Rolling-mill housing for rolling bar-type or tube-type rolling piece

A technology of rolling mill stand and tube shape, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems such as the change of side clearance, and achieve the effect of simple moving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

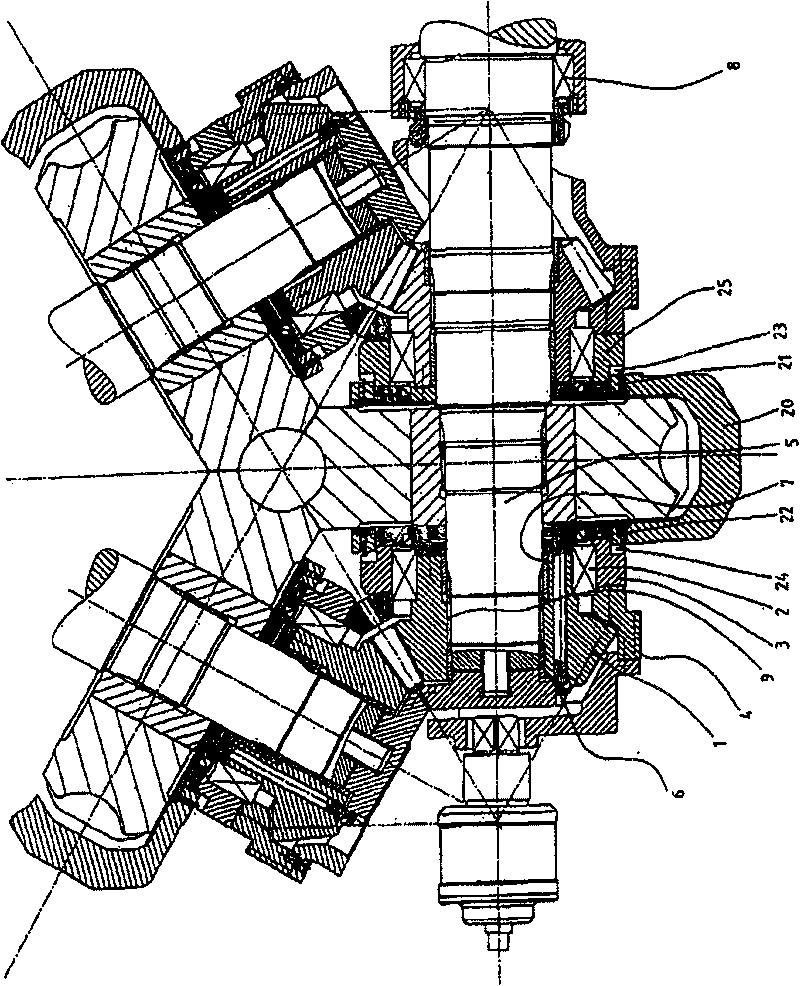

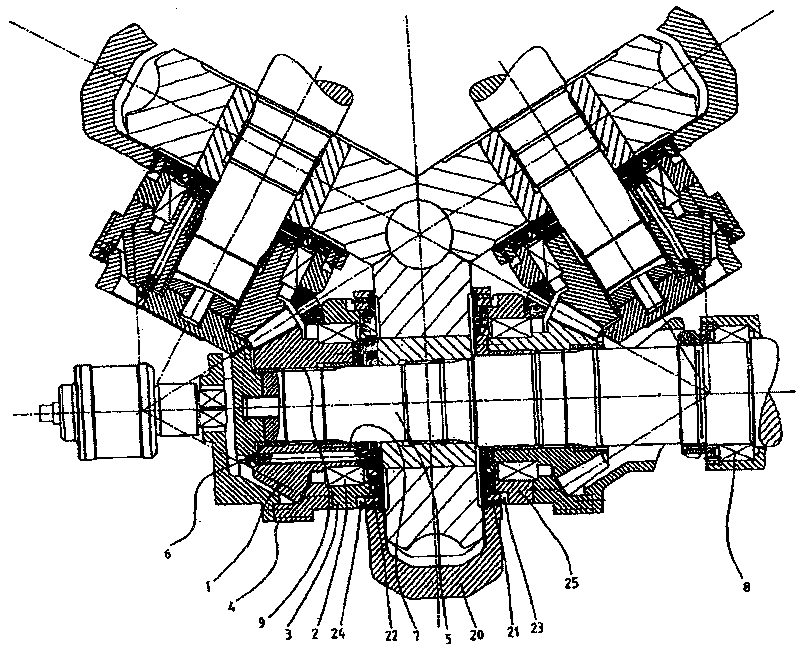

[0016] As can be seen from the drawing, the bevel gear 1 , supported on the eccentric sleeve 3 via rolling bearings 2 , passes through each of the trapezoids arranged on the outside on the eccentric sleeve 3 in a known manner when the eccentric sleeve 3 rotates. Thread 4 moves along the axial direction. The bevel gear thus moves axially on the roller shaft 5 , which is radially supported in the bevel gear via bushings 6 , 7 , but is fixed in its axial position by an axial bearing 8 . The torque is positively transmitted by the roller shaft 5 via the involute mesh 9 to the bevel gear.

[0017] The clip 20 engages via projections 21 , 22 in axially formed grooves 23 , 24 of the eccentric sleeves 3 , 25 . Thus, the rotational movements of these eccentric sleeves are synchronized. However, the eccentric sleeves can be moved axially away from or closer to each other.

[0018] Through this structure, the shaft can be moved precisely and parallel to the axial direction.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap