Ink ribbon preventing skip and heat transfer-printing image-forming device

A technology of an imaging device and a printing device, which is applied in the directions of printing devices, inking devices, ink ribbons, etc., can solve problems such as waste of ink ribbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Matters defined in the specification, such as detailed construction and elements, are provided to assist in a comprehensive understanding of the embodiments of the present invention, and are exemplary only. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. In addition, descriptions of well-known functions and constructions are omitted for clarity and conciseness.

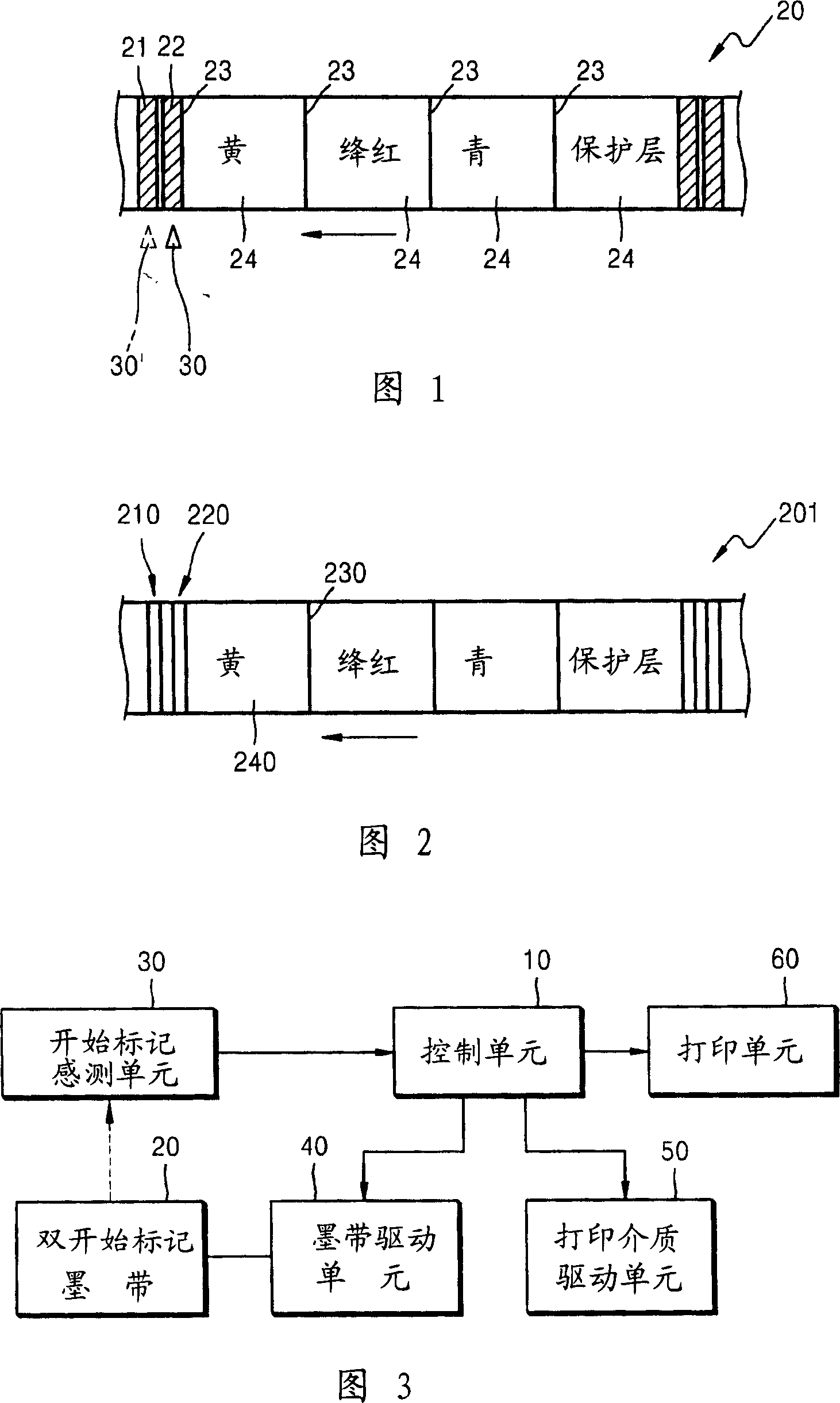

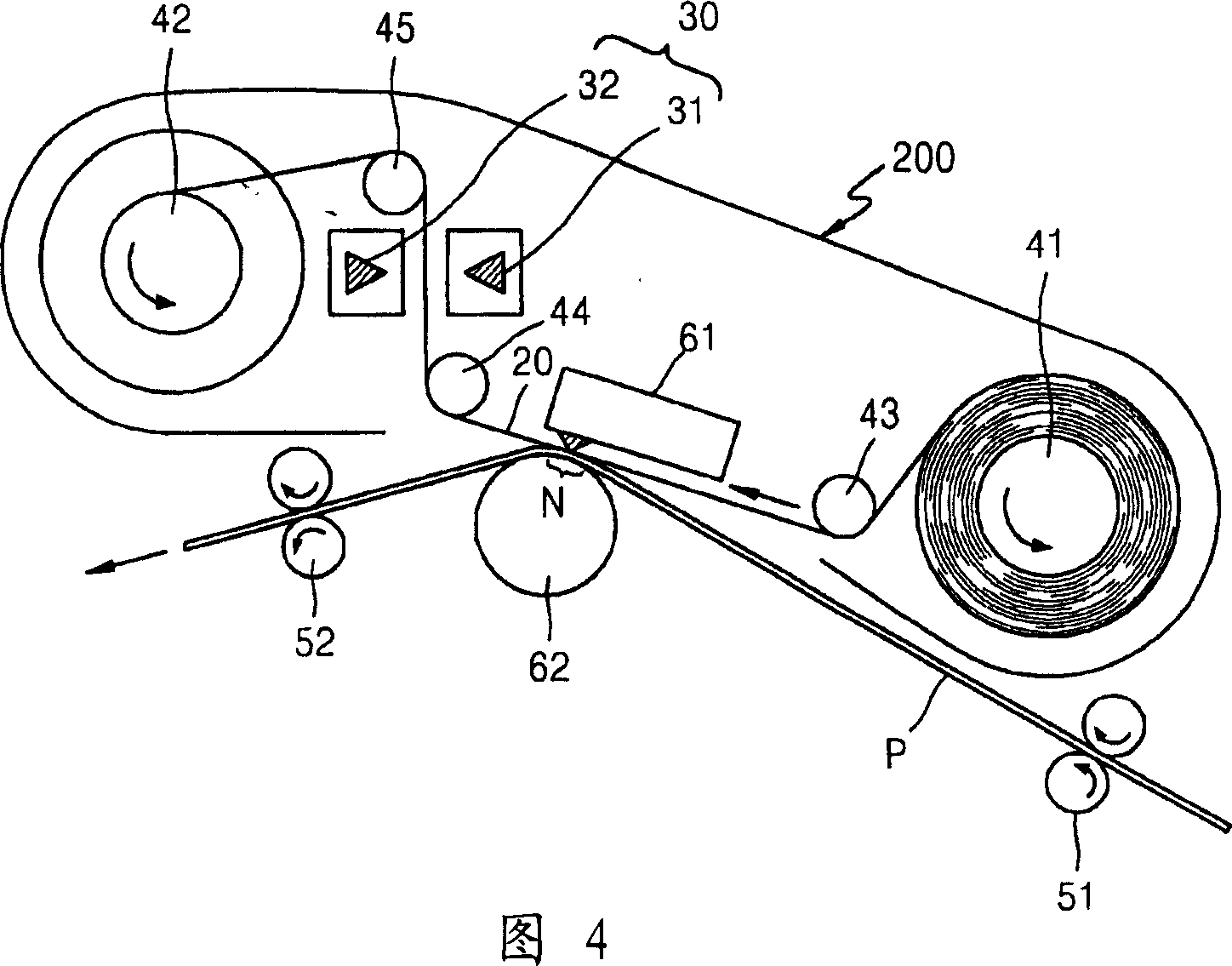

[0020] The features of the invention are now explained by way of exemplary embodiments with reference to the accompanying drawings. FIG. 1 is a schematic layout diagram of an ink ribbon 20 according to an exemplary embodiment of the present invention. The ink ribbon 20 for a thermal transfer type image forming apparatus includes a plurality of printing areas formed to perform a plurality of printing cycles. The print area can be repeatedly formed. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap