Wobbler type external quick action equipment for pipe orifice connecting

A technology of eccentric wheel and mouthpiece, which is applied in the direction of workpiece clamping device and manufacturing tool, can solve the problems of long operation time, need of power supply, inconvenient operation, etc., achieve accurate concentricity alignment, rapid correction of nozzle, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

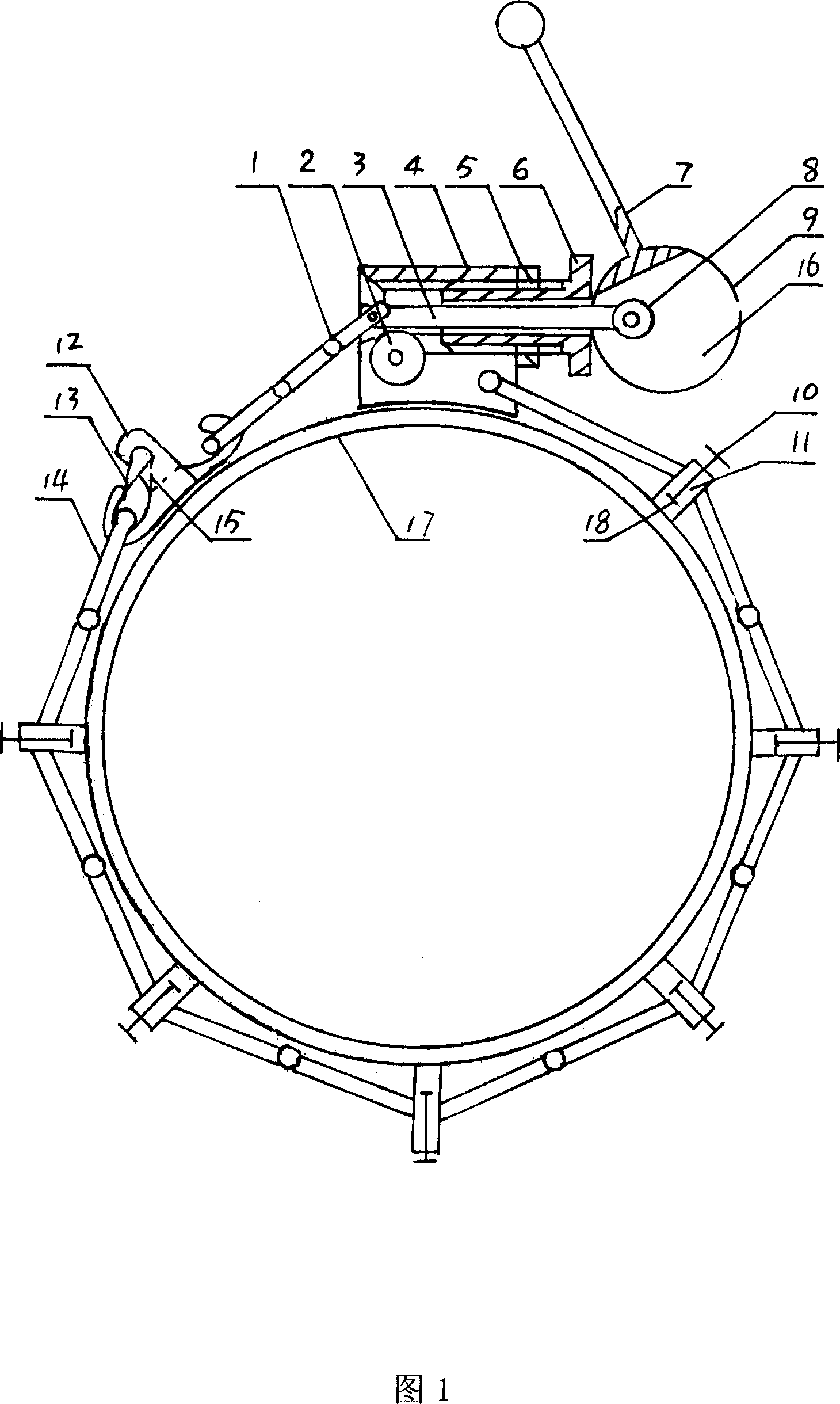

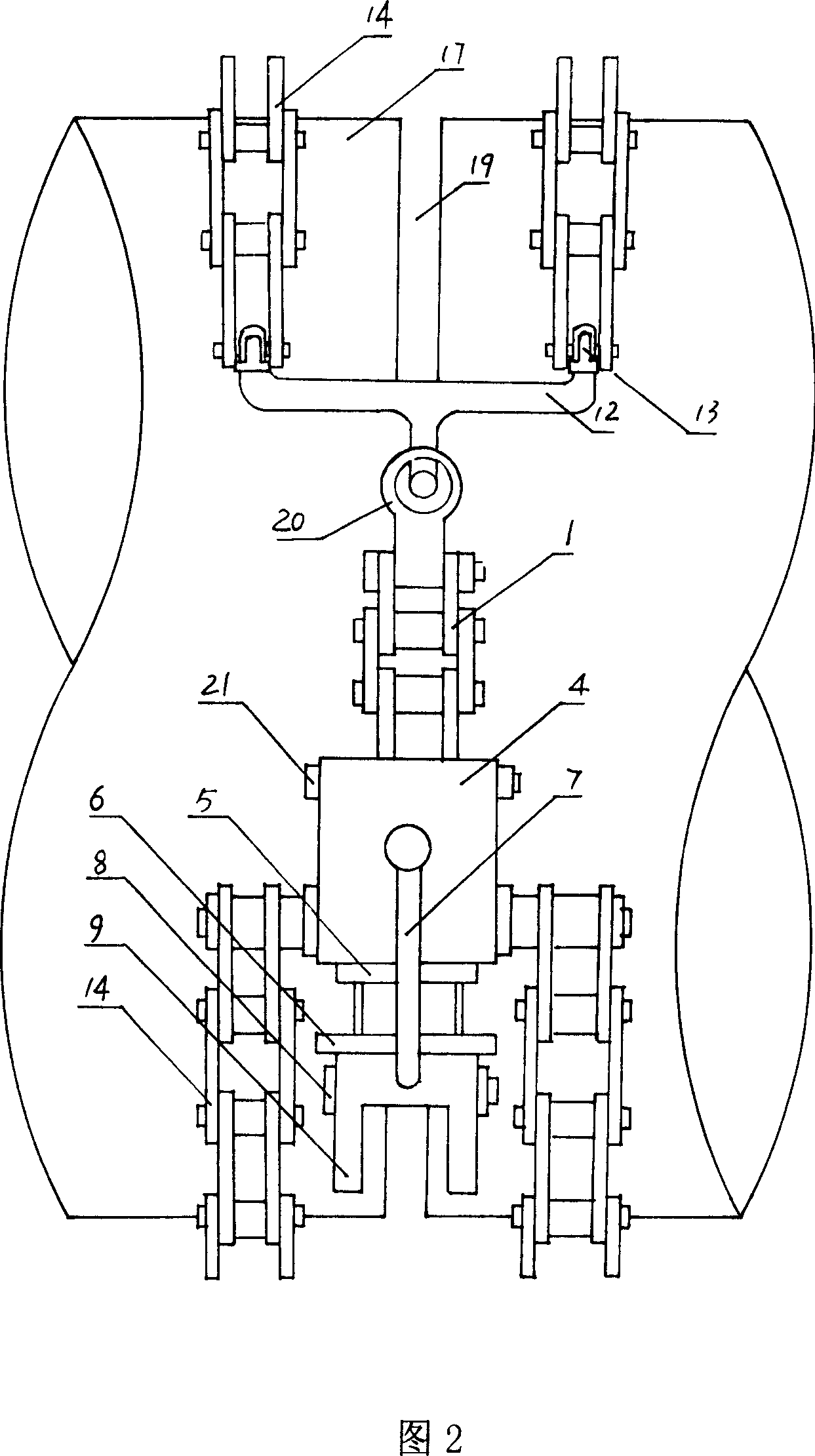

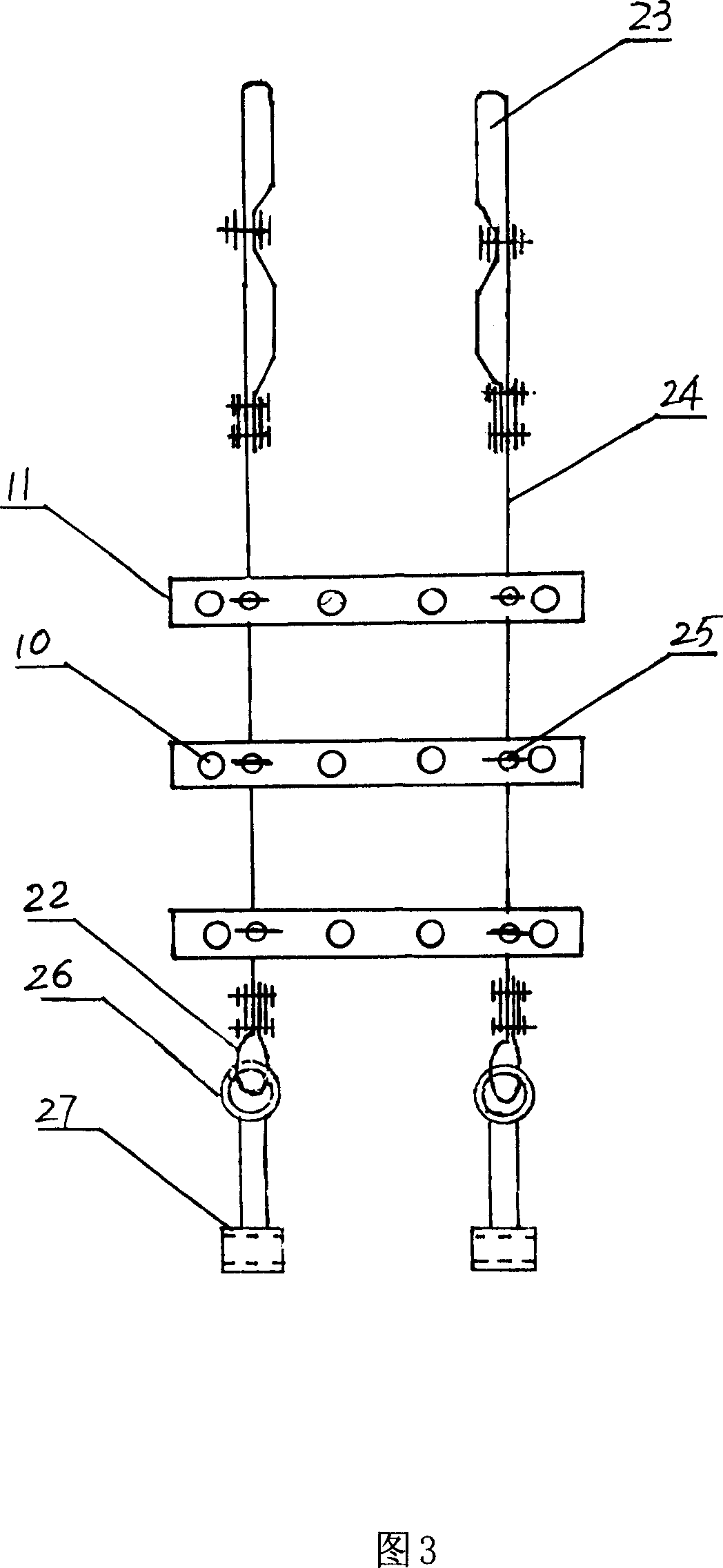

[0040] With reference to the accompanying drawings, the present invention will be further described in accordance with the sequence of figures. Fig. 1, an adjusting screw sleeve 6 is installed in the mounting seat 4, and a pull rod 3 is installed in the adjusting screw sleeve 6, and one end of the pull rod 3 is connected with a short chain 1 or a wire rope 24, and the other end is used The movable hinge 8 is connected in the middle groove 16 on the radial side of the eccentric wheel 9, the movable hinge 8 is located outside the radial center of the eccentric wheel 9, the eccentric wheel 9 is equipped with an operating rod 7, a pair of chains 14 or a pair of wire ropes 24 Separately and flexibly connected to both sides of the bottom corner of the right end of the mounting base 4, the pair of chains 14 or a pair of steel wire ropes 24 are equipped with a correcting part 11, and the other ends are respectively connected to two symmetrical hooks of the three hooks 12, which are loos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com