Headlamp reflector linkage

A technology of reflectors and headlights, which is applied in the directions of headlights, lighting devices, fixed lighting devices, etc., can solve the relative position change of reflectors, the difficulty of precise positioning of high-beam and low-beam reflectors, and the increase of headlight components. issues of cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Referring to FIG. 1 , a headlamp assembly of a motor vehicle 11 is shown generally at 10 . The headlamp assembly 10 provides illumination of the road surface immediately in front of the motor vehicle 11 .

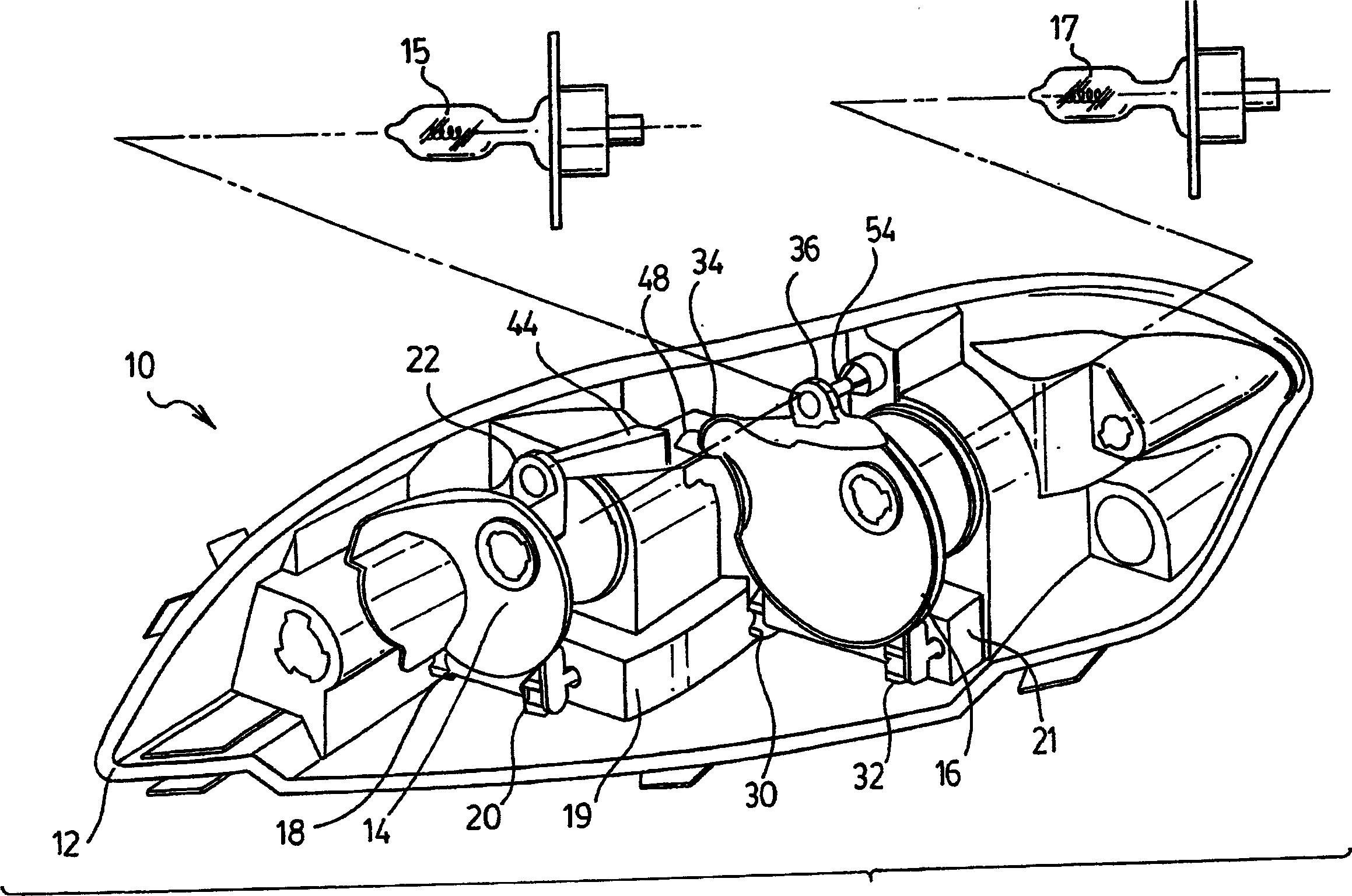

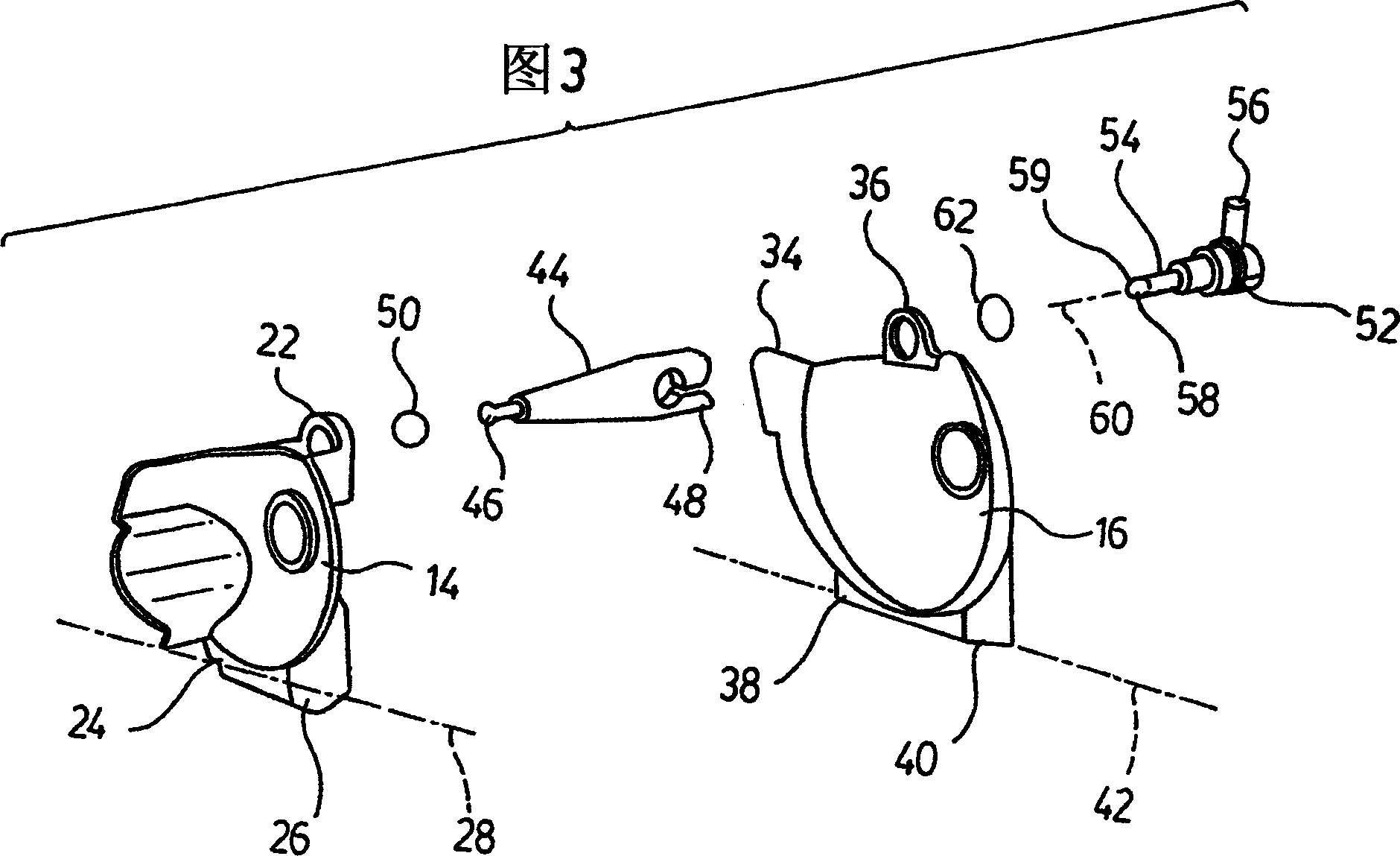

[0012] see figure 2 , the headlamp assembly 10 includes a cover 12 . The headlamp assembly 10 also includes a first reflector 14 and a second reflector 16 disposed within the cover 12 . In a preferred embodiment, the first reflector is a high beam reflector 14 and the second reflector is a low beam reflector 16 . The bulbs 15 and 17 are mounted in each of the high beam reflector 14 and the low beam reflector 16 . The high beam reflector 14 and the low beam reflector 16 focus and align the light emitted by the electric lamp.

[0013] The cover 12 is generally concave and is molded to provide mounting surfaces for the light reflectors 14,16. Additionally, the housing 12 is configured such that a light bulb or other suitable light source may be mounted thereon. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com