Constitution of automatic rolling-up tapeline causing case contraction, weight lightening and strip lengthen

An automatic rewinding and lightweight technology, which is applied to measuring devices, bendable rulers, instruments, etc., can solve the problems that the volume cannot be reduced, it is not easy to grasp, and it cannot meet the needs of users, such as simplicity and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The first embodiment:

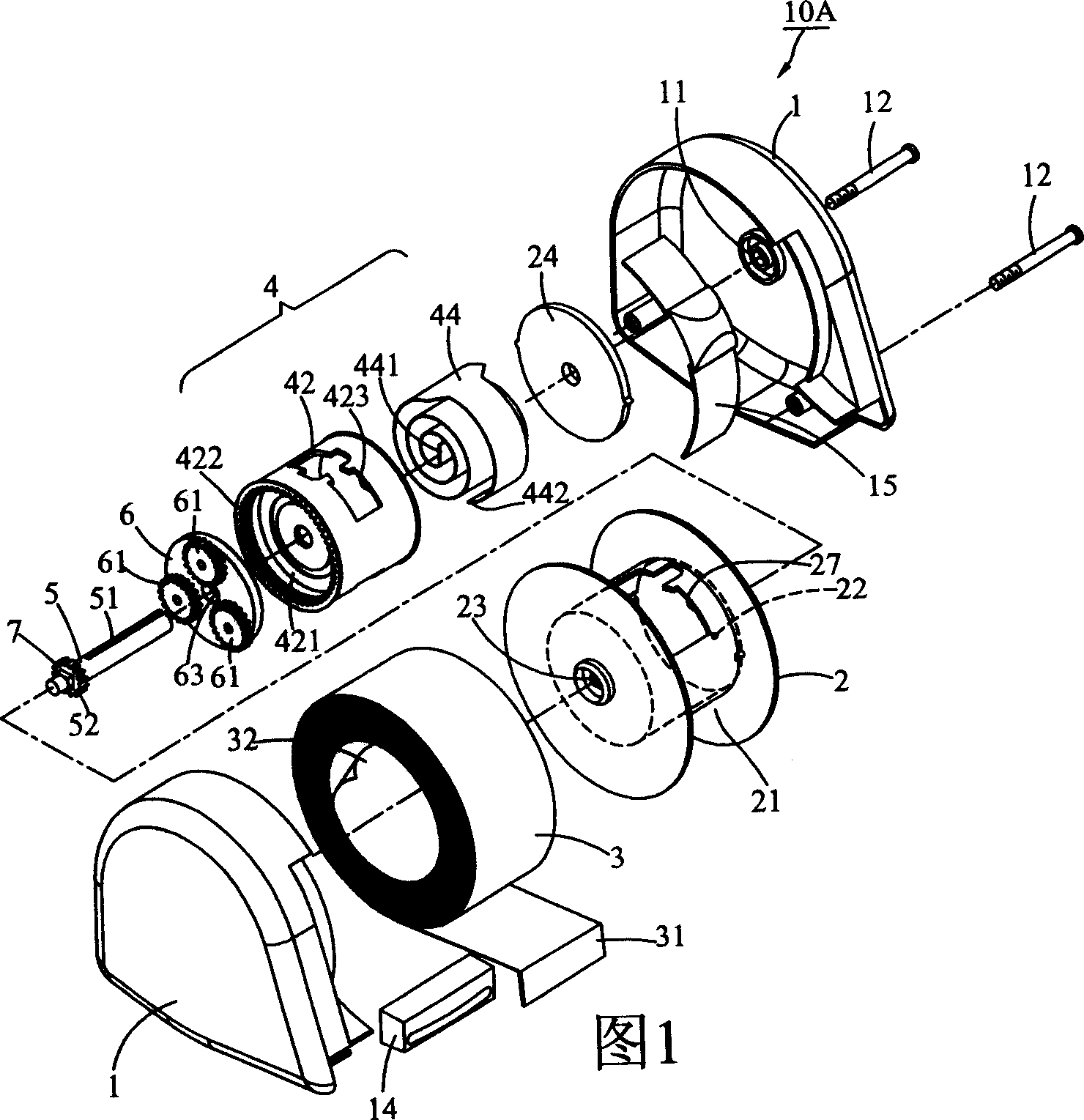

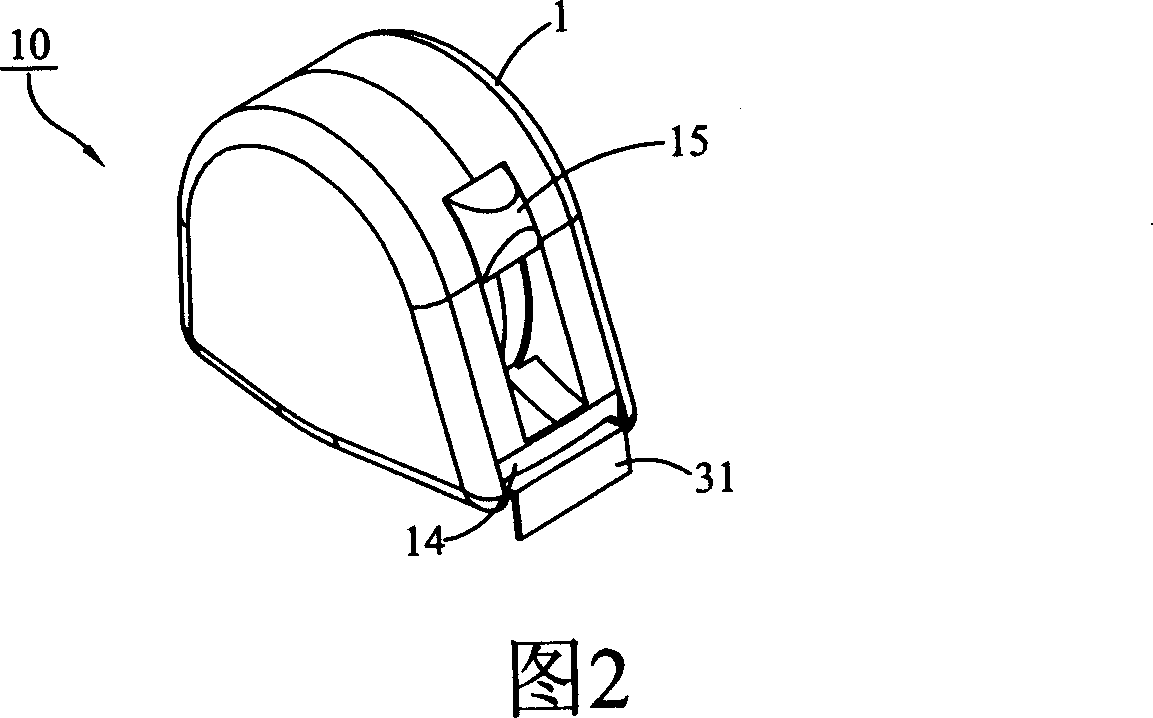

