Rack-and-pinion type outer pipe quick aligner

A rack-type and mouth-to-mouth technology, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inconvenient work movement, long operation time, and large equipment, and achieve convenient and labor-saving operation and correct tube Fast and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

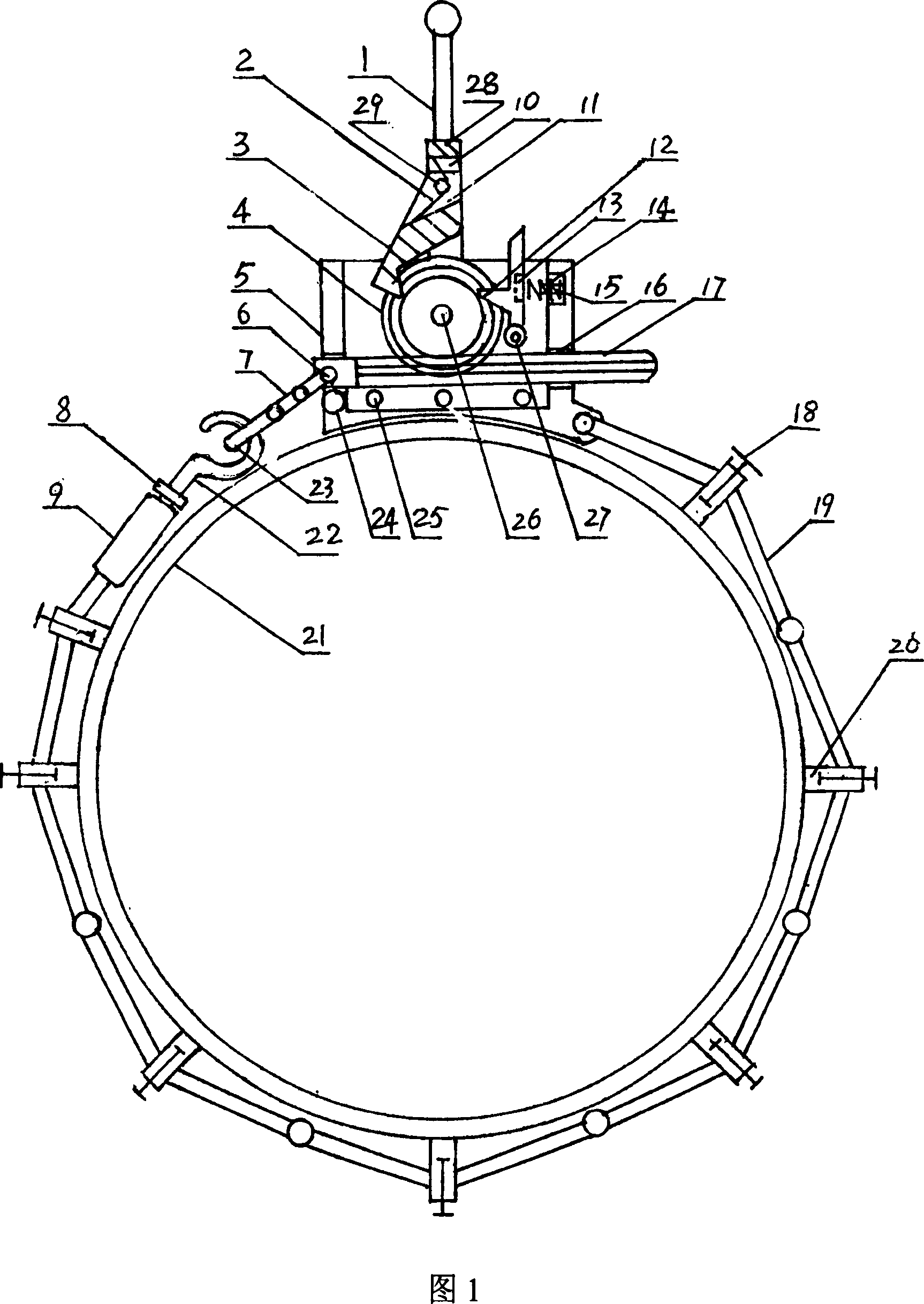

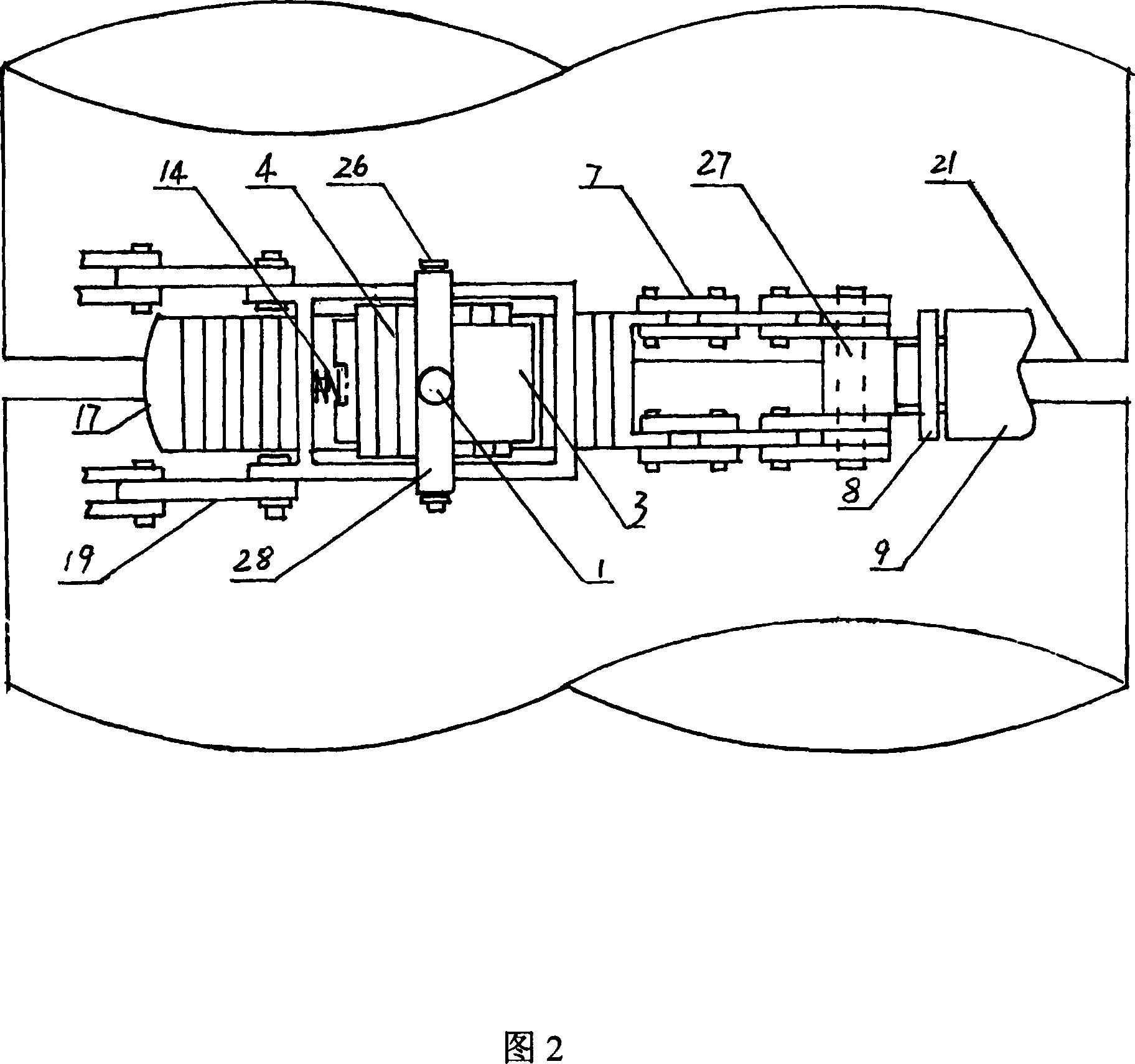

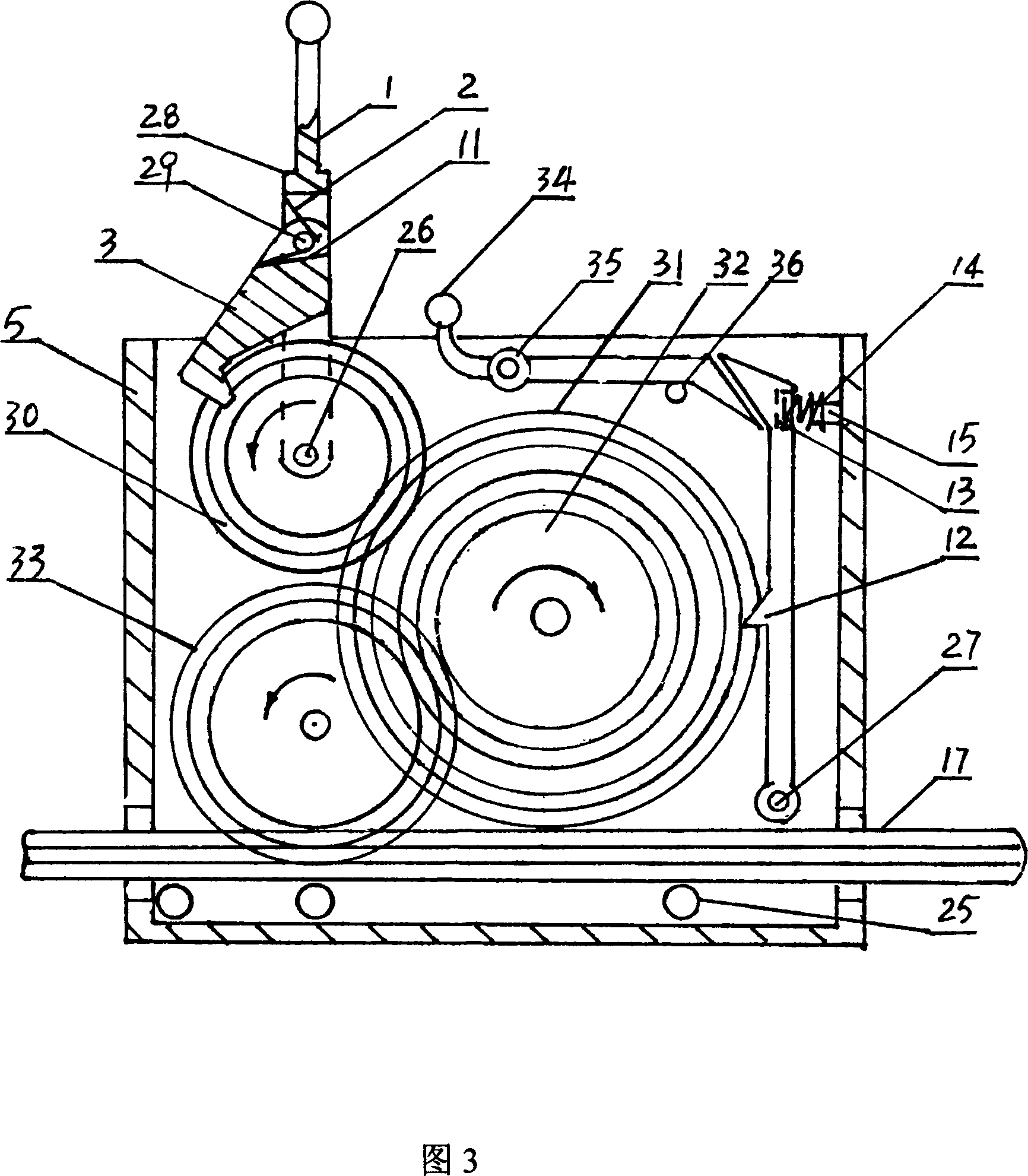

[0035] Fig. 1, when in use, the pipe outer mating device is placed on the top of the pipe (21), in the middle of the two pipe welds, then the chain (19) connected to one end of the assembly box (5) is wound around the pipe, and the retractable end of the chain is used to Hook (22) is hung in the connecting ring (23) of short chain (7), moves operating handle (1) and makes dial claw (3) pushes gear (4) to rotate, and gear (4) stirs tooth bar motion and Shrink the chain, and the correction plate (20) on the chain forces the two pipes (21) to be pressed on the same axis, so as to achieve the purpose of aligning the pipe. If the nozzle has been deformed, use the correction bolt (18) on the correction plate (20) ) for correction, when moving the operating handle (1) to make the gear rotate, the brake pawl control gear does not reverse, the pipe matching ends, and when the pipe matching device is removed, moving the operating handle (1) backward is more than normal operation Pull so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com