Magnetic head and manufacturing method therefor

a manufacturing method and head technology, applied in the field of magnetic head, can solve the problems of generating noise, difficult to form magnetic metal films facing each other on a sole substrate, and difficulty in coping with digital picture recording

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Referring to the drawings, preferred embodiments of a magnetic head according to the present invention will be explained in detail.

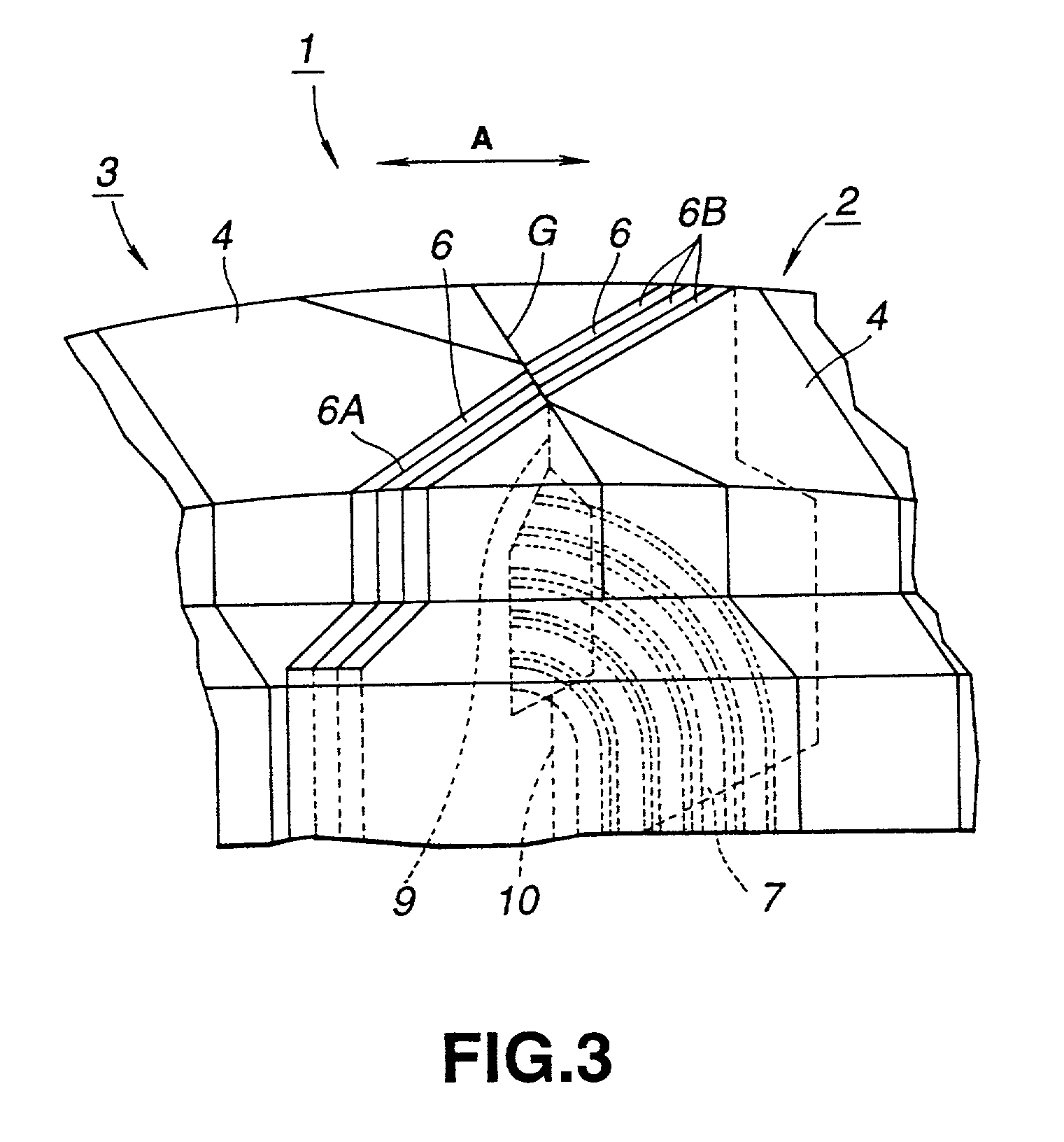

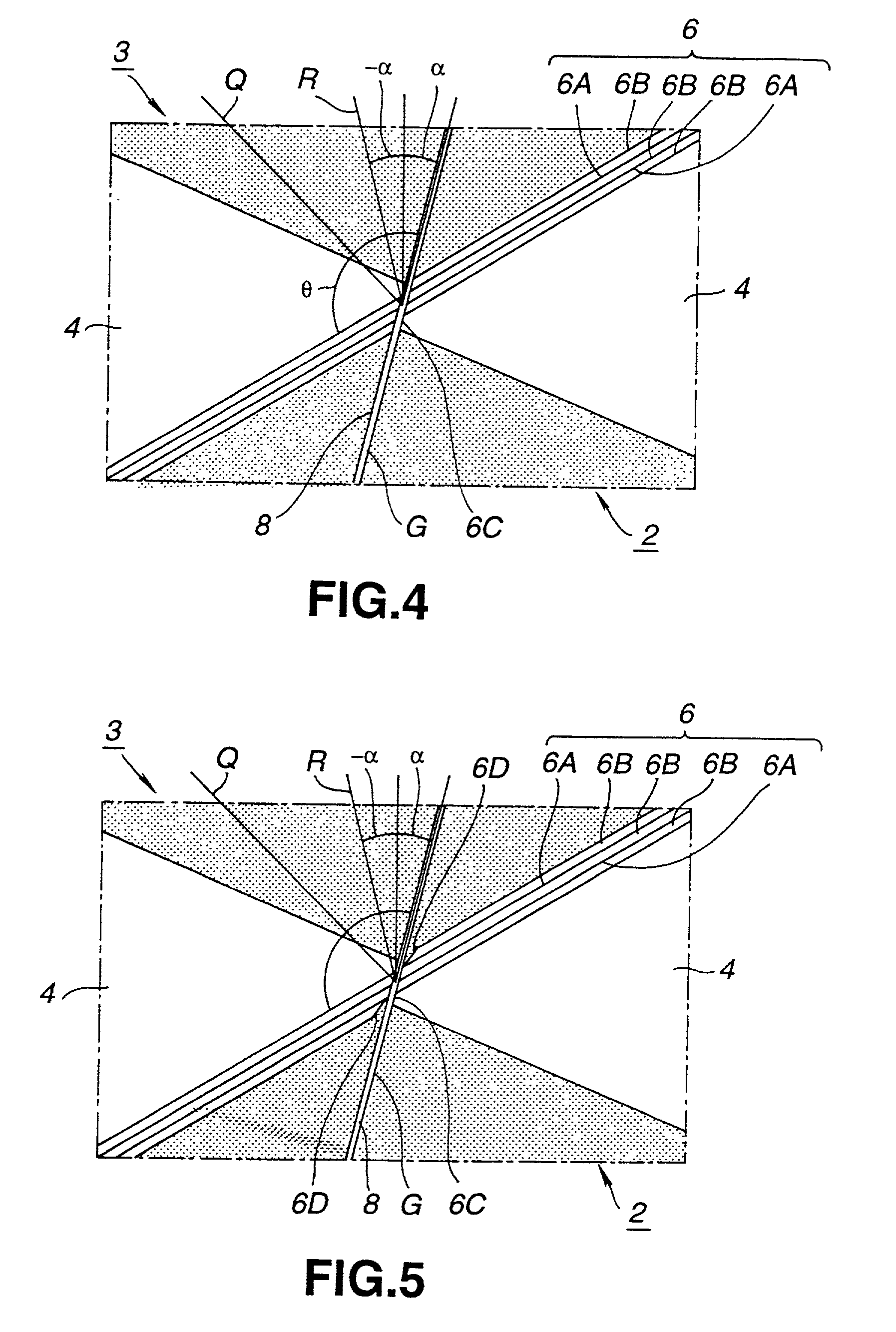

[0044] A magnetic head 1 according to the present invention is made up of a pair of magnetic head halves 2, 3 bonded together with a non-magnetic gap material G in-between, as shown in FIGS. 3 and 4. These magnetic head halves 2, 3 are each made up of a non-magnetic substrate 4 and a magnetic metal film 6 formed thereon. On at least one of the paired magnetic head halves 2, 3 is formed a coil 7 for magnetic excitation or detection of an induced voltage. In this magnetic head 1, the magnetic metal film 6 forms a magnetic core in such a state in which the paired magnetic head halves 2, 3 are bonded together with the gap material G in-between. On the magnetic head 1 is slid a magnetic recording medium in a direction shown by arrow A in FIG. 3, with the magnetic head halves 2, 3 being bonded together, thus reproducing the signal magnetic field recorde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| track offset angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap