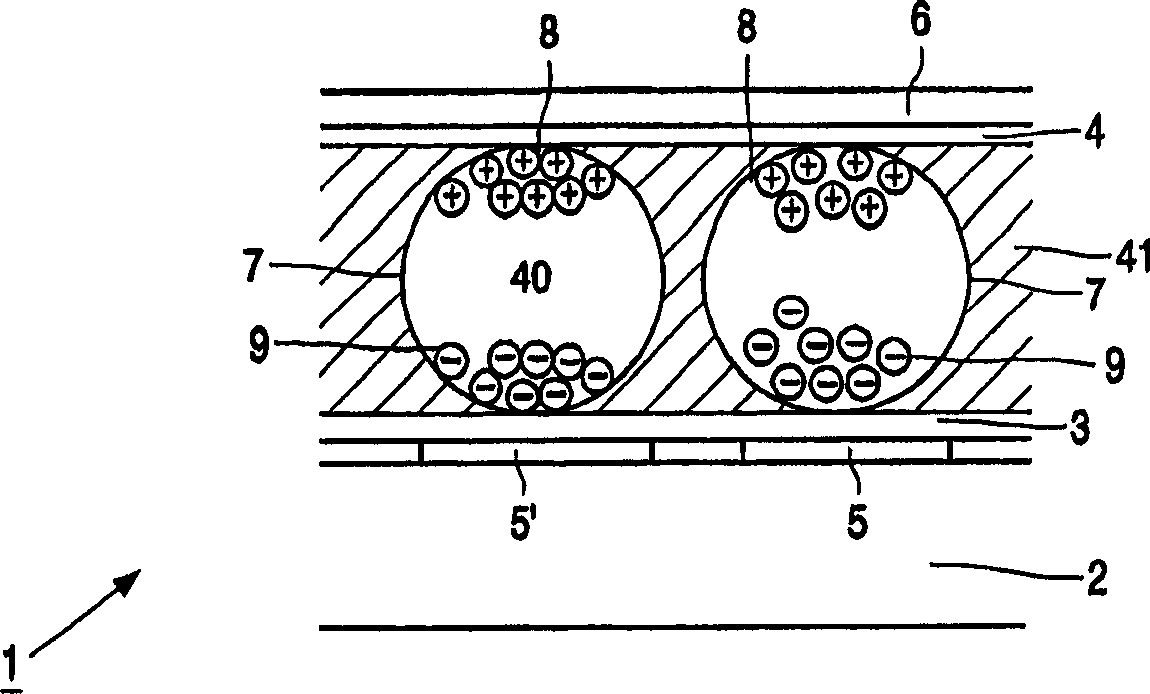

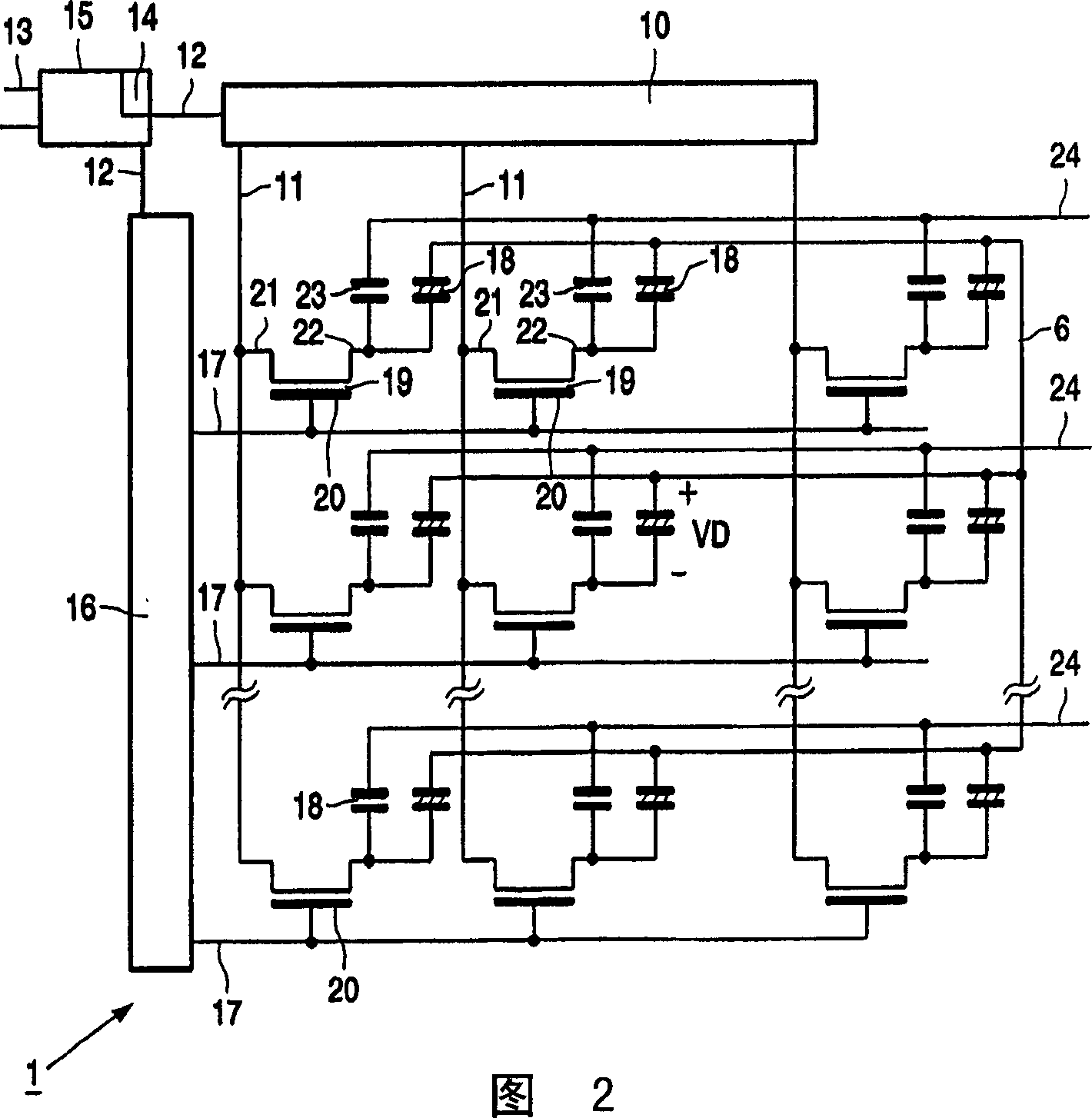

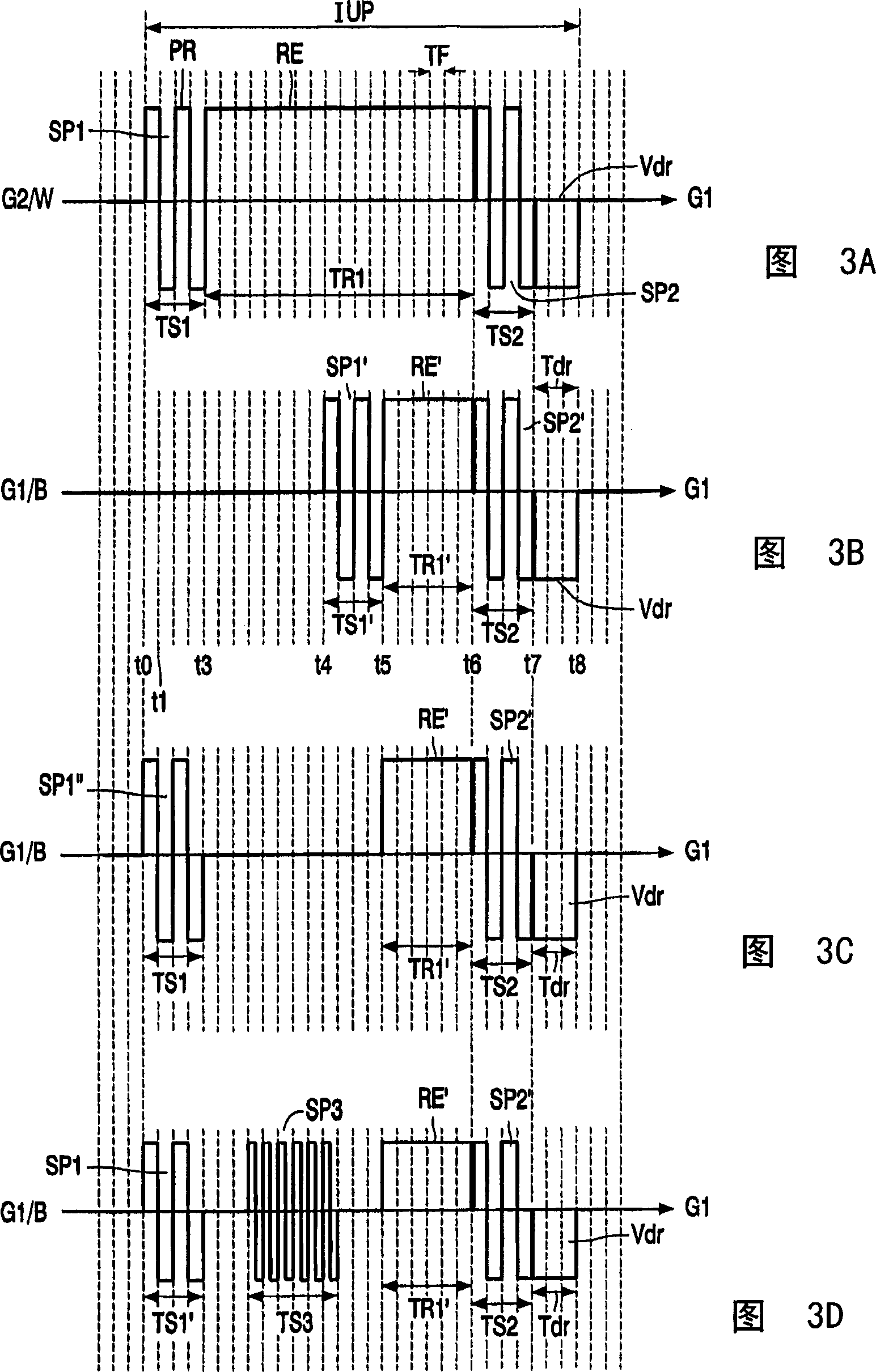

[0032] figure 1Diagrammatically shows a cross-section of a part of an electrophoretic display, for example the size of only a few display elements, comprising a base substrate 2, an electrophoretic film with electronic ink present on two transparent substrates 3 and 4, for example made of polyethylene between. One of the substrates 3 is provided with transparent pixel electrodes 5 , 5 ′, and the other substrate 4 is provided with a transparent counter electrode 6 . The electronic ink includes a plurality of microcapsules 7 of about 10 to 50 microns. Each microcapsule 7 comprises positively charged white particles 8 and negatively charged black particles 9 suspended in a fluid 40 . The hatched material 41 is a polymeric binder. Layer 3 is not required, or may be an adhesive layer. When the pixel voltage VD (see FIG. 2 ) across the pixel 18 is supplied as a positive drive voltage Vdr (see eg FIG. 3 ) to the pixel electrode 5 , 5 ′ opposite the counter electrode 6 , a movemen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap