Horizontal milling-boring machine with mobile column

A technology for milling, boring and machine tools, which is applied to metal processing mechanical parts, large fixed members, manufacturing tools, etc., and can solve problems such as high cost and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

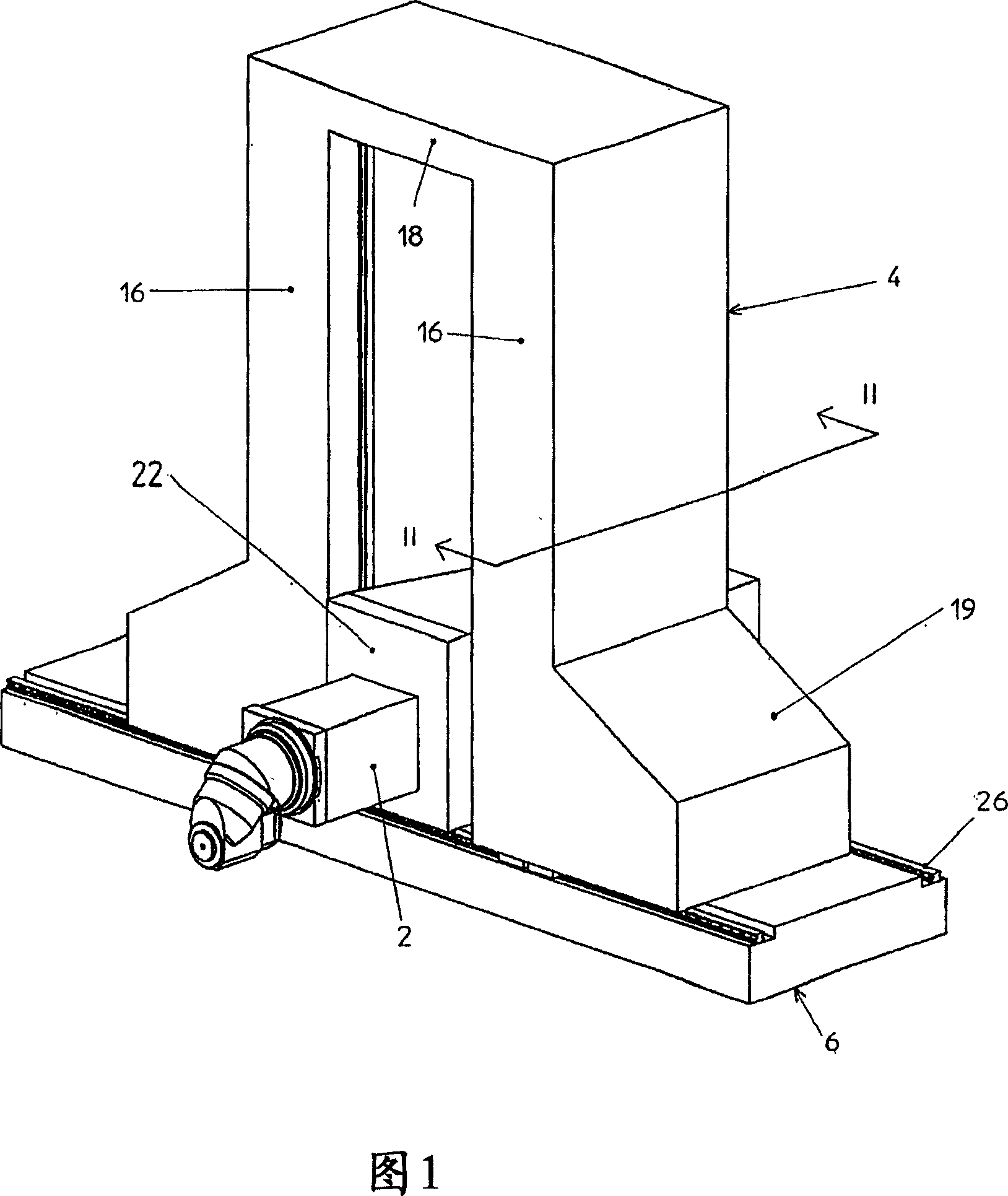

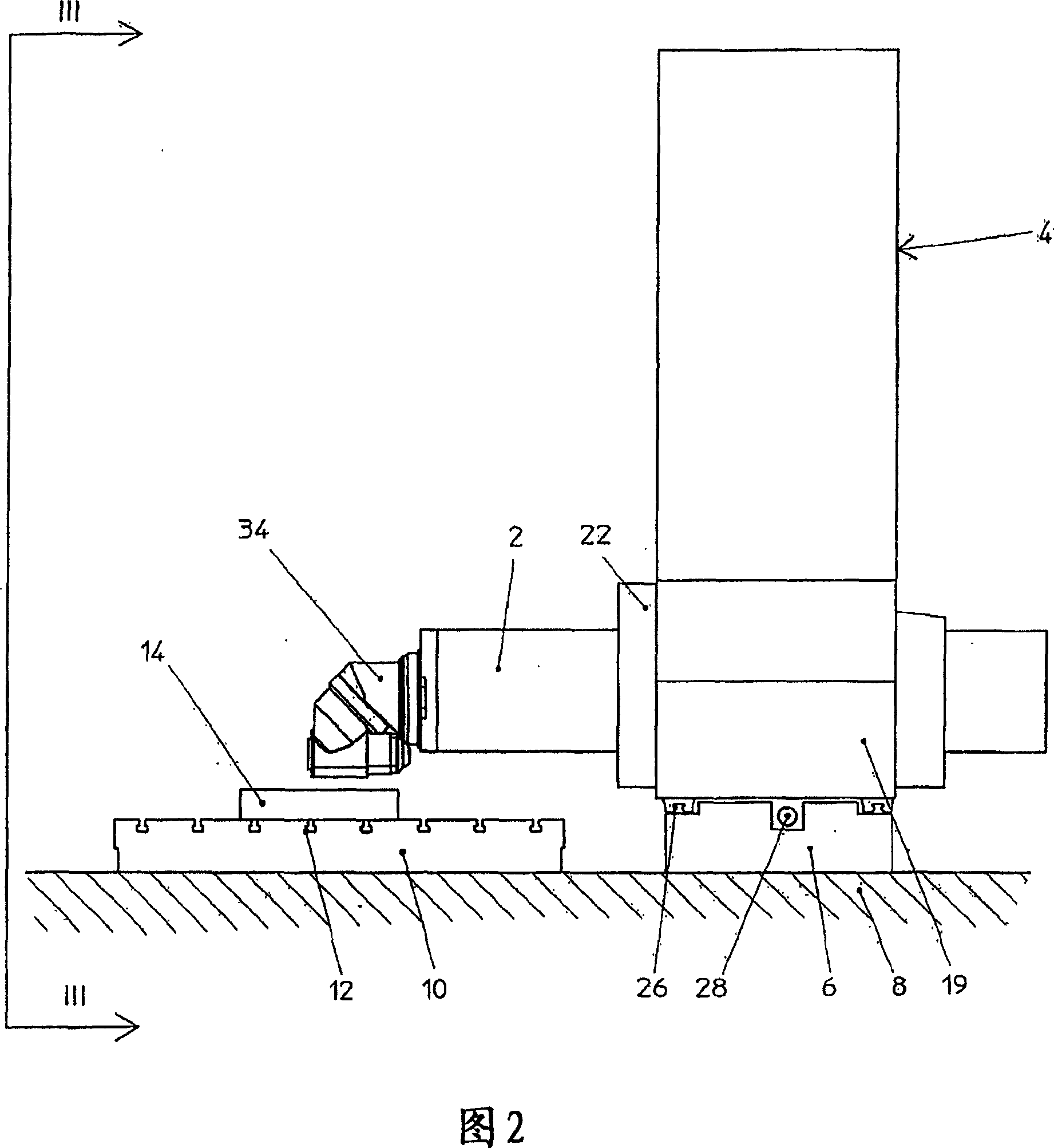

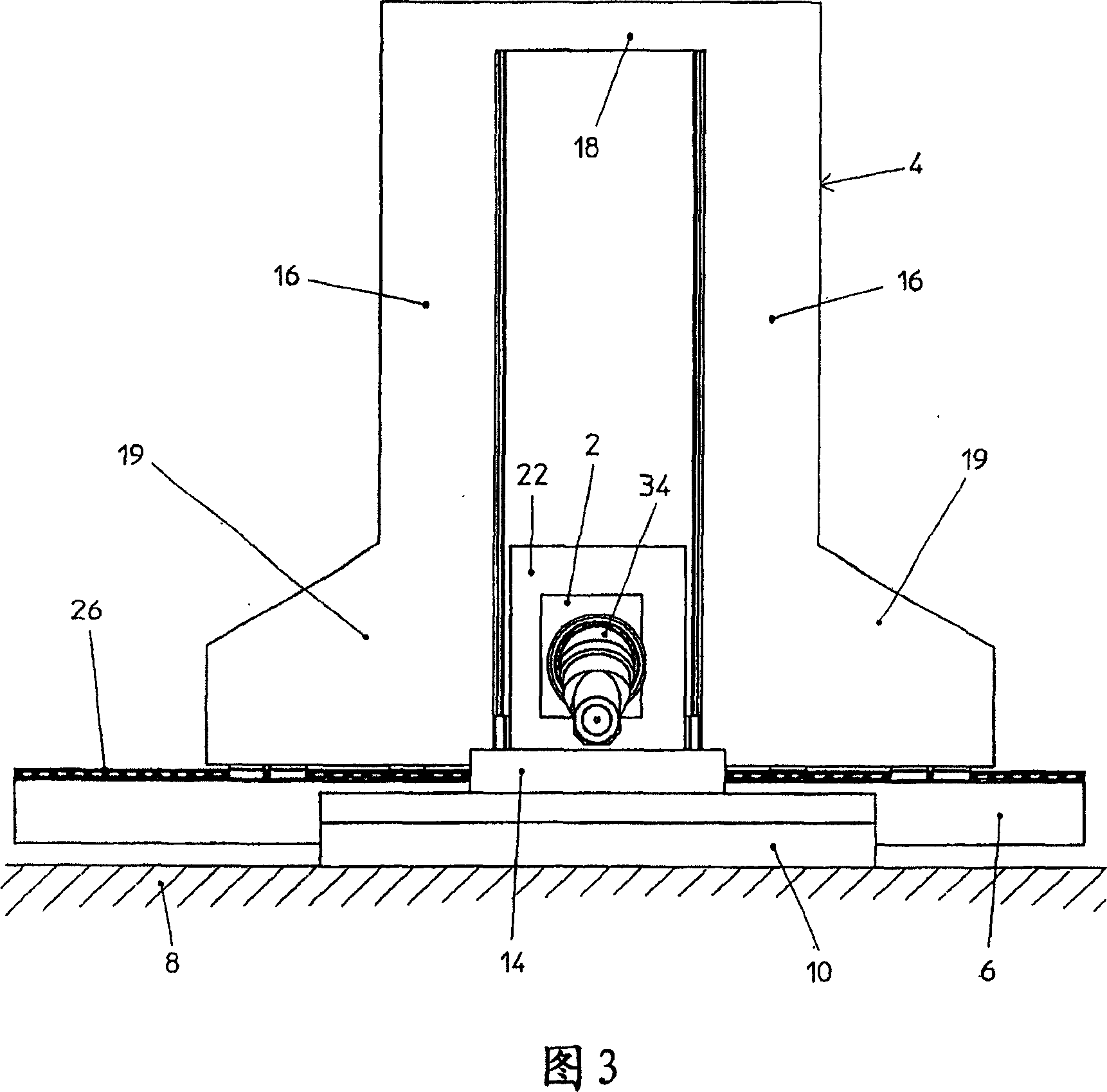

[0024] As shown in FIGS. 1-4 , the first embodiment of the milling-boring machine tool of the present invention is basically a known moving column machine tool, that is to say with a machine tool that can move axially and also vertically along the column structure 4 . The moving horizontal sliding seat 2 , the column structure itself moves horizontally along the base 6 in a direction perpendicular to the axis of the sliding block 2 , and the base 6 is anchored on the floor 8 .

[0025] More particularly, not only the base 6 is anchored to the floor 8, but also the table 10, which is separate from the base and has a recess 12, where the workpiece 14 to be machined is fixed in a conventional manner on the floor 8. On stage 10.

[0026] The column structure 4 is a symmetrical gantry type and includes a pair of columns 16. The upper part of the column 16 is connected to each other by a beam 18 and is extended into a pair of parts 19 at the lower part. The column structure on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com