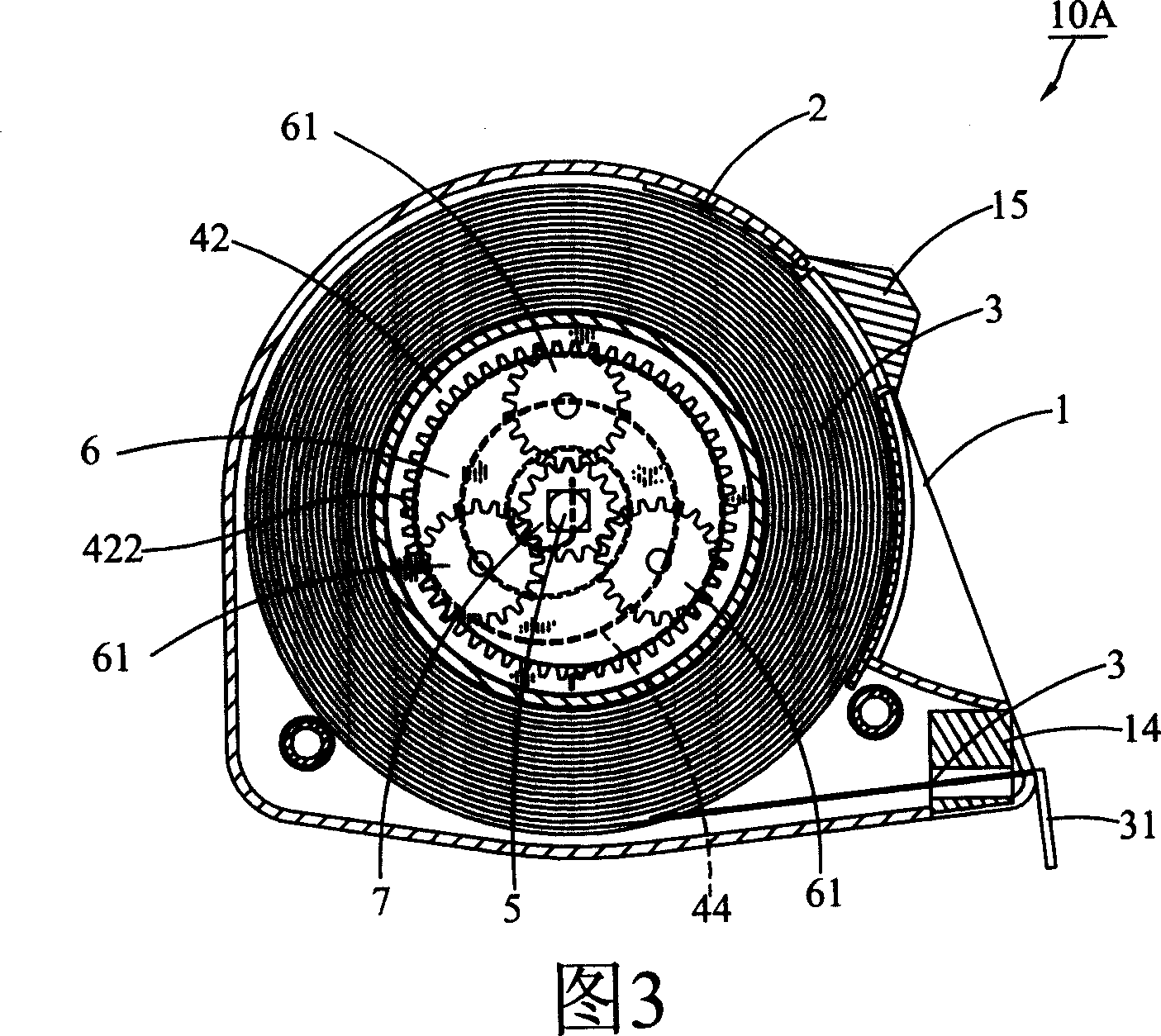

[0053] Figures 1 to 3 are three-dimensional exploded views, three-dimensional assembled views, and full sectional views of the tape measure in the first embodiment of the present invention, in which a tape measure 10A is disclosed, which includes a ruler shell 1, which is a hollow shell; a roll Cylinder 2, arranged in the scale shell 1, has a groove 21 on its periphery and a cylinder groove 22 inside; a ruler strip 3 is wound in the groove 21 of the reel 2; a rotating shaft 5 is axially arranged on the reel 2 in the center of the cylinder groove 22; a winding device 4, a reel 42 is arranged in the cylinder groove 22 of the reel 2, and the side of the reel 42 is provided with a containing groove 421 and has an inner ring tooth 422 in the groove, and A scroll spring 44 is arranged in the scroll wheel 42, and the outer end 442 of the spring is fixed in the scroll wheel slot 423; a rotating shaft 5 axially shuttles in the inner center of the scroll w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com