Smoking pipe

a technology of smoke pipe and pipe body, which is applied in the direction of tobacco pipes, applications, tobacco, etc., can solve the problems of high production cost, fragile and easily broken, and new smoking devices in which the smoke of the smoking material is drawn through water before inhalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

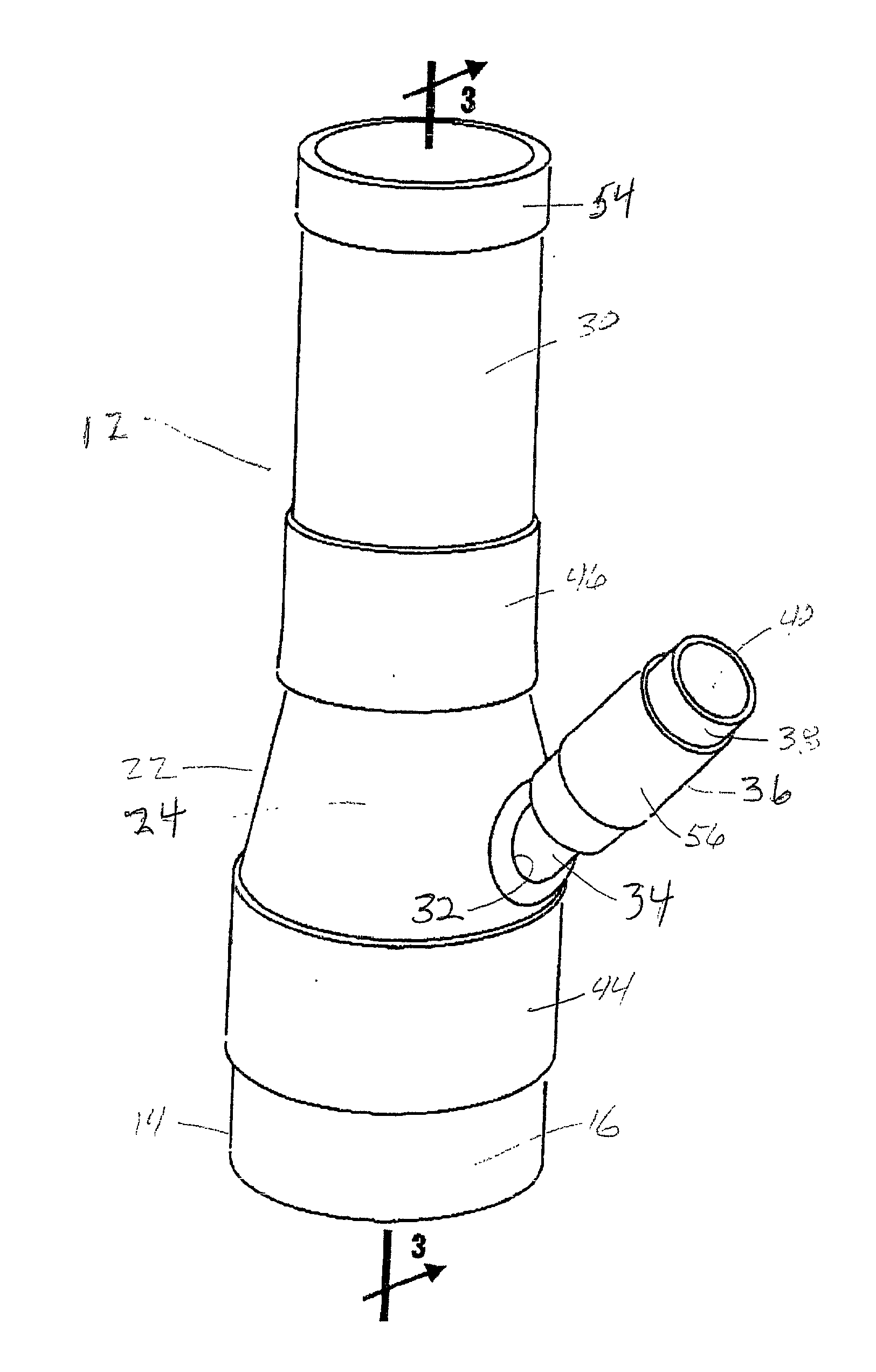

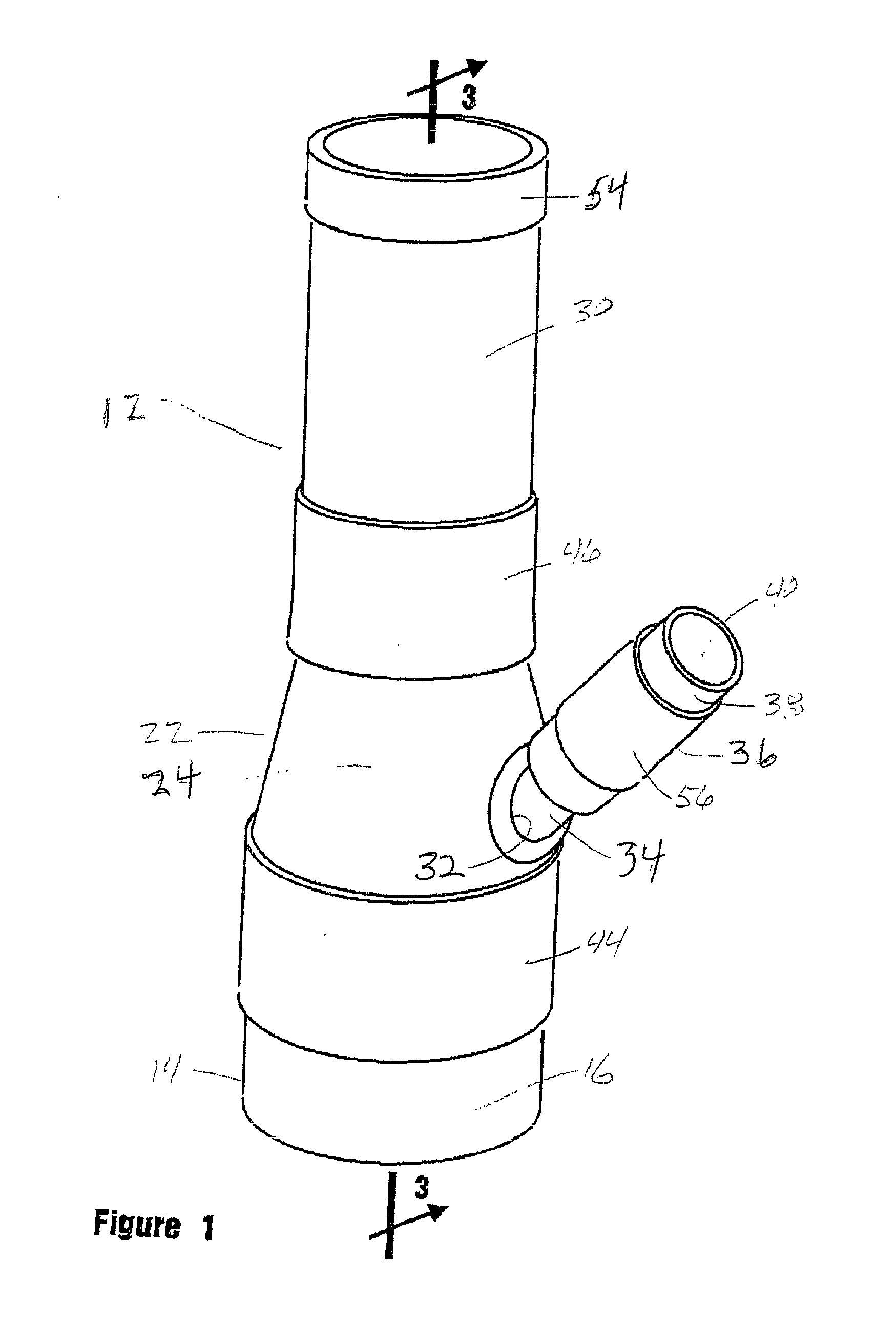

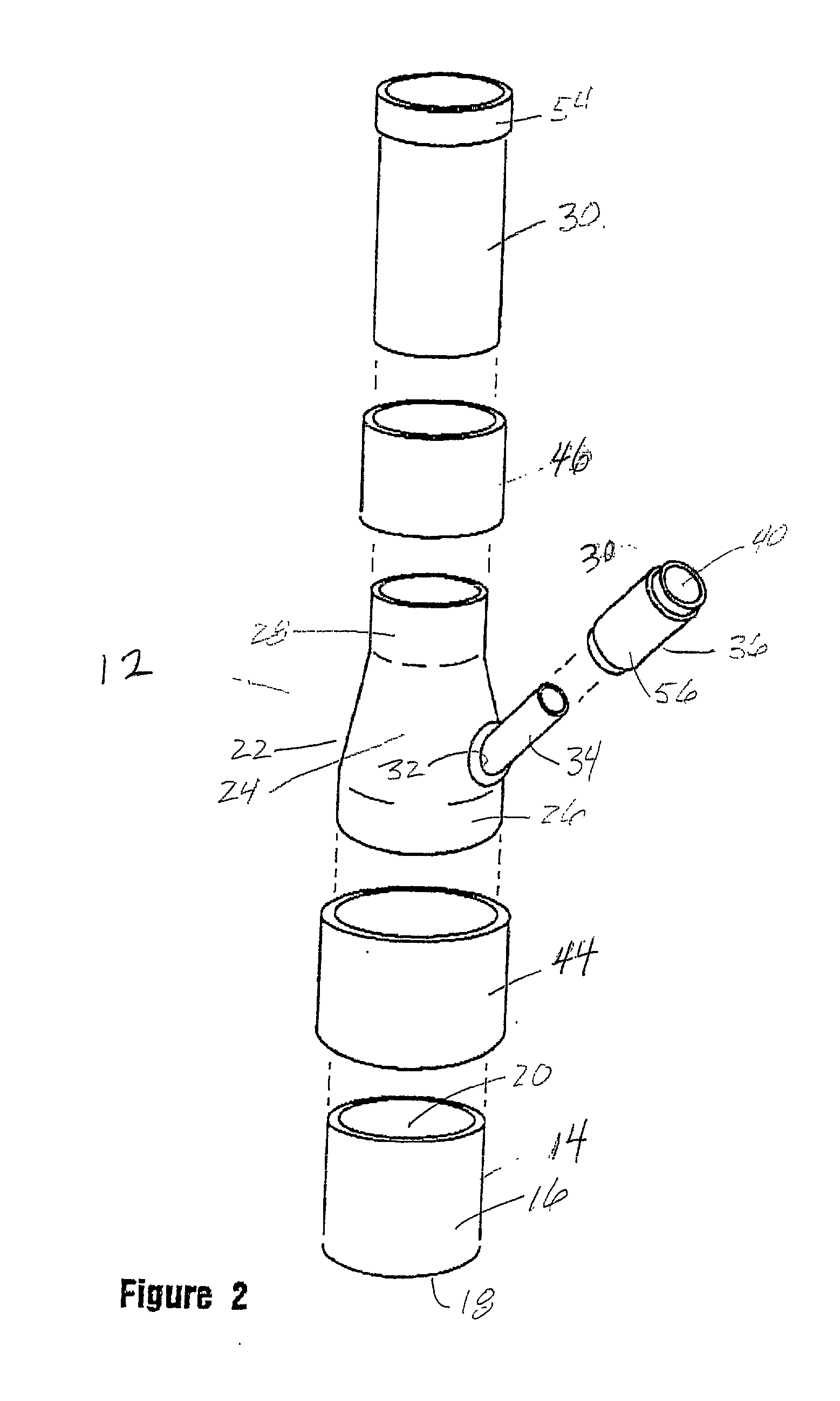

[0015] Referring to the drawings and particularly to FIGS. 1 and 2, one form of the smoking pipe of the present invention is there illustrated and generally designated by the numeral 12. As best seen by referring to FIG. 2, the smoking pipe here comprises a generally cup-shaped, stainless-steel, liquid-containing component 14 having a side wall 16 and a bottom wall that cooperate to define a liquid containing chamber 20. Slidably interconnected to liquid containing component 14 is a stainless steel connector segment 22 having a tapered side wall 24. Tapered side wall 24 interconnects and spans a first, generally cylindrically shaped skirt portion 26 that telescopically receives the generally cylindrically shaped wall 16 of the liquid containing component. Connected at the upper extremity of tapered side wall 24 is a second generally cylindrically shaped skirt portion 28 which is telescopically received within an upwardly extending, generally cylindrically shaped, stainless-steel mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com