Safety lockout for actuator shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

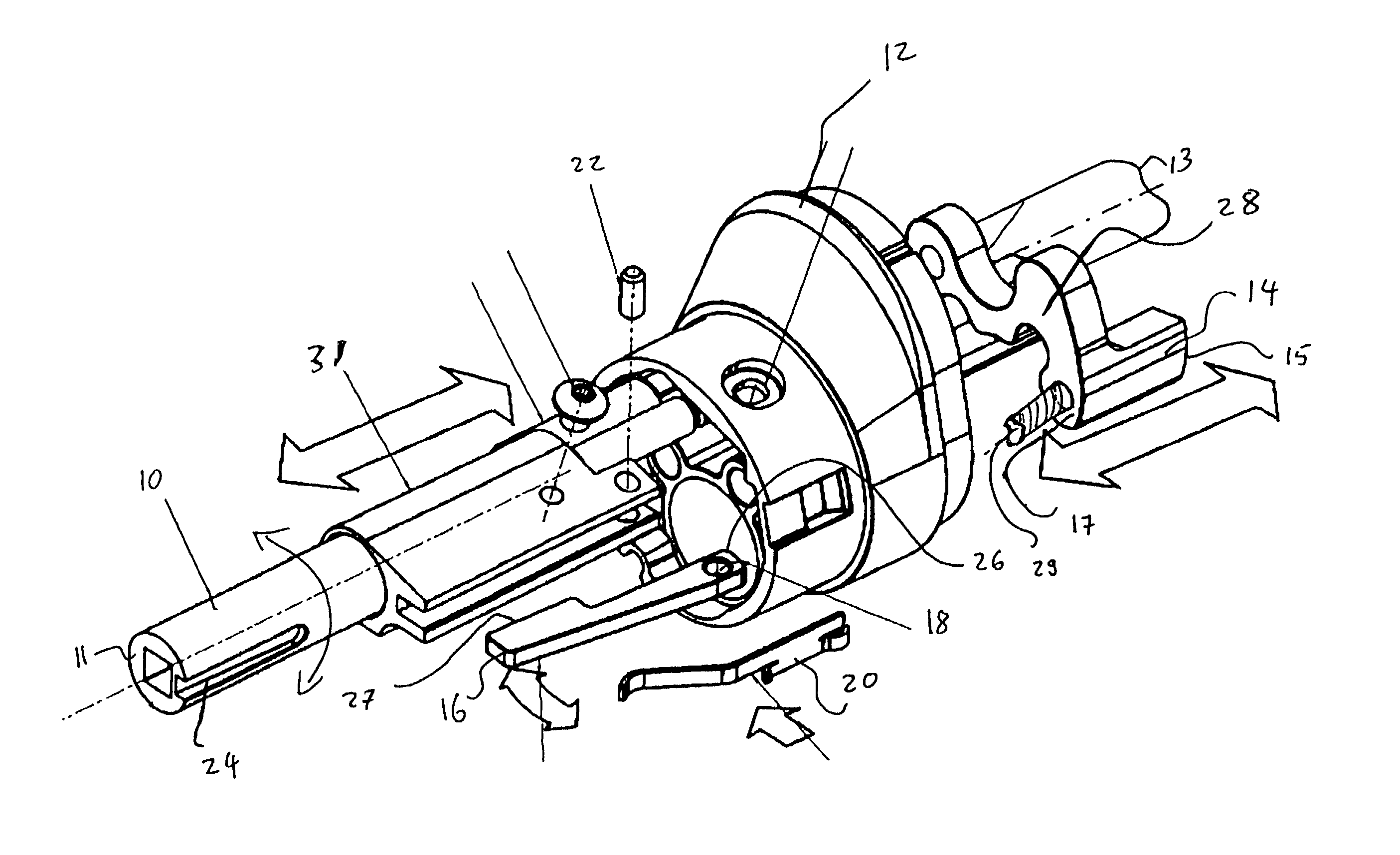

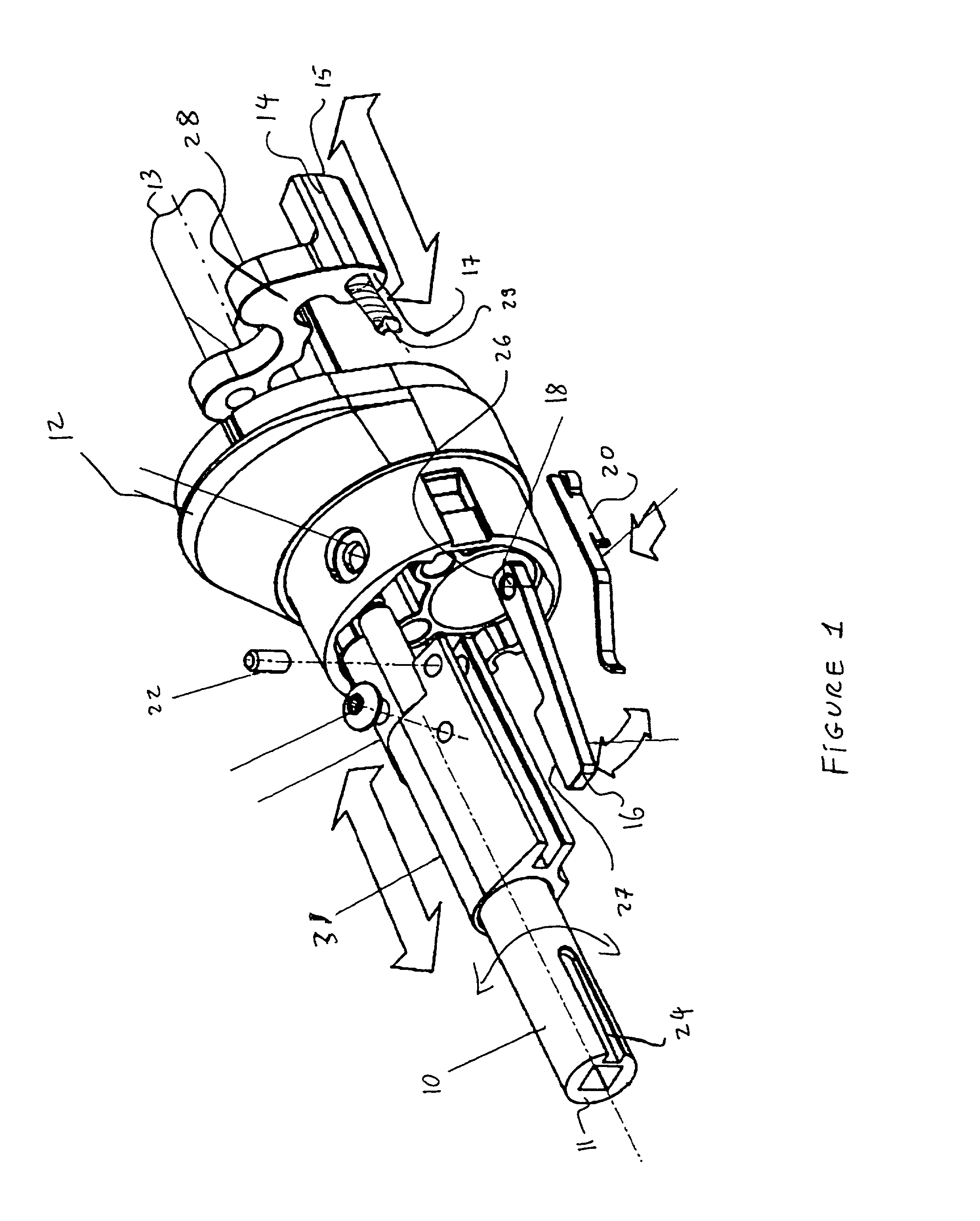

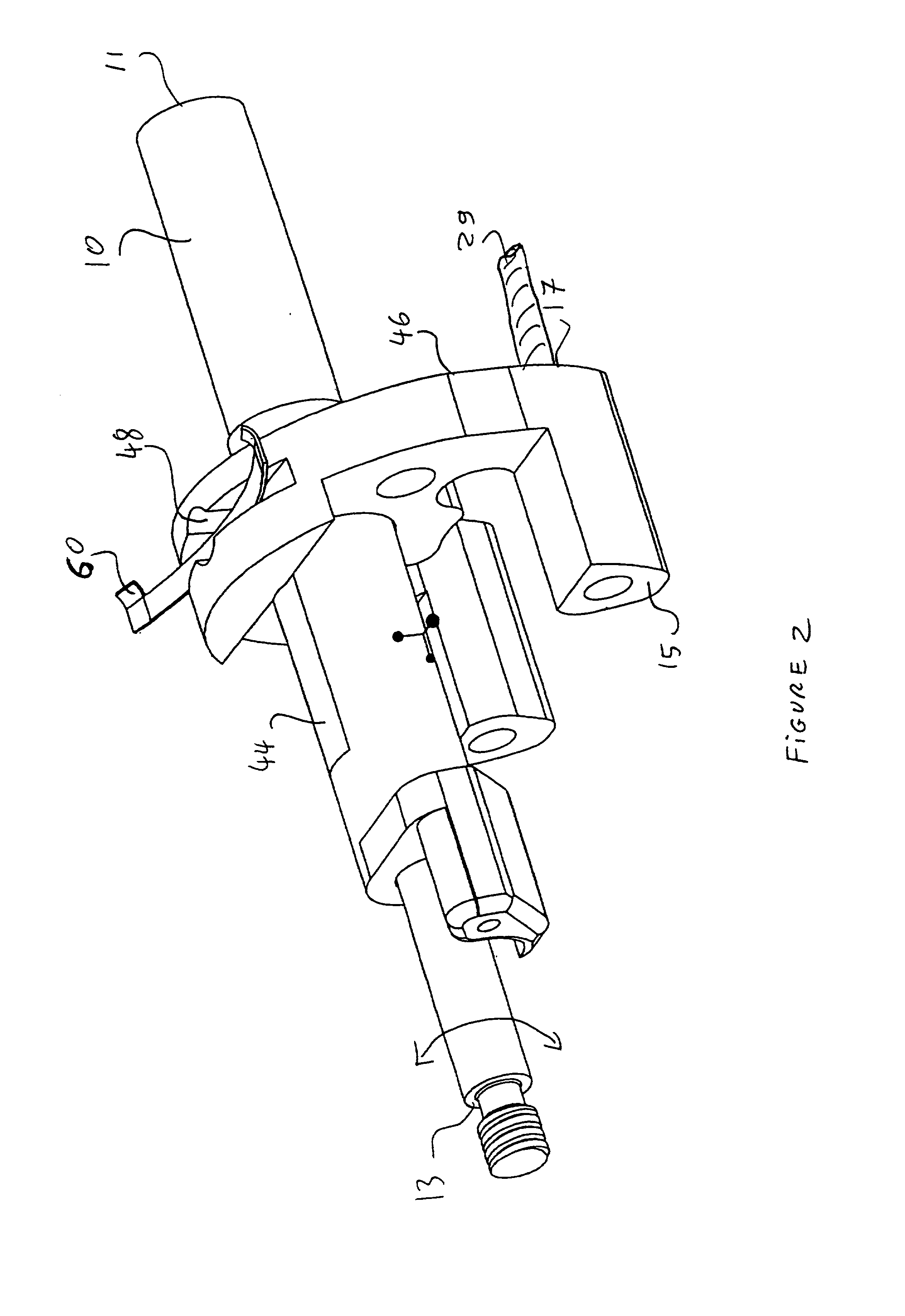

[0021] FIG. 1 shows an embodiment of the safety lockout according to the present invention, used to prevent rotation of a actuating shaft of a Full Thickness Resectioning Device. This assembly is located at a distal end of the FTRD, and forms part of the head section of the FTRD. A shaft 10 extends through the distal head section of the FTRD, and can be connected at end 11 to a flexible drive shaft (not shown) extending to the proximate end of the FTRD. Shaft 10 also has another end 13 that extends into a stapling head portion of the FTRD, not shown in the drawing, from which the staples are propelled into the tissue.

[0022] The surgeon operating the device can remotely rotate shaft 10 so that the mechanism of the stapling head connected to end 13 of shaft 10 fires a staple into the tissue when a sufficient rotation of shaft 10 has occurred. A frame 12 supports shaft 10 so that it can rotate and, if necessary, translate within frame 12. In one embodiment, frame 12 can be the rear tai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